A kind of ultrafine copper-platinum alloy nanowire and preparation method thereof

A copper-platinum alloy and nanowire technology, applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problem of limited shape of platinum-based alloy nanoparticles, and achieve excellent catalytic activity, good crystal form, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

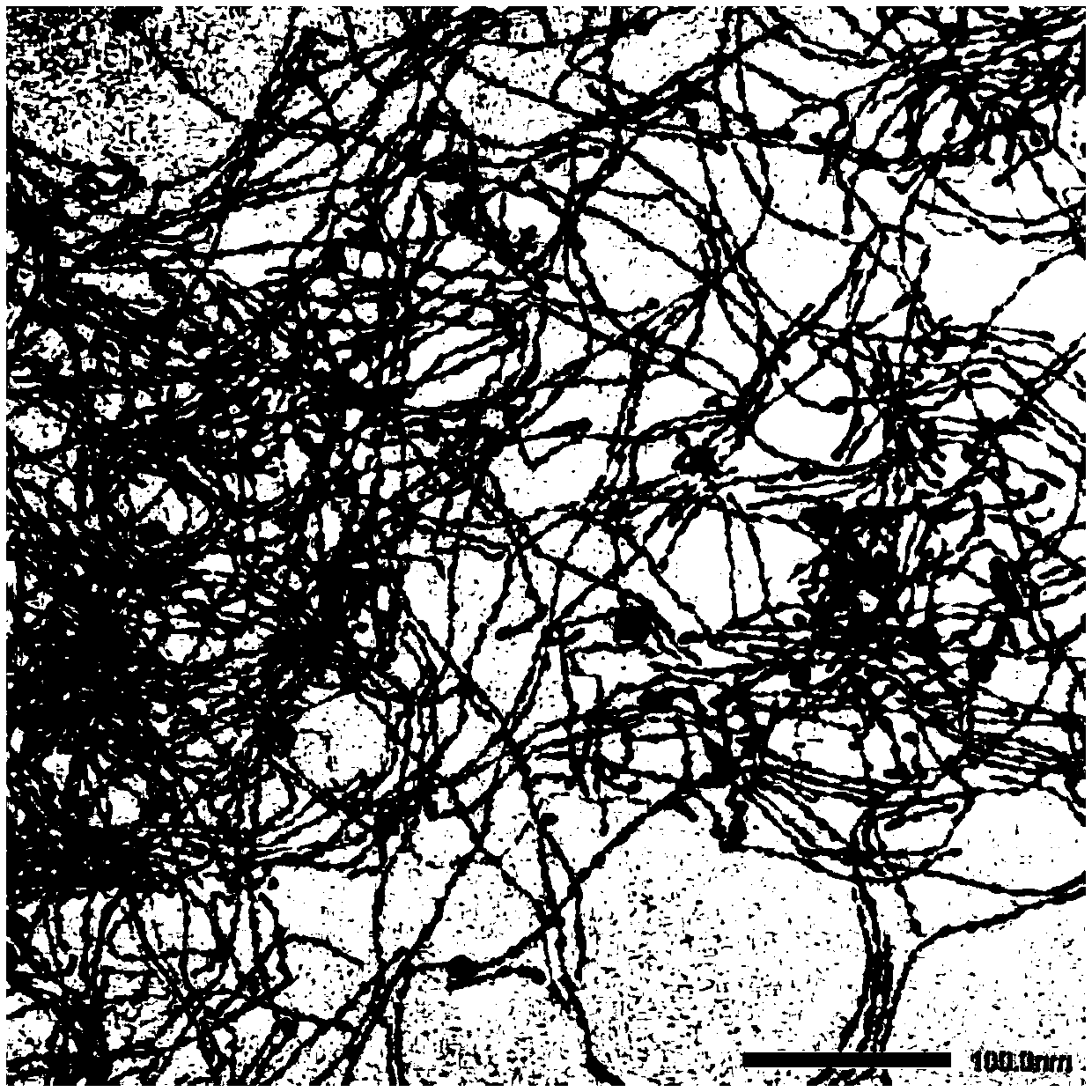

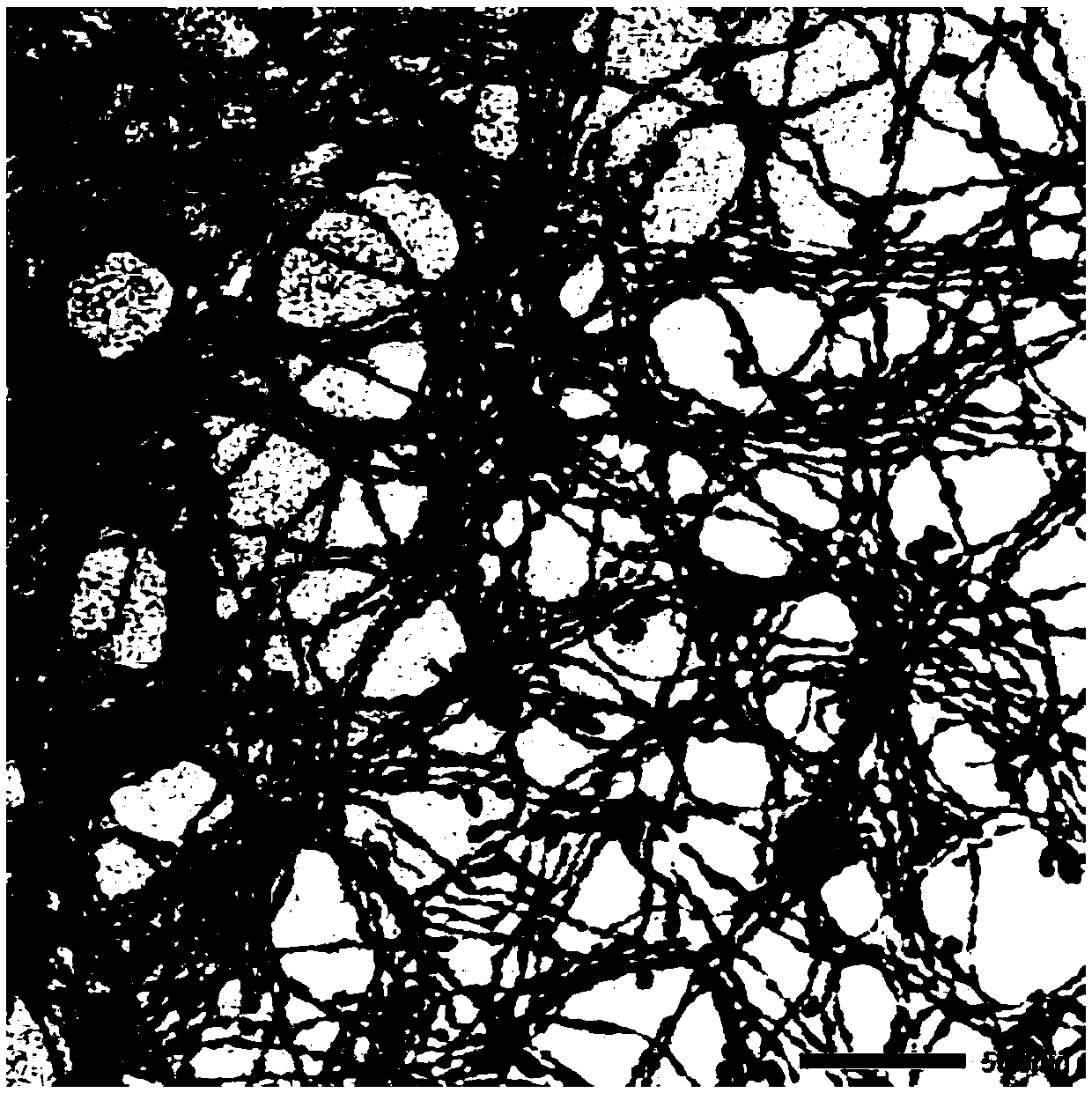

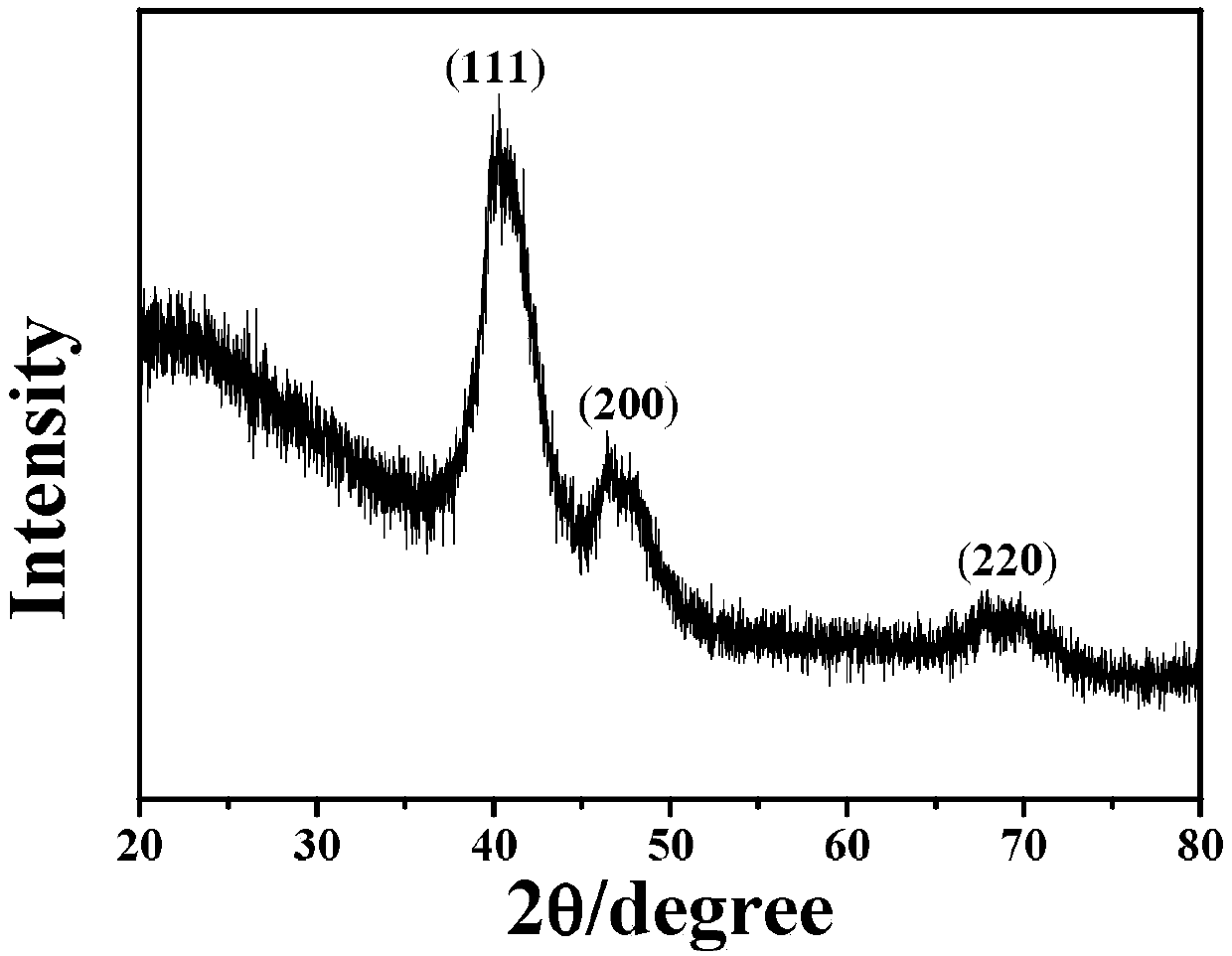

[0017] Embodiment 1: The ultrafine copper-platinum alloy nanowires in this embodiment have a diameter of 3 nm to 5 nm and a length of 1.5 μm to 3 μm.

specific Embodiment approach 2

[0018] Specific embodiment two: the preparation method of the ultra-fine copper-platinum alloy nanowire described in specific embodiment one is carried out according to the following steps:

[0019] 1. Weigh platinum acetylacetonate, molybdenum hexacarbonyl and hexadecyltrimethylammonium chloride (CTAC) at a mass ratio of 1: (0.25-0.75): (1.5-2) to weigh platinum acetylacetonate and molybdenum hexacarbonyl And CTAC and be dissolved in oleylamine, obtain platinum oleylamine solution; Copper acetylacetonate is dissolved in oleylamine, obtain copper oleylamine solution; Wherein the ratio of the amount of substance of platinum acetylacetonate and copper acetylacetonate is 1:(0.3 ~3);

[0020] 2. Under the protection of nitrogen, raise the temperature of the platinum oleylamine solution to 155-170°C at a heating rate of 4-8°C / min and keep it warm for 1-1.5h, then add the copper oleylamine solution drop by drop under stirring conditions, After the dropwise addition, raise the tempe...

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the mass ratio of platinum acetylacetonate, molybdenum hexacarbonyl and CTAC (cetyltrimethylammonium chloride) described in step one is 1:0.5 : 1.8. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com