AB composite insulation board and insulation board assembly

A technology of composite thermal insulation and fireproof thermal insulation board, applied in the direction of thermal insulation, building components, applications, etc., can solve the problems that it is difficult to meet the requirements of external wall thermal insulation and fire protection, and it is difficult to meet the requirement of 75% energy saving, and achieve high bond strength, Good fire prevention effect and performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

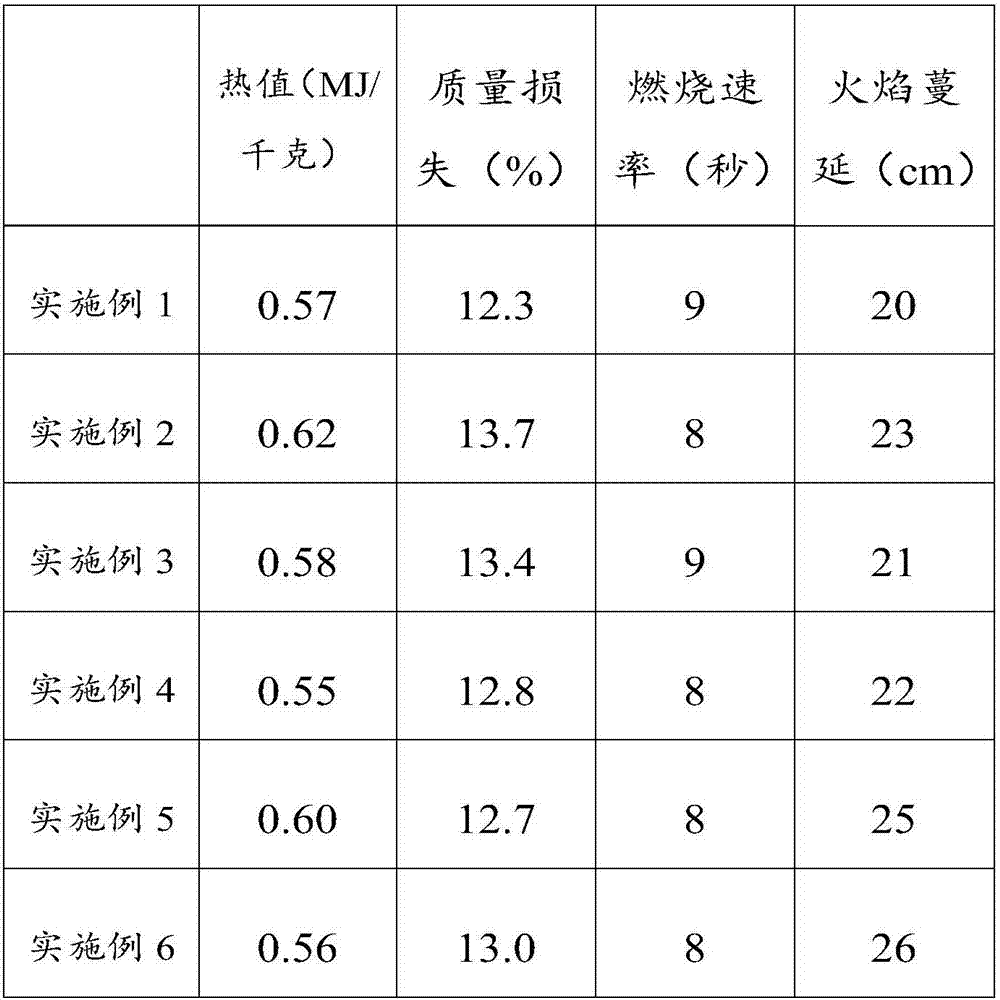

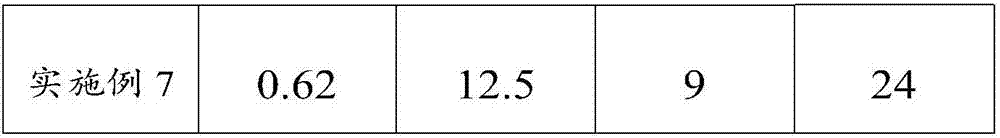

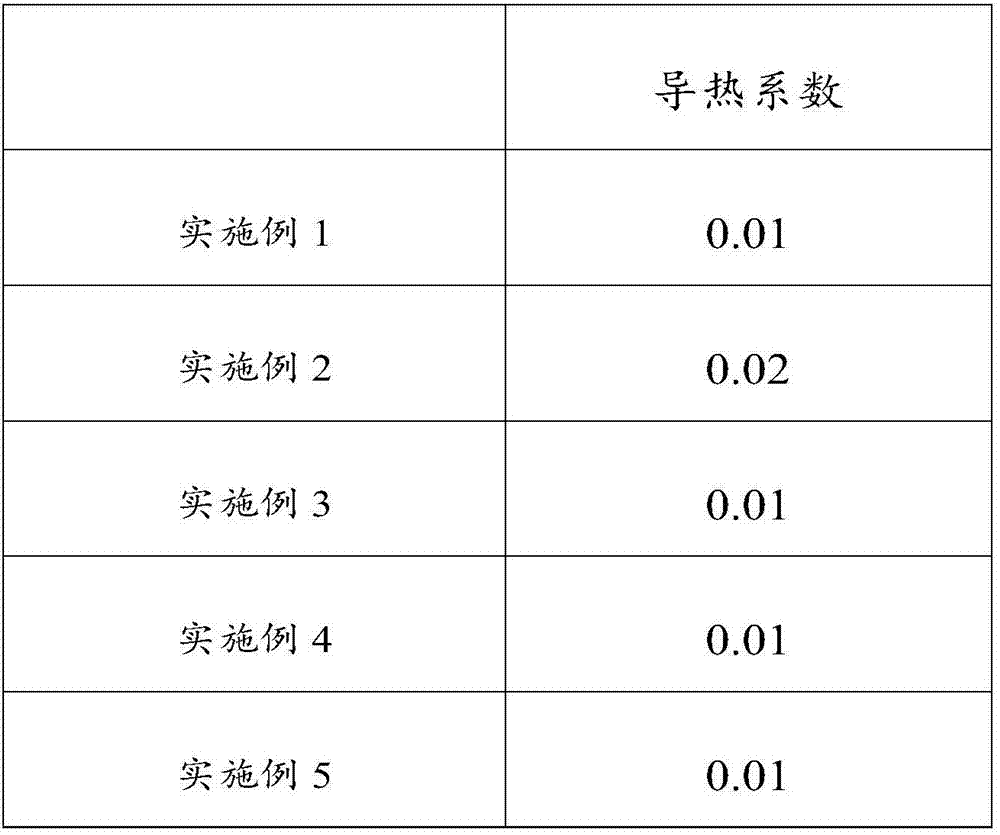

Embodiment 1

[0054] This embodiment provides an AB composite thermal insulation board, which is mainly prepared by bonding a grade A fireproof thermal insulation board and a grade B graphite polystyrene board with an adhesive. Among them, the binder is mainly prepared by mixing gelatinous material and dispersible latex powder according to the mass ratio of 20:1. Class A fireproof insulation board is mainly prepared by mixing the foamed gel material and graphene EPS at a volume ratio of 100:65.

[0055] The gelling material is mainly made of 1g of magnesium sulfate solution, 0.8g of magnesium oxide, 0.005g of sulfuric acid with a mass concentration of 28%, 0.2g of filler, 0.018g of water-resistant agent and 0.02g of modifier. Among them, the fineness of the filler is 300 mesh, and the filler is fly ash; the modifier is phosphoric acid; the magnesium oxide is light-burned magnesia, and the mass ratio of magnesium in light-burned magnesia is 90%, and its activity is 60%. ; The anti-water age...

Embodiment 2

