Graphene/poly (3, 4-ethylenedioxythiophene) self-supporting film and preparation method thereof

A technology of ethylenedioxythiophene and self-supporting film, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, can solve the problems of high cost of current collectors, poor cycle stability, and poor specific capacity, and achieve the goal of reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

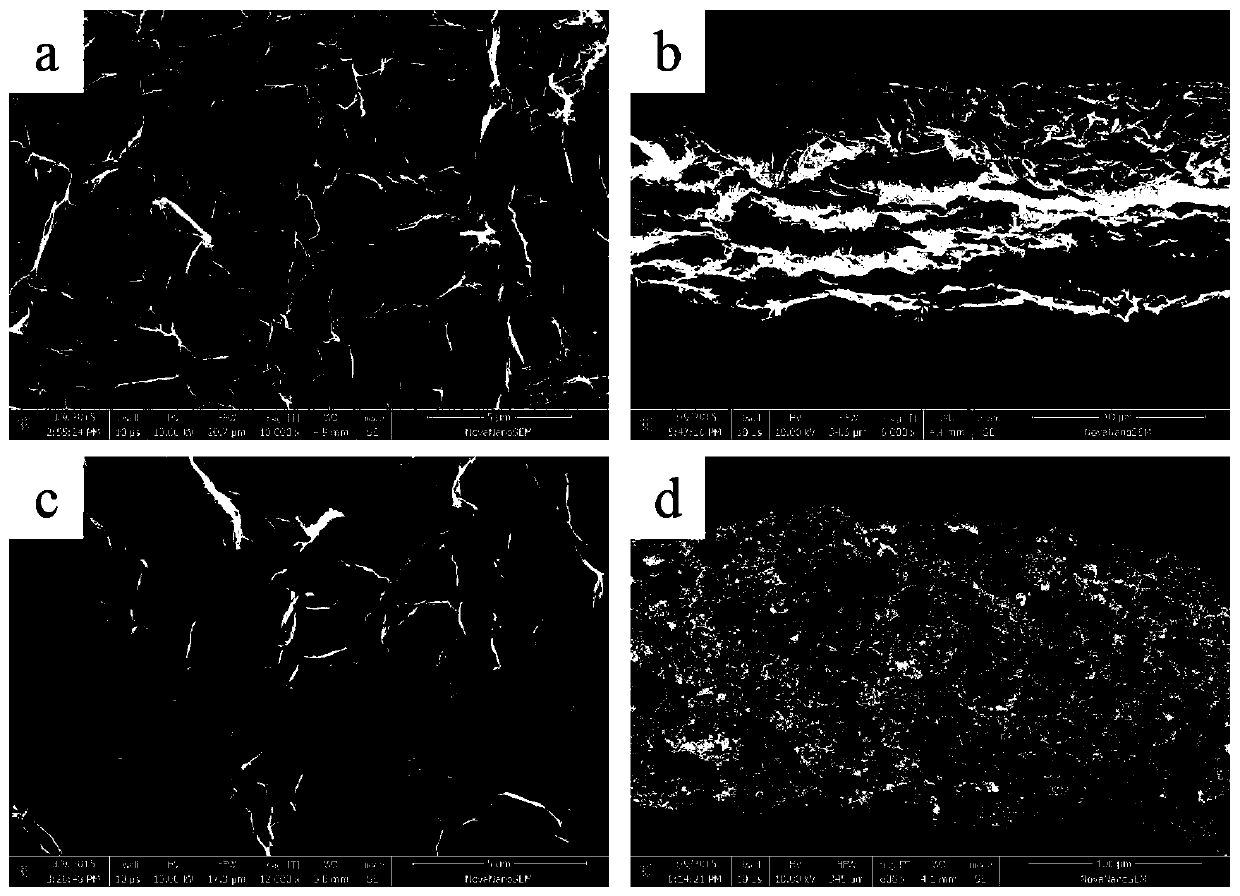

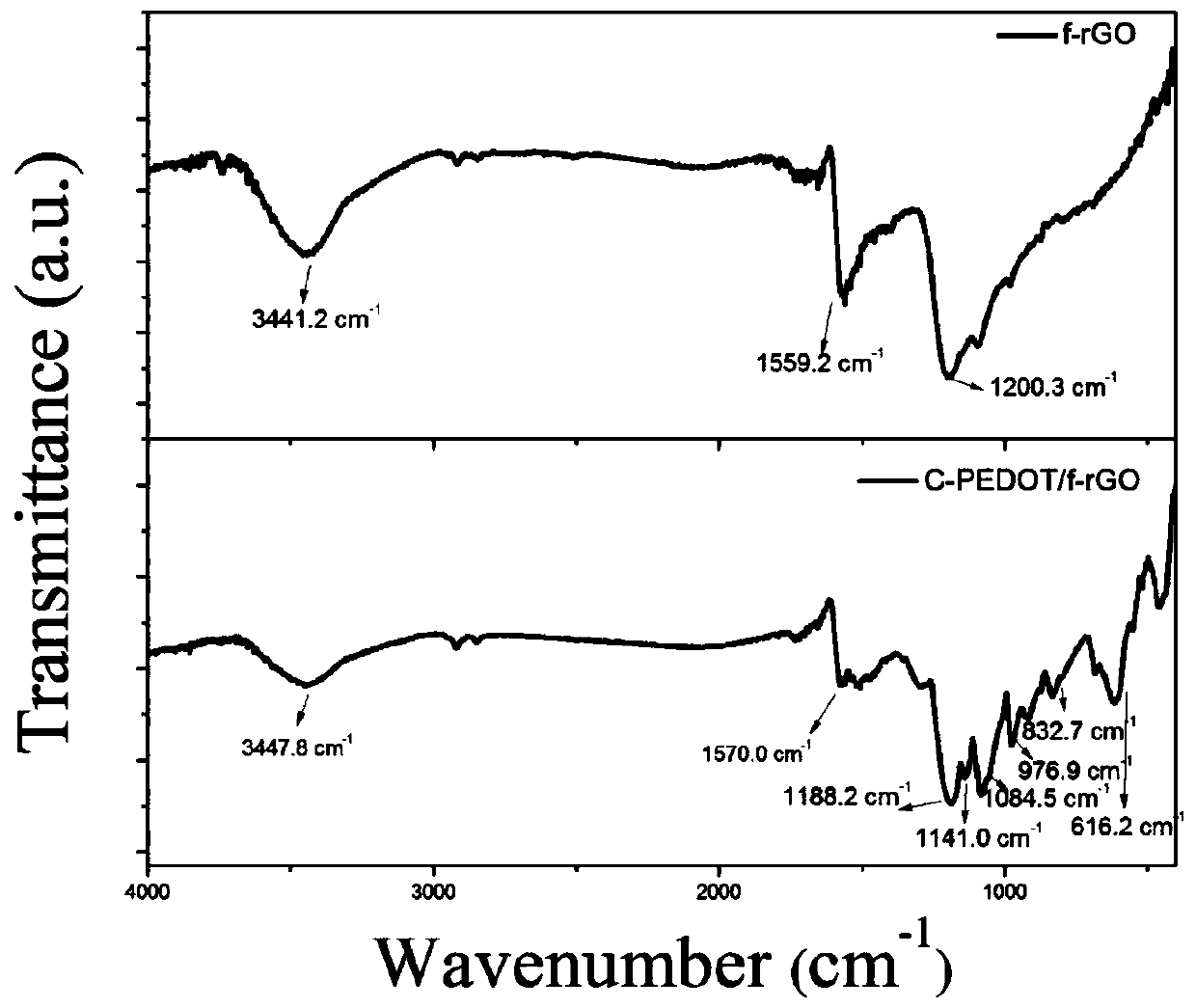

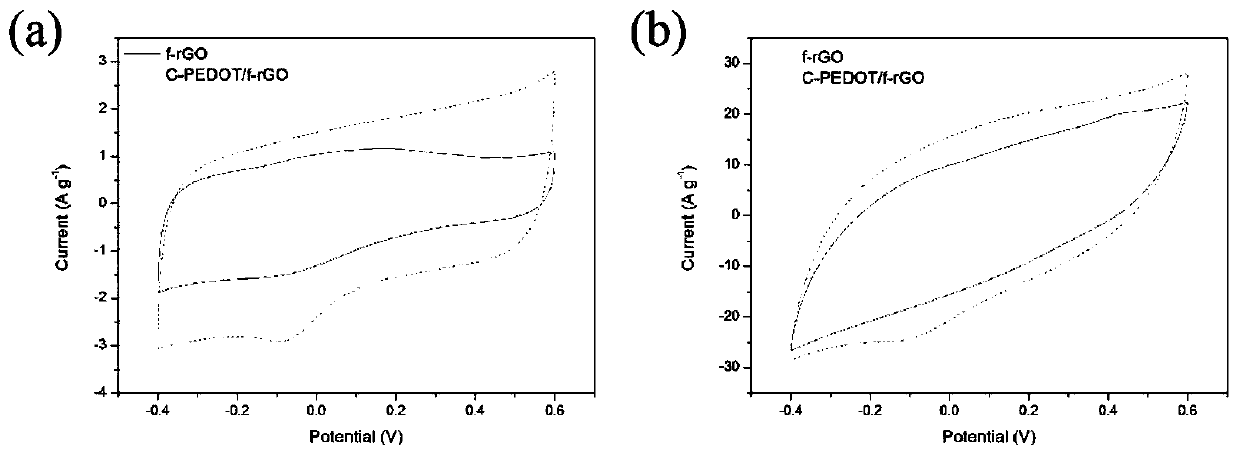

[0031] Add flake graphite powder to H 2 SO 4 Add potassium persulfate and phosphorus pentoxide slowly, and stir at 70°C, filter and wash the reaction mixture with deionized water, and dry to obtain the pre-oxidized product; add the pre-oxidized product and sodium nitrate to H 2 SO 4 , add KMnO under ice-water bath 4 , stirred