Aminoized hydroxyapatite/chitosan composite aerogel as well as preparation method and application thereof

A technology of aminated hydroxyapatite and composite airgel, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve the problem of interfacial compatibility and uniformity affecting airgel thermal insulation performance and mechanical strength , low chemical stability and mechanical strength, composite airgel brittleness and poor thermal stability, etc., to improve mechanical strength and chemical stability, avoid agglomeration and agglomeration, and improve interface affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

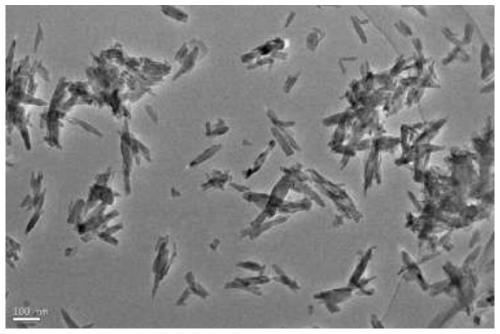

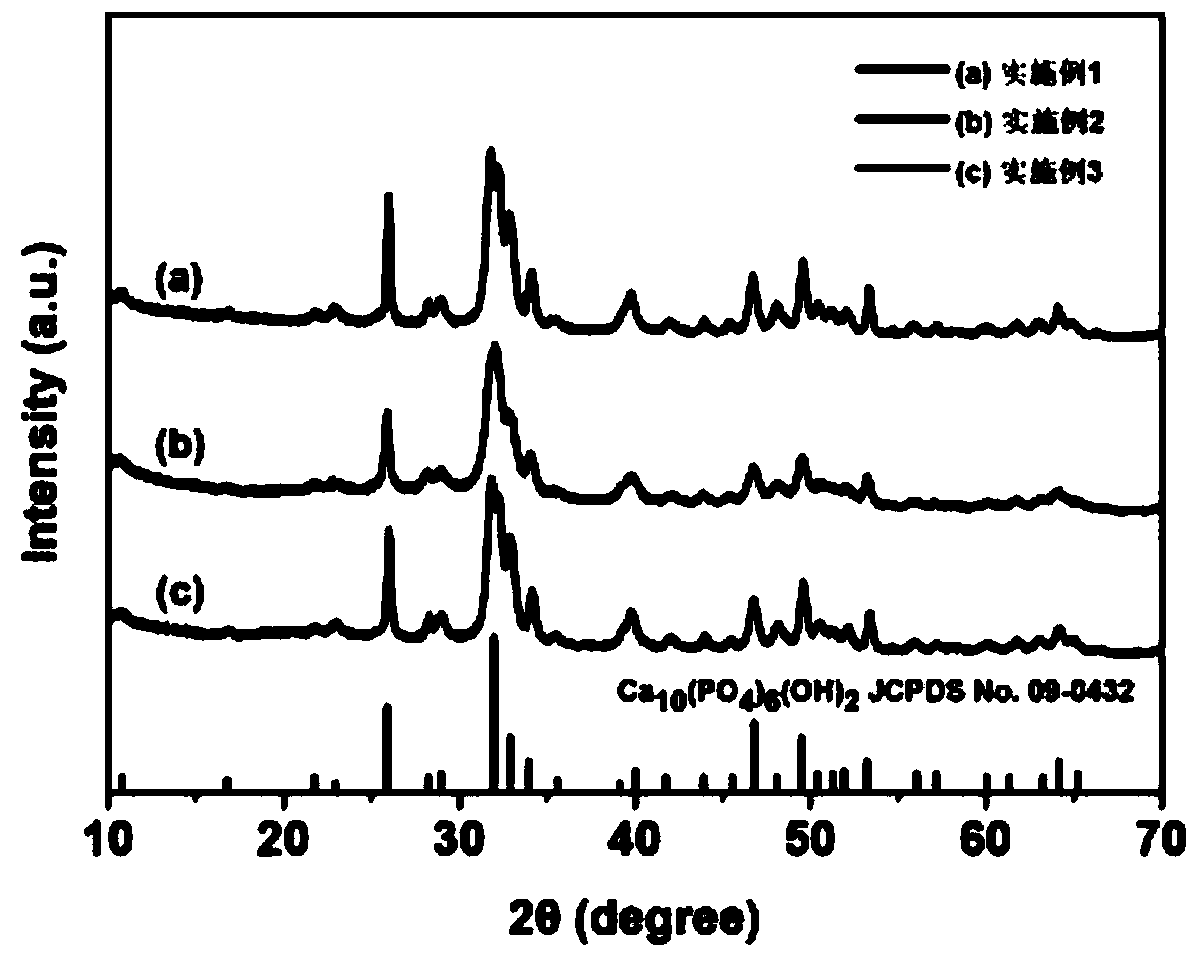

[0038] Get 4.5g of anhydrous calcium chloride (CaCl 2 ) into 500mL distilled water and stir evenly, and adjust the pH value of the solution to 11 with 1mol / L NaOH, then take 8.71g sodium dihydrogen phosphate solution (NaH 2 PO 4) was dissolved in 200mL distilled water, and stirred evenly. The sodium dihydrogen phosphate solution is slowly added dropwise to the calcium nitrate solution, and its molar ratio is Ca / P=1.67. At the same time, the pH value was adjusted to 11 with 1mol / L NaOH. After the dropwise addition was completed, the above mixture was transferred to a water bath at a temperature of 70° C. and stirred for 12 h. After the stirring was completed, the supernatant liquid was poured off by standing for stratification, washed repeatedly with distilled water and ethanol several times, the precipitated product was collected by filtration, dried at 60°C for 12 hours, and sieved with a size of 100 mesh to obtain hydroxyapatite. The scanning electron microscope image of...

Embodiment 2