[0067] This embodiment provides an AB composite thermal insulation board, which is mainly prepared by bonding a grade A fireproof thermal insulation board and a grade B graphite polystyrene board with an adhesive. Among them, the binder is mainly prepared by mixing gelatinous material and dispersible latex powder according to the mass ratio of 15:1. Class A fireproof insulation board is mainly prepared by mixing the foamed gel material and graphene EPS at a volume ratio of 100:85.

[0068] The gelling material is mainly made of 1g of magnesium sulfate solution, 0.85g of magnesium oxide, 0.008g of sulfuric acid with a mass concentration of 30%, 0.4g of filler, 0.015g of water-resistant agent and 0.015g of modifier. Among them, the fineness of the filler is 400 mesh, and the filler is fly ash and stone powder; the modifier is citric acid and boric acid; the magnesia is light-burned magnesia, and the mass ratio of magnesium in the light-burned magnesia is 95%, and Its activity d...

Embodiment 3

[0080] This embodiment provides an AB composite thermal insulation board, which is mainly prepared by bonding a grade A fireproof thermal insulation board and a grade B graphite polystyrene board with an adhesive. Among them, the binder is mainly prepared by mixing the gelling material and the construction glue according to the mass ratio of 25:1. Class A fireproof insulation board is mainly prepared by mixing the foamed gel material and graphene EPS at a volume ratio of 100:75.

[0081] The gelling material is mainly made of 1g of magnesium sulfate solution, 0.9g of magnesium oxide, 0.006g of sulfuric acid with a mass concentration of 29%, 0.6g of filler, 0.02g of water-resistant agent and 0.013g of modifier. Among them, the fineness of the filler is 250 mesh, and the filler is a mixture of fly ash, mineral powder and stone powder; the modifier is triethanolamine; the magnesium oxide is light-burned magnesia, and the mass ratio of magnesium in the light-burned magnesia is 85%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com