High-concentration molybdenum-doped tungsten trioxide photocatalytic nano material and preparation method and application thereof

A technology of tungsten trioxide and nanomaterials, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve low photocatalytic efficiency and reduce electron-hole recombination Insufficient utilization rate and solar light utilization rate, etc., to achieve the effect of improving utilization rate, enhancing absorption width, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

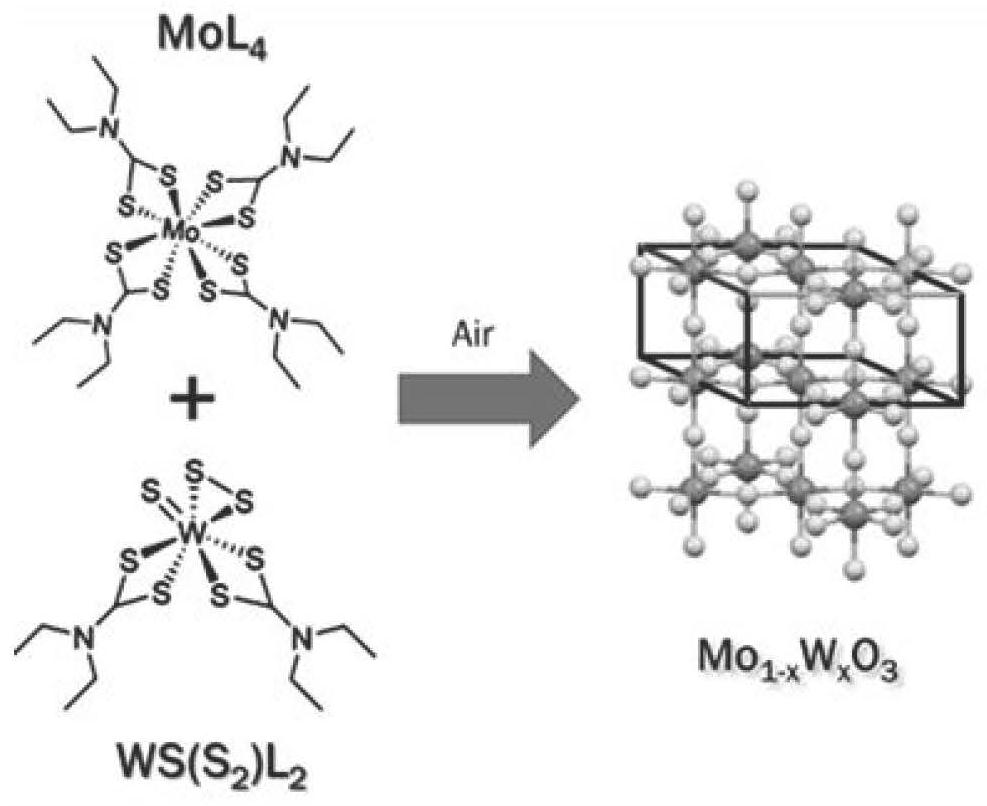

[0034] One aspect of the present invention provides a method for preparing a high-concentration molybdenum-doped tungsten trioxide photocatalytic nanomaterial, the method comprising the following steps:

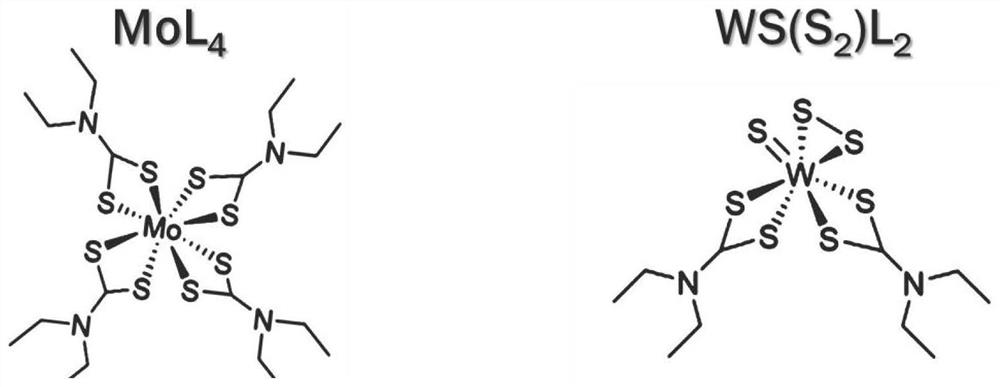

[0035] (1) Reaction of molybdenum hexacarbonyl and tetraethylthiuram disulfide to obtain molybdenum precursor MoL 4 ;

