Preparation method of two-dimensional Pd nano sieve rich in catalytic activity boundary

A catalytic activity, nano-sieve technology, applied in the direction of nanotechnology, electrical components, battery electrodes, etc., can solve the problems of uncontrollable size and shape, achieve superior catalytic performance, improve electrocatalytic activity, and have good electrocatalytic application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of two-dimensional Pd nanosieve: the preparation method of Pd nanosieve, specifically the following steps:

[0028] First, 250 mg of palladium acetylacetonate, 150 mg of molybdenum hexacarbonyl, 2.5 g of cetyltrimethylammonium bromide, and 2.5 g of ascorbic acid were added to a mixed solution of 600 mL of ethanol and deionized water, and stirred at room temperature for 48 h. The volume ratio of ethanol to deionized water was 5:1.

[0029] Then, the reacted solid-liquid mixture was centrifuged to obtain a black solid product. The product was washed 5 times with a mixed solution of ethanol and deionized water, the volume ratio of ethanol and deionized water was 1:1, and freeze-dried to obtain the product Pd nanosieve.

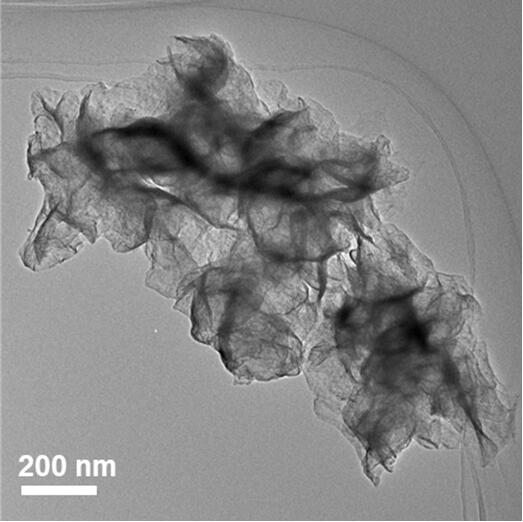

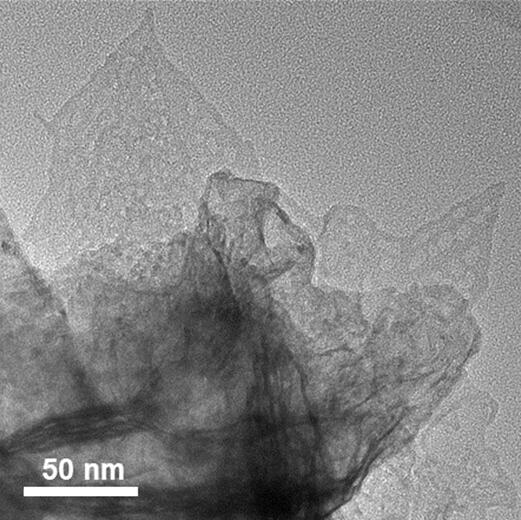

[0030] figure 1 The scanning electron microscope image of the Pd nanosieve prepared in Example 1, it can be seen from the figure that the morphology of the sample prepared in Example 1 is a nanosheet.

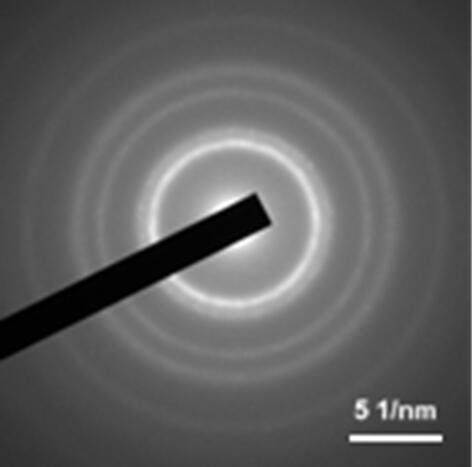

[0031] figure 2 The transmission electro...

Embodiment 2

[0037] The preparation of Pd nanosieves is specifically the following steps:

[0038] First, 20 mg of palladium acetylacetonate, 20 mg of molybdenum hexacarbonyl, 0.1 g of cetyltrimethylammonium bromide, and 0.1 g of ascorbic acid were added to a mixed solution of 30 mL of ethanol and deionized water, and stirred at room temperature for 72 h. The volume ratio of ethanol to deionized water was 5:1.

[0039] Then, the reacted solid-liquid mixture was centrifuged to obtain a black solid product. The product was washed 5 times with a mixed solution of ethanol and deionized water, the volume ratio of ethanol and deionized water was 1:1, and freeze-dried to obtain the product Pd nanosieve.

Embodiment 3

[0041] The preparation of Pd nanosieves is specifically the following steps:

[0042] First, 400 mg palladium acetylacetonate, 200 mg molybdenum hexacarbonyl, 3 g cetyltrimethylammonium bromide, and 3 g ascorbic acid were added to a mixed solution of 500 mL ethanol and deionized water, and stirred at room temperature for 72 h. The volume ratio of ethanol to deionized water was 5:1.

[0043] Then, the reacted solid-liquid mixture was centrifuged to obtain a black solid product. The product was washed 5 times with a mixed solution of ethanol and deionized water, the volume ratio of ethanol and deionized water was 1:1, and freeze-dried to obtain the product Pd nanosieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com