Multi-metal one-dimensional nano material, preparation method and catalyst

A nanomaterial and polymetallic technology, applied in the field of catalytic material preparation, can solve the problems of complicated operation process, and achieve the effects of high yield, simple and efficient preparation method and experimental operation, superior catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, a one-dimensional platinum-rhodium-cobalt-nickel quaternary alloy ultrafine nanowire is prepared, and its preparation method includes the following steps:

[0026] 1) In a 25 ml reaction flask, add 30 mg platinum acetylacetonate, 6 mg rhodium acetylacetonate, 7 mg cobalt acetylacetonate, 7 mg nickel acetylacetonate, 60 mg cetyltrimethylammonium chloride, 5 mL oleylamine, and stir at room temperature for 10 minutes, ultrasound for 10 minutes;

[0027] 2) Add 30 mg of molybdenum hexacarbonyl, place in an oil bath at 180°C for 6 hours, cool naturally to room temperature after the reaction, wash and centrifuge several times with a mixture of ethanol and n-hexane for later use.

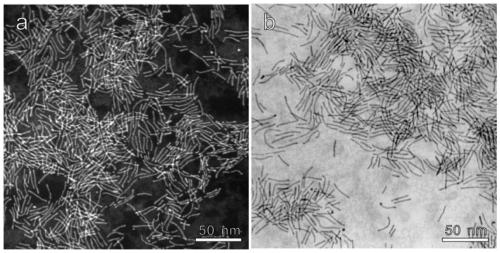

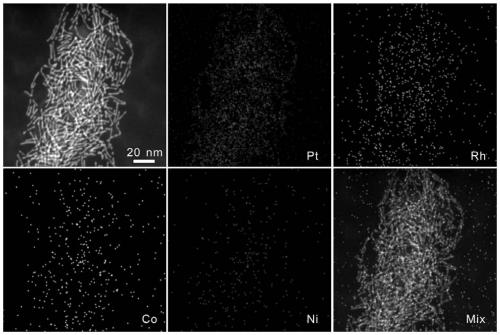

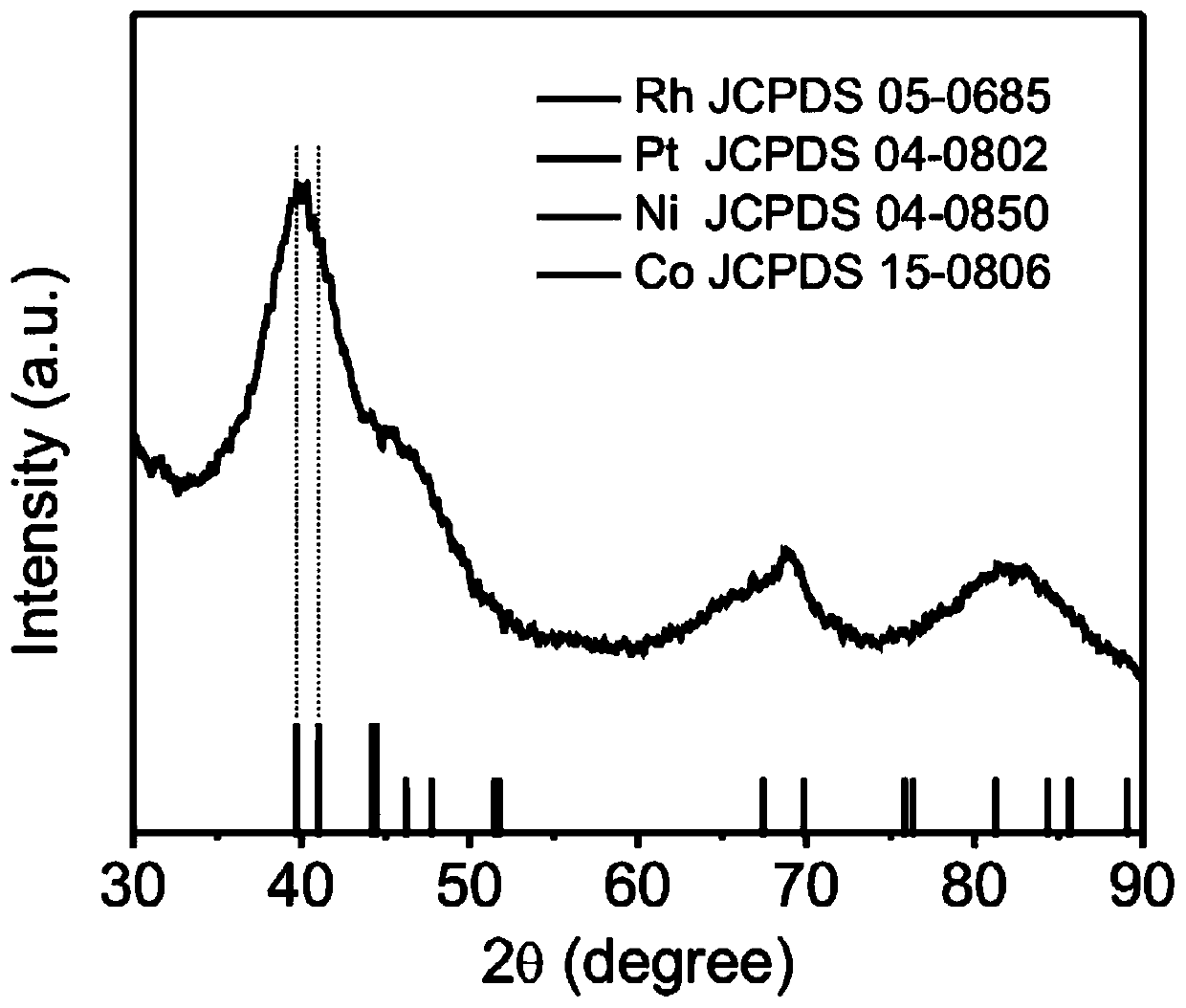

[0028] The morphology, composition and microstructure of the product are systematically studied by HAADF-STEM, TEM, XRD and other modern nano-testing and analysis techniques. HAADF-STEM, TEM( figure 1 a, b) The characterization product is a one-dimensional ultrafine nanowire st...

Embodiment 2

[0030] The difference between embodiment 2 and embodiment 1 is:

[0031] 1) In a 25 ml reaction flask, add 30 mg platinum acetylacetonate, 4 mg rhodium acetylacetonate, 7 mg cobalt acetylacetonate, 7 mg nickel acetylacetonate, 60 mg cetyltrimethylammonium chloride, 5 mL oleylamine, and stir at room temperature for 10 minutes, ultrasound for 10 minutes;

[0032] 2) Add 30 mg of molybdenum hexacarbonyl, place in an oil bath at 180°C for 6 hours, cool naturally to room temperature after the reaction, wash and centrifuge several times with a mixture of ethanol and n-hexane for later use.

Embodiment 3

[0034] The difference between embodiment 3 and embodiment 1 is:

[0035] 1) In a 25 ml reaction flask, add 30 mg platinum acetylacetonate, 2.4 mg rhodium acetylacetonate, 7 mg cobalt acetylacetonate, 7 mg nickel acetylacetonate, 60 mg cetyltrimethylammonium chloride, 5 mL oleylamine, and stir at room temperature 10 minutes, ultrasound for 10 minutes;

[0036] 2) Add 30 mg of molybdenum hexacarbonyl, place in an oil bath at 180°C for 6 hours, cool naturally to room temperature after the reaction, wash and centrifuge several times with a mixture of ethanol and n-hexane for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com