Rubber material and preparation method thereof

A rubber material, a technology of thiolated graphene, applied in the field of rubber materials, can solve the problems of difficult dispersion, limited application, poor affinity between graphene materials and rubber, etc., to improve interface affinity, reduce friction loss, and mechanical properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step: the preparation of mercaptolated graphene: 1g graphene oxide is added in the DMF of 15mL and ultrasonically makes the solution of homogeneous dispersion, adds the 2-mercaptoethylamine of 0.83g and 0.43g NaOH (the above-mentioned graphene oxide The molar ratio of the epoxy group and carboxyl group to the amino group of 2-mercaptoethylamine is about 1:1), react at 80°C for 4h; after the reaction is completed, add 1.03g EDC hydrochloride and 0.10g di Tetramethylaminopyridine (DMAP), and react at room temperature for 12h. After the reaction, the system was sunk into water, filtered, washed with deionized water repeatedly, and dried.

[0031] The second step: preparation and testing of the mercaptolated graphene-rubber composite material: the mercaptolated graphene is added to water to disperse. A certain amount of SBR latex was weighed, and added to the aqueous solution under stirring at a ratio of mercaptographene to SBR of 0.2 wt%, and stirred for 6 hours...

Embodiment 2-6

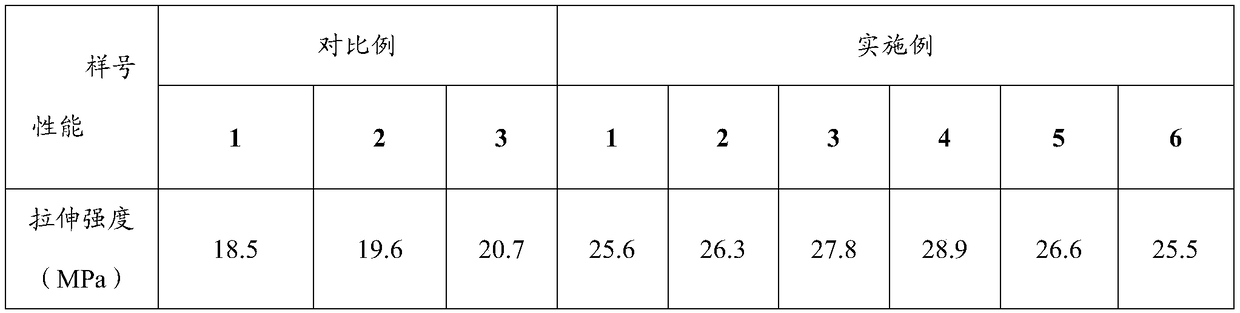

[0033] In this embodiment, the first step and the second step method are all consistent with embodiment 1, the difference is that the mass percentage of mercaptographene accounted for SBR is: 0.5wt%, 1.0wt%, 1.5wt%, 2.0wt%, 3.0 wt%, mechanical properties data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com