at 30°C for 3 hours, took it out and put it in an ice-water bath, added 100mL of deionized water and 4mL of H 2 o 2 , using deionized water for centrifugal washing, adding a certain amount of deionized water to obtain a graphene oxide aqueous dispersion.

[0032] 10mg·mL in 3mL -1 Add 3,4-ethylenedioxythiophene monomer to the graphene oxide according to the mass ratio of graphene oxide to 3,4-ethylenedioxythiophene of 10:1, and stir for 30 minutes to obtain a mixed dispersion. Add 2mgFeCl to it 3 , shaking to form graphene oxide hydrogel. Also use a scraper with a height of 520 μm to scrape the graphene oxide hydrogel on the hydrophilic glass subs...

Embodiment 2

[0039] Add flake graphite powder to H 2 SO 4 Add potassium persulfate and phosphorus pentoxide slowly, and stir at 90°C, filter and wash the reaction mixture with deionized water, and dry to obtain the pre-oxidized product; add the pre-oxidized product and sodium nitrate to H 2 SO 4 , add KMnO under ice-water bath 4 , stirred at 30-50°C for 2 hours, took it out and put it in an ice-water bath, added 80mL of deionized water and 4mL of H 2 o 2 , using deionized water for centrifugal washing, adding a certain amount of deionized water to obtain a graphene oxide aqueous dispersion.

[0040] 5mg·mL in 4mL -1 3,4-ethylenedioxythiophene monomer was added to the graphene oxide according to the mass ratio of graphene oxide and 3,4-ethylenedioxythiophene being 10:2, and stirred for 30 minutes to obtain a mixed dispersion. Add 3mgFeCl to it 3 , shaking to form graphene oxide hydrogel. Also use a scraper with a height of 520 μm to scrape the graphene oxide hydrogel on the hydrophi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com