[0041] 11.81g calcium nitrate [Ca(NO 3 ) 2 4H 2 O] was added to 500mL distilled water and stirred evenly, and the pH value of the solution was adjusted to 10 with ammonia water, then at a temperature of 30°C and a stirring speed of 1000rpm, 3.45g of ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) was dissolved in 200mL distilled water, and stirred evenly. The ammonium dihydrogen phosphate solution is slowly added dropwise to the calcium nitrate solution, and its molar ratio is Ca / P=1.67. At the same time, the pH value was adjusted to 10 with ammonia water. After the dropwise addition was completed, the above mixture was transferred to a water bath at a temperature of 30° C. and stirred for 18 h. After the stirring was completed, the supernatant was poured off by standing for stratification, washed repeatedly with distilled water and ethanol several times, the precipitated product was collected by filtration, dried at 60°C for 12 hours, and sieved with a size of 200 mesh t...

Embodiment 3

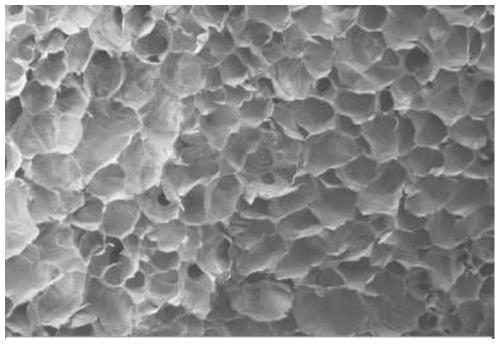

[0044] Get 4.5g of anhydrous calcium chloride (CaCl 2 ) was added to 500mL distilled water and stirred evenly, and the pH value of the solution was adjusted to 12 with 1mol / L NaOH, and then 2.48g sodium metaphosphate [(NaPO 3 ) 6 ] was dissolved in 200mL distilled water and stirred evenly. Sodium metaphosphate [(NaPO 3 ) 6 ] The solution is slowly added dropwise to the calcium chloride solution, and its molar ratio is Ca / P=1.67. At the same time, the pH value was maintained at 12 with 1mol / L NaOH. After the dropwise addition was completed, the above mixture was transferred to a water bath at a temperature of 50° C. and stirred for 6 h. After the stirring was completed, the supernatant liquid was poured off by standing for stratification, washed repeatedly with distilled water and ethanol several times, the precipitated product was collected by filtration, dried at 60°C for 12 hours, and sieved with a size of 300 mesh to obtain hydroxyapatite. The X-ray pattern of hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com