[0036] (2) React ammonium tetrathiotungstate and sodium diethyldithiocarbamate to obtain tungsten precursor WS(S 2 ) L 2 ;

[0037] (3) Mix molybdenum precursor and tungsten precursor, then heat for pyrolysis reaction, and obtain nano-doped powder material Mo after cooling 1-x W x o 3 (0.25≤x≤0.75);

[0038] (4) Optionally, the nano-doped powder material Mo 1-x W x o 3 (0.25≤x≤0.75) Ultrasound and centrifugation to obtain high-concentration molybdenum-doped tungsten trioxide nano-solution or suspension Mo 1-x W x o 3 (0.25≤x≤0.75);

[0039] Among them, MoL 4 and WS(S 2 ) L 2 L in is S 2 CN(C 2 h 5 ) 2 .

[0040] The present invention prepa...

Embodiment 1

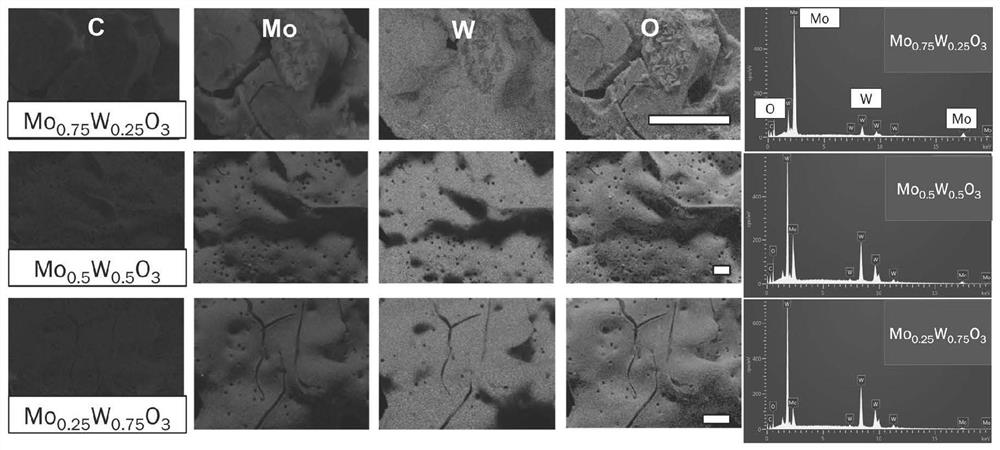

[0061] Compound A and compound B were mixed according to molybdenum / tungsten molar ratio of 1:3, put into a tube furnace and heated to 500°C, the whole reaction was kept in the air environment for 1 hour, then cooled to room temperature and the reaction product was collected to obtain the molecular formula For Mo 0.25 W 0.75 o 3 nano-doped materials.

[0062] The scanning electron microscope image and corresponding energy spectrum image of the nano-doped material prepared in this example, the ultra-high resolution scanning transmission electron microscope image and its corresponding nanoparticle size distribution, Raman spectrum and X-ray diffraction image, photocatalytic degradation of formazan Degradation photo of base orange as Figure 3-6 shown.

Embodiment 2

[0064] Compound A and compound B were mixed according to the molybdenum / tungsten molar ratio of 1:1, put into a tube furnace and heated to 450°C, the whole reaction was kept in the air environment for 4 hours, then cooled to room temperature and the reaction product was collected to obtain the molecular formula For Mo 0.5 W 0.5 o 3 nano-doped materials.

[0065] The scanning electron microscope image and corresponding energy spectrum image of the nano-doped material prepared in this example, the ultra-high resolution scanning transmission electron microscope image and its corresponding nanoparticle size distribution, Raman spectrum and X-ray diffraction image, photocatalytic degradation of formazan Degradation photo of base orange as Figure 3-6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com