Manufacturing method for pure tungsten or molybdenum thin-wall device

A device and thin-wall technology, which is applied in the field of preparation of pure tungsten or molybdenum thin-wall devices, can solve the problems of expensive tungsten fluoride, limited practical application, equipment corrosion, etc., and achieves short processing flow, dense film layer, and deposition speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

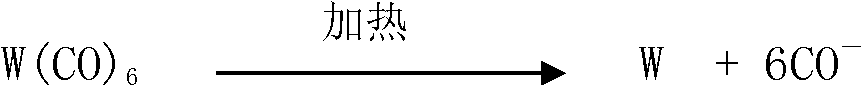

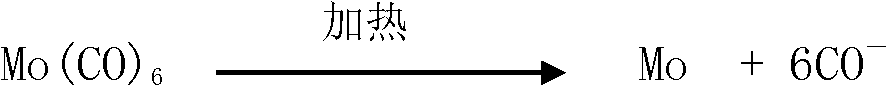

Method used

Image

Examples

Embodiment 1

[0017] Use copper material to process pipe fittings with an outer diameter of 50 mm, a wall thickness of 1 mm, and a height of 50 mm. The surface roughness Ra is 0.8, and then the oil on the surface is cleaned and dried. Put the copper pipe fitting template into the vapor deposition chamber, and evacuate the system to a vacuum of 0.5Pa, then preheat the copper pipe fitting to 400°C. Use tungsten hexacarbonyl as the organic source of reaction (gasified at 80°C), 5N hydrogen as the diluent gas, keep the volume flow ratio of tungsten hexacarbonyl and hydrogen at 1:10, and pass the mixed gas into the deposition chamber. Keeping the deposition chamber pressure at 500Pa and the deposition temperature at 400°C, tungsten hexacarbonyl was subjected to thermal dissociation vapor deposition on the red copper template for 4 hours, and then annealed at 900°C for 10 minutes. After the deposition is completed, close the valve of the organic source, and continue to feed hydrogen to keep the d...

Embodiment 2

[0019] Process a crucible with an outer diameter of 5mm, a wall thickness of 1mm, and a height of 50mm with red copper material, and its surface roughness Ra is 1.6, and then the oil stain on the surface is cleaned and dried. Put the copper crucible template into the vapor deposition chamber, and evacuate the system to a vacuum of 2Pa, then preheat the copper crucible to 280°C. Use tungsten hexacarbonyl as the organic source of reaction (gasified at 90°C), 5N hydrogen as the diluent gas, keep the volume flow ratio of tungsten hexacarbonyl and hydrogen at 1:100, and pass the mixed gas into the deposition chamber. The thermal dissociation vapor deposition of tungsten hexacarbonyl on the red copper template was carried out under the condition of maintaining the deposition chamber pressure of 5000Pa and the deposition temperature of 280°C, annealing at 800°C for 20 minutes every 4 hours of deposition, and a total of 182 hours of vapor deposition. After the deposition is completed,...

Embodiment 3

[0021] Use copper material to process pipe fittings with an outer diameter of 5 mm, a wall thickness of 1 mm, and a height of 50 mm. The surface roughness Ra is 3.2, and then the oil on the surface is cleaned and dried. Put the copper pipe fitting template into the vapor deposition chamber, and evacuate the system to a vacuum of 5Pa, then preheat the copper pipe fitting to 360°C. Use tungsten hexacarbonyl as the reactive organic source (gasified at 90°C), 5N nitrogen as the diluent gas, keep the volume flow ratio of tungsten hexacarbonyl and nitrogen at 1:50, and pass the mixed gas into the deposition chamber. Keep the deposition chamber pressure at 10,000 Pa and the deposition temperature at 360°C for thermal dissociation vapor deposition of tungsten hexacarbonyl on the copper template, annealing at 700°C for 30 minutes every 2 hours of deposition, and a total of 142 hours of vapor deposition. After the deposition is completed, close the valve of the organic source, and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com