Method for preparing novel polyethylene wood-plastic composite material

A wood-plastic composite material and polyethylene technology, which is applied in the field of building materials, can solve the problems of polyethylene-based wood-plastic composite materials such as insufficient anti-corrosion performance, shortened service life, and performance degradation, so as to eliminate weak boundary effects and improve uniformity. Sexuality, the effect of increasing the degree of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

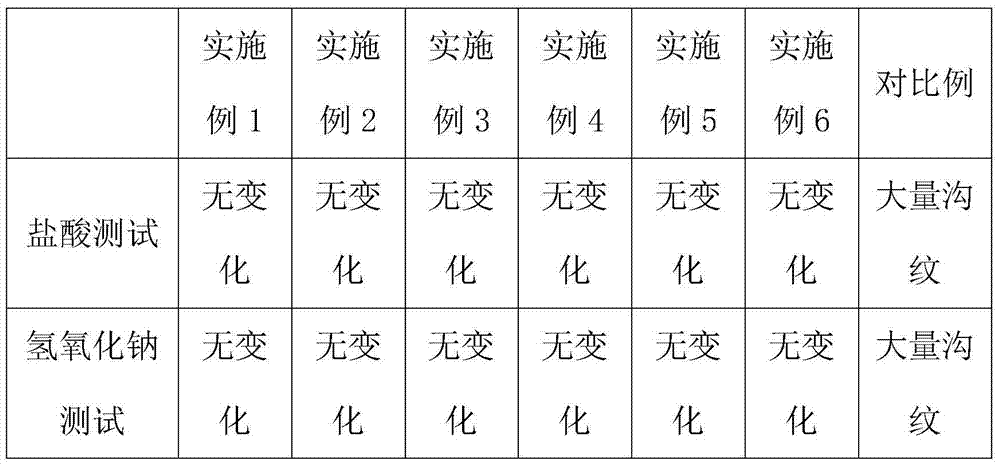

Examples

Embodiment 1

[0027] A preparation method of a novel polyethylene wood-plastic composite material, the steps are as follows:

[0028] (1) Add rapeseed straw, cotton straw and cotton straw with a weight ratio of 1:2:1 to a pulverizer for 3 hours and put them in a drying oven at 120°C for 12 hours to obtain the following wood with a water content of 5%. powder, soak the wood powder in a NaOH solution with a mass fraction of 20% and ultrasonically treat it for 40 minutes, the weight ratio of the wood powder to the NaOH solution is 1:2, take it out, wash it with deionized water, and dry it in an oven at 90°C for 20 minutes Sieve after 1 hour, and the particle size is 70-80 mesh alkalized wood flour;

[0029] (2) Put polyethylene, maleic anhydride, rare earth oxide, and DCP in a weight ratio of 100:4:1:2 into a mixer and knead at 140°C for 15 minutes, cool naturally to room temperature, and pulverize to obtain a rare earth phase Toner;

[0030] (3) Add phenolic resin and rare earth chloride wi...

Embodiment 2

[0034] A preparation method of a novel polyethylene wood-plastic composite material, the steps are as follows:

[0035] (1) Add rapeseed straw, cotton straw and cotton straw with a weight ratio of 1:2:1 to a pulverizer for 3 hours and put them in a drying oven at 120°C for 12 hours to obtain the following wood with a water content of 5%. powder, soak the wood powder in a NaOH solution with a mass fraction of 20% and ultrasonically treat it for 40 minutes, the weight ratio of the wood powder to the NaOH solution is 1:2, take it out, wash it with deionized water, and dry it in an oven at 90°C for 20 minutes Sieve after 1 hour, and the particle size is 70-80 mesh alkalized wood flour;

[0036] (2) Put polyethylene, maleic anhydride, rare earth oxide, and DCP in a weight ratio of 100:4:1:2 into a mixer and knead at 140°C for 15 minutes, cool naturally to room temperature, and pulverize to obtain a rare earth phase Toner;

[0037] (3) Add phenolic resin and rare earth chloride wi...

Embodiment 3

[0041]A preparation method of a novel polyethylene wood-plastic composite material, the steps are as follows:

[0042] (1) Add rapeseed straw, cotton straw and cotton straw with a weight ratio of 1:2:1 to a pulverizer for 3 hours and put them in a drying oven at 120°C for 12 hours to obtain the following wood with a water content of 5%. powder, soak the wood powder in a NaOH solution with a mass fraction of 20% and ultrasonically treat it for 40 minutes, the weight ratio of the wood powder to the NaOH solution is 1:2, take it out, wash it with deionized water, and dry it in an oven at 90°C for 20 minutes Sieve after 1 hour, and the particle size is 70-80 mesh alkalized wood flour;

[0043] (2) Put polyethylene, maleic anhydride, rare earth oxide, and DCP in a weight ratio of 100:4:1:2 into a mixer and knead at 140°C for 15 minutes, cool naturally to room temperature, and pulverize to obtain a rare earth phase Toner;

[0044] (3) Add phenolic resin and rare earth chloride wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com