Molybdenum ditelluride electrochemical energy storage material, preparation method and application thereof

A technology of molybdenum ditelluride and energy storage materials, which is applied in the direction of binary selenium/telluride compounds, metal selenide/telluride, etc., can solve the problem of no supercapacitor material application of molybdenum ditelluride, and achieve good electrochemical storage Performance and electrochemical stability, and the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of molybdenum ditelluride nanoflower structure electrochemical energy storage materials

[0040] (1) Preparation of 1 mol / L Te-TOP precursor: 638 mg (0.5 mmol) metallic tellurium was added to a round-bottomed flask containing 5 ml trioctylphosphine, stirred and dissolved at 100 °C for 5 h to obtain Te -TOP precursor.

[0041] (2) Add 66 mg (0.25 mmol) molybdenum hexacarbonyl and 15 ml oleylamine to a 100 mL three-neck round bottom flask, heat up to 80 °C under stirring, degas under vacuum for 30 min, and inject the Te- TOP precursor 0.5 mL, then, under the protection of argon at 5 ℃ min -1 The heating rate was increased to 320 °C, and the reaction was carried out for 2 h. Cool to room temperature after the reaction, add toluene and absolute ethanol with a volume ratio of 1:1 to wash three times, and finally disperse in ethanol to obtain molybdenum ditelluride nanoflowers assembled by ultrathin nanosheets.

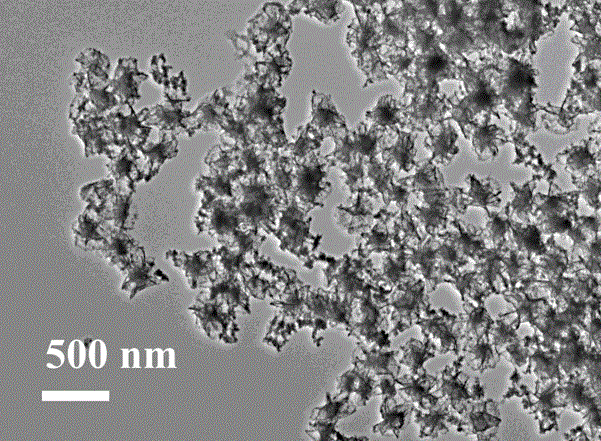

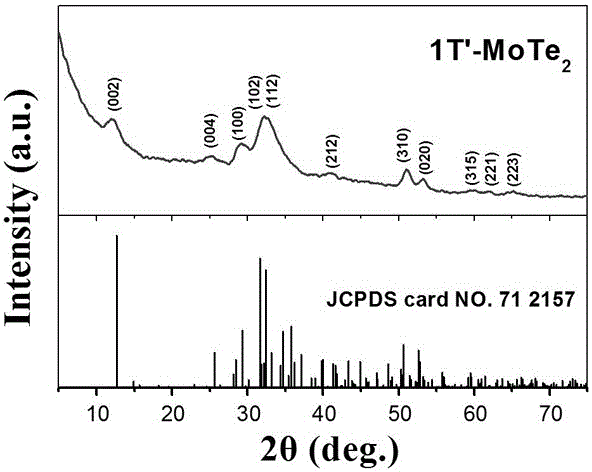

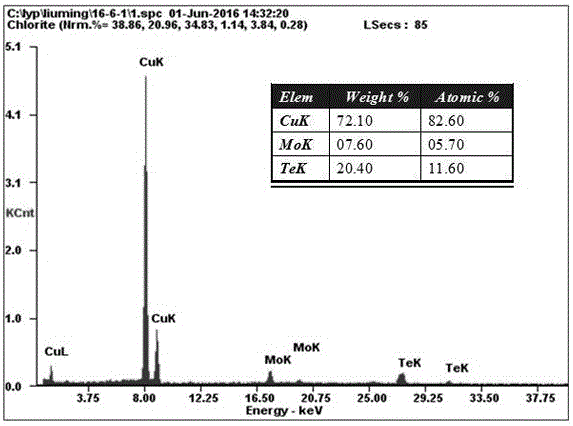

[0042] Picture 1-1 This is the TEM picture of t...

Embodiment 2

[0049] Preparation of molybdenum ditelluride nanosphere structure electrochemical energy storage materials

[0050] (1) Preparation of 1 mol / L Te-TOP precursor: 638 mg (0.5 mmol) metallic tellurium was added to a round-bottomed flask containing 5 mL trioctylphosphine, stirred and dissolved at 100 °C for 5 h to obtain Te -TOP precursor.

[0051] (2) Add 68 mg (0.25 mmol) molybdenum pentachloride and 15 mL oleylamine to a 100 mL three-neck round bottom flask, heat up to 80 °C under stirring, degas under vacuum for 30 min, and inject the Te synthesized above under an argon atmosphere. -TOP precursor 0.5 mL, then, under the protection of argon at 5 ℃ min -1 The heating rate was increased to 320 °C, and the reaction was carried out for 2 h. Cool to room temperature after the reaction, add toluene and absolute ethanol at a volume ratio of 1:1 to wash three times, and finally disperse in ethanol to obtain molybdenum ditelluride nanospheres assembled by ultrathin nanosheets.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com