Preparation method of semi-interpenetrating water-absorbent resin particles

A water-absorbing resin, semi-interpenetrating technology, applied in the field of oilfield chemistry, to achieve the effects of high salt resistance, good water absorption and good water absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

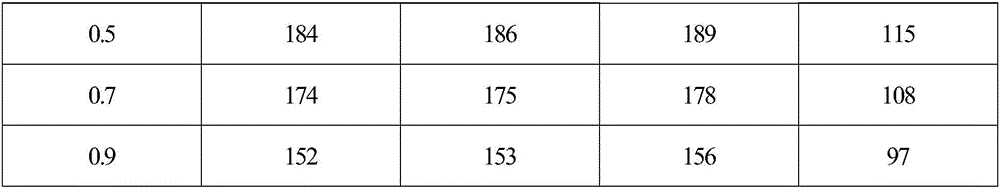

Embodiment 1

[0036] (1) Neutralize acrylic acid with 10% NaOH solution, control the neutralization degree of acrylic acid to 60% to obtain acrylic acid-sodium acrylate solution, then add dissolved acrylamide, allyl alcohol polyoxyethylene ether, polyvinyl alcohol solution to acrylic acid -Mix uniformly in sodium acrylate solution to obtain a mixed solution; wherein, the mass ratio of acrylic acid to acrylamide is 3:1, the addition of allyl alcohol polyoxyethylene ether is 4% of the total mass of acrylic acid and acrylamide, and the amount of polyvinyl alcohol The addition amount is 12% of the total mass of acrylic acid and acrylamide;

[0037](2) Add the cross-linking agent MBA to the mixed solution and stir evenly, then raise the temperature of the system to 65°C, add the initiator ammonium persulfate and stir for 15-20 minutes, then react for 2-3 hours to obtain rubber blocks; wherein, the amount of cross-linking agent It is 0.08% of the total mass of the monomer, and the addition amount...

Embodiment 2

[0040] (1) Neutralize acrylic acid with 10% NaOH solution, control the neutralization degree of acrylic acid to 90% to obtain acrylic acid-sodium acrylate solution, then add dissolved acrylamide, allyl alcohol polyoxyethylene ether, polyvinyl alcohol solution to acrylic acid -Mix uniformly in sodium acrylate solution to obtain a mixed solution; wherein, the mass ratio of acrylic acid to acrylamide is 5:1, the addition of allyl alcohol polyoxyethylene ether is 7% of the total mass of acrylic acid and acrylamide, and the amount of polyvinyl alcohol The addition amount is 14% of the total mass of acrylic acid and acrylamide;

[0041] (2) Add the cross-linking agent MBA to the mixed solution and stir evenly, then raise the temperature of the system to 65°C, add the initiator ammonium persulfate and stir for 15-20 minutes, then react for 2-3 hours to obtain rubber blocks; wherein, the amount of cross-linking agent It is 0.08% of the total mass of the monomer, and the addition amoun...

Embodiment 3

[0044] (1) Neutralize acrylic acid with 10% NaOH solution, control the neutralization degree of acrylic acid to 80% to obtain acrylic acid-sodium acrylate solution, then add dissolved acrylamide, allyl alcohol polyoxyethylene ether, polyvinyl alcohol solution to acrylic acid - Mixed uniformly in sodium acrylate solution to obtain a mixed solution; wherein, the mass ratio of acrylic acid to acrylamide is 4:1, the addition of allyl alcohol polyoxyethylene ether is 5% of the total mass of acrylic acid and acrylamide, and the amount of polyvinyl alcohol The addition amount is 12.5% of the total mass of acrylic acid and acrylamide;

[0045] (2) Add the cross-linking agent MBA to the mixed solution and stir evenly, then raise the temperature of the system to 65°C, add the initiator ammonium persulfate and stir for 15-20 minutes, then react for 2-3 hours to obtain rubber blocks; wherein, the amount of cross-linking agent It is 0.08% of the total mass of the monomer, and the additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com