Laser pulse deposition preparation method for Cs2SnI6 thin film

A laser pulse deposition and thin film technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, ion implantation plating, etc., can solve the problems of complex chemical reaction process, easy to appear CsI impurity phase, and difficult component control, etc., to achieve The preparation process and operation are simple, the stability and repeatability are good, and the substrate coverage is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this example Cs 2 SnI 6 The preparation method of thin film is realized through the following steps:

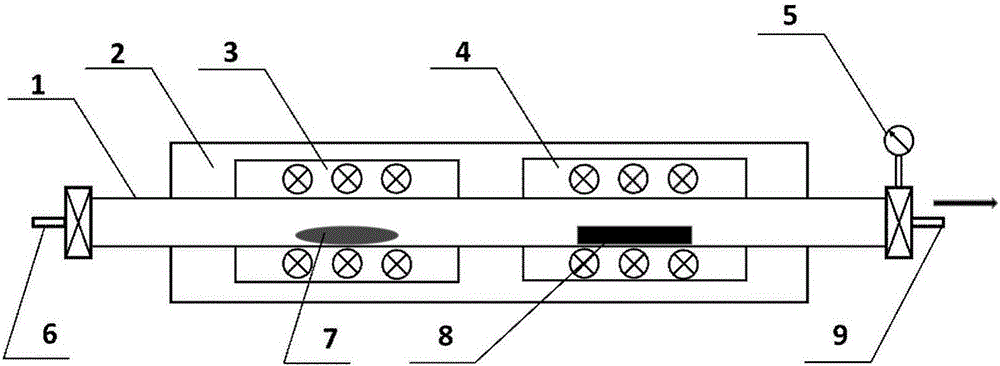

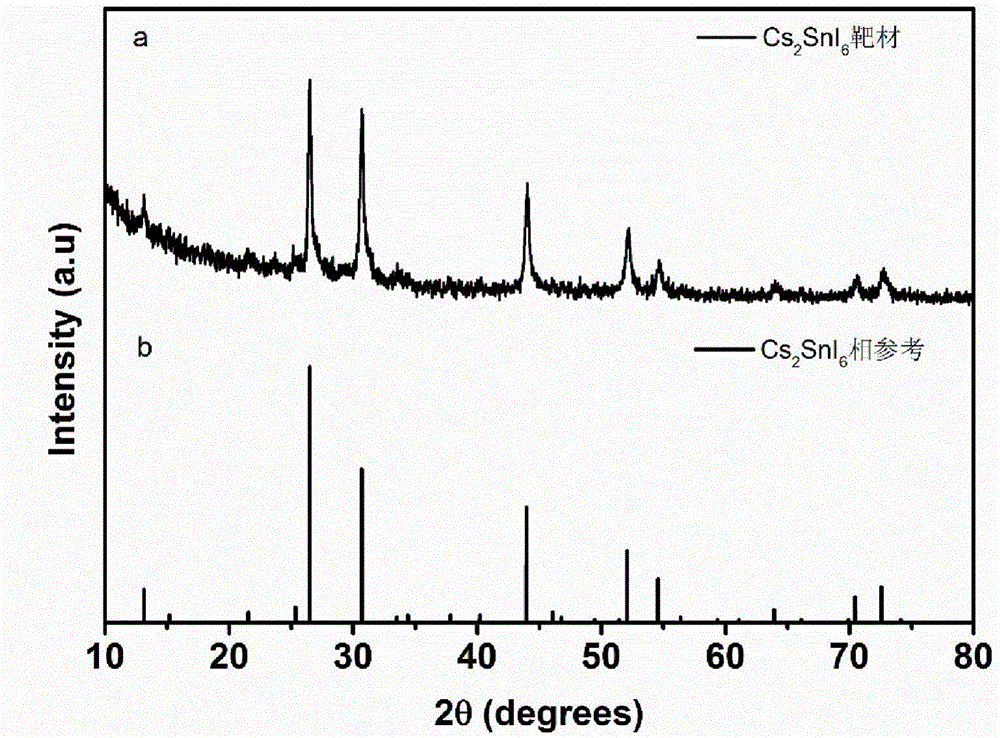

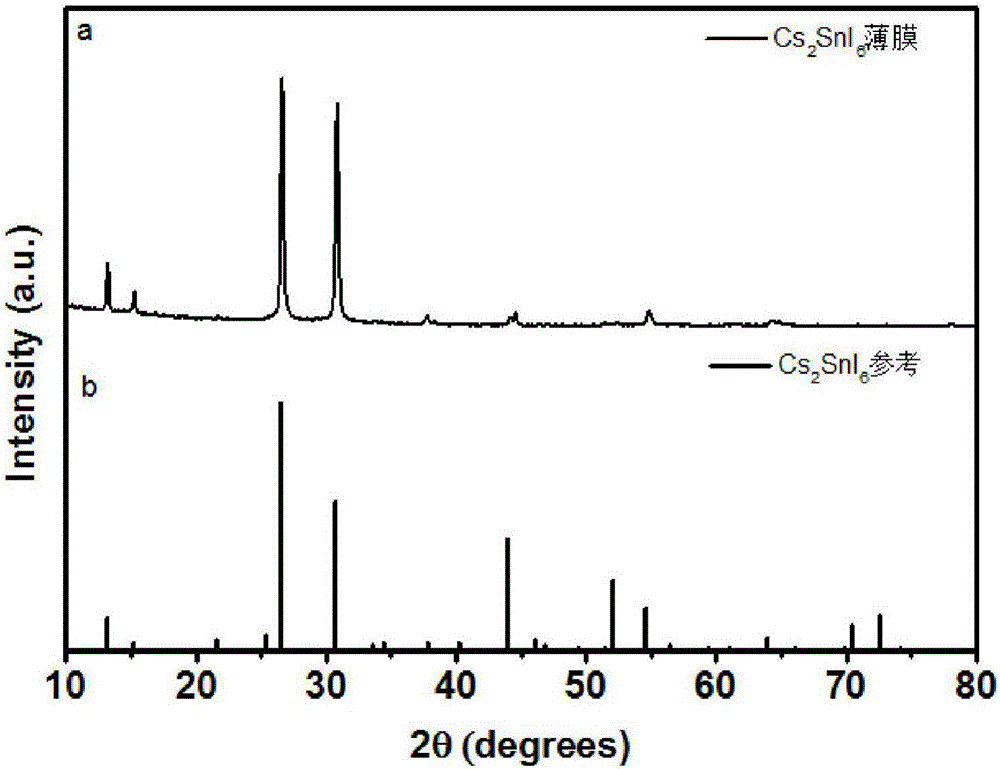

[0022] Schematic diagram of the structure of the tube furnace with dual temperature zones used in target sintering and precursor thin film annealing in this embodiment. figure 1 Shown is CsSnI synthesized by solution method 3 The powder is pressed into a cylindrical block in a two-zone tube furnace I 2 Cs obtained by sintering cylindrical bulk under atmosphere 2 SnI 6 target, and then prepared Cs on the glass substrate by the pulsed laser deposition (PLD) method 2 SnI 6 Precursor film, finally in a two-zone tube furnace I 2 Annealing Cs under atmosphere 2 SnI 6 Precursor film, the specific preparation method is:

[0023] 1. CsSnI 3 Preparation of powder: prepare 20mL of CsI aqueous solution with a concentration of 1.55M and SnCl with a concentration of 1.03M 2 Ethanol solution 10mL; SnCl 2 Add the ethanol solution to the CsI aqueous solution and continu...

Embodiment 2

[0029] This embodiment prepares Cs in the same manner as in Example 1 2 SnI 6 Film, the difference is: step 2) pressurized 2MPa.

Embodiment 3

[0031] This embodiment prepares Cs in the same manner as in Example 1 2 SnI 6 Film, the difference is: step 2) pressurized 10MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com