Preparation method of pure p-aramid paper

A technology of para-aramid paper and para-aramid fiber, which is applied in the field of preparation of pure para-aramid paper, and can solve problems such as unresolved concentrated sulfuric acid corrosion equipment, increased recovery of dilute sulfuric acid, and dimensional stability problems, etc. , to achieve the effect of eliminating the increased burden of sewage treatment, avoiding corrosion problems and complex problems of dilute sulfuric acid recovery, and eliminating expensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

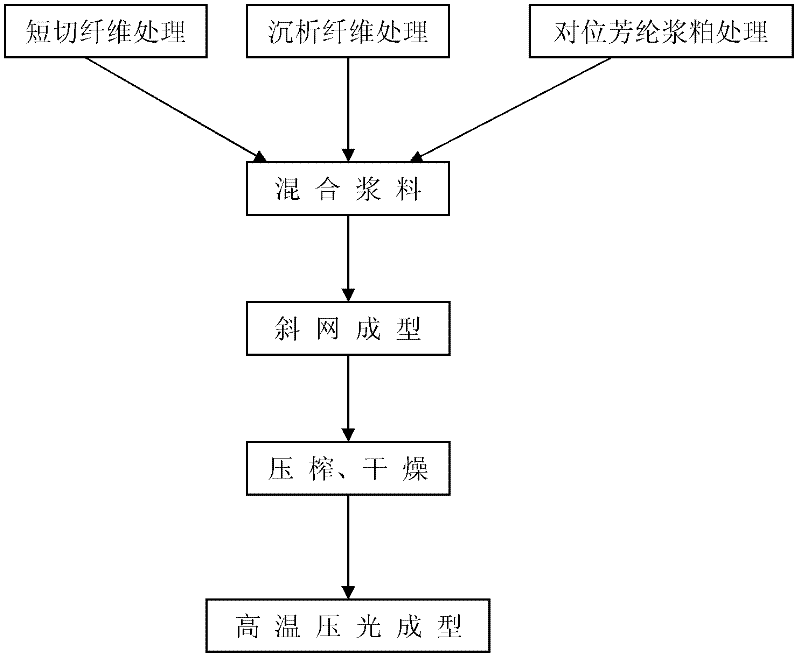

Method used

Image

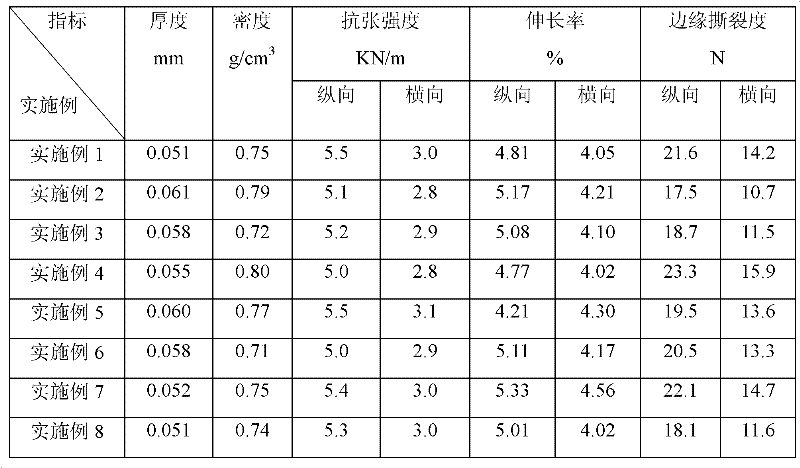

Examples

preparation example Construction

[0036] The preparation of para-aramid fibrids can adopt the following method: NMP (N-methylpyrrolidone), CaCl 2 and AlCl 3 Mix to make NMP-CaCl 2 -AlCl 3 Solvent, under the protection of nitrogen, add p-phenylenediamine to dissolve, add terephthaloyl dichloride at 5°C for pre-condensation reaction, the molar ratio of p-phenylenediamine and terephthaloyl chloride in the pre-condensation reaction is 1:0.6; pre-condensation After the reaction, add terephthaloyl chloride and stir vigorously to carry out polycondensation reaction. The molar ratio of terephthaloyl chloride added in the polycondensation reaction to p-phenylenediamine in the precondensation reaction is 1:0.4. Stop stirring when colloids are produced during the reaction. , matured at 50-80°C in a nitrogen atmosphere; the cured colloid solution and para-aramid pulp suspension enter a precipitator with a rotation speed of 1000-3000rpm for precipitation, and after precipitation, wash, beat, dehydrate and dry to obtain p...

Embodiment 1

[0044] (1) Add 0.4 parts of para-aramid chopped fibers with a length of 6 mm in 100 parts of water, and mechanically disperse the mixed solution for 10 minutes with a pulper; then add 100 parts of water and continue to disperse with a pulper for 5 minutes;

[0045] (2) Add 0.4 parts of para-aramid precipitated fibers with a beating degree of 35°SR to 40 parts of water, and use a pulper to mechanically disperse the mixed liquid for 5 minutes; then add 40 parts of water and continue to disperse with a pulper for 5 minutes ;

[0046] (3) Add 1.2 parts of para-aramid pulp with a beating degree of 55°SR to 300 parts of water, and use a pulper to mechanically disperse the mixed solution for 20 minutes; then add 300 parts of water and continue to disperse with a pulper for 5 minutes;

[0047] (4) mixing and stirring the above three kinds of slurry;

[0048] (5) Select the inclined wire forming technology of the inclined wire former, and screen the fine slurry with a pressure screen ...

Embodiment 2

[0052] (1) Add 1.0 parts of para-aramid chopped fibers with a length of 6mm in 100 parts of water, and mechanically disperse the mixed solution for 10 minutes with a pulper; then add 100 parts of water and continue to disperse with a pulper for 5 minutes;

[0053] (2) Add 3.0 parts of para-aramid precipitated fibers with a beating degree of 35°SR to 200 parts of water, and use a pulper to mechanically disperse the mixed solution for 15 minutes; then add 200 parts of water and continue to disperse with a pulper for 5 minutes ;

[0054] (3) Add 1.0 part of para-aramid pulp with a beating degree of 45°SR to 100 parts of water, and mechanically disperse the mixed solution for 20 minutes with a pulper; then add 100 parts of water and continue to disperse with a pulper for 5 minutes;

[0055] (4) mixing and stirring the above three kinds of slurry;

[0056] (5) Select the inclined wire forming technology of the inclined wire former, and screen the fine slurry with a pressure screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com