Flame-retardant polypropylene material containing char-forming agent and preparation method thereof

A polypropylene, synergistic flame retardant technology, applied in the field of propylene flame retardant polymer, can solve the problem that the material cannot reach the UL-94V-0 level.

Active Publication Date: 2015-04-29

CHANGZHOU UNIV

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The oxygen index of traditional ammonium polyphosphate and pentaerythritol flame-retardant polypropylene can be as high as 30 when the addition amount is 30%, but it cannot make the flame-retardant polypropylene composite material drip-free when burning

[0004] The problem to be solved by the present invention is: simply adding ammonium polyphosphate and pentaerythritol flame-retardant polypropylene in the prior art, it is difficult to make it burn without dripping, and the material cannot reach the UL-94 V-0 level

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

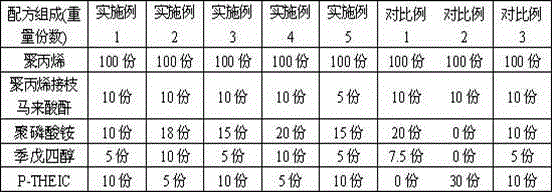

Embodiment 1-5

[0025] According to the formulation in Table 1, the components were uniformly mixed and melt-blended in an internal mixer at 190° C. and 100 rpm for 10 minutes to obtain a flame-retardant polypropylene material. The performance test results are shown in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a flame-retardant polypropylene material containing a char-forming agent and a preparation method thereof and relates to the technical field of propylene flame-retardant polymers. The flame-retardant polypropylene material comprises the following components: polypropylene, a char-forming phosphorus-nitrogen flame-retardant P-THEIC (Phosphorus-Trihydroxyethyl Isocyanurate), ammonium polyphosphate, pentaerythritol and a compatilizer. In an ammonium polyphosphate and pentaerythritol flame retardant polypropylene composite material system, the material can reach no drop during combustion and the grade UL-94 level-0 through the addition of a small quantity of P-THEIC phosphorus-nitrogen flame retardant under the situation that the addition amount of the flame retardant is not increased; as the P-THEIC is liquid under normal temperature, through the addition of the P-THEIC, the dispersity of a solid flame retardant in polypropylene can be improved, and the flowing property of the flame-retardant polypropylene material during processing can also be improved, so that molding is facilitated; as the polarity of the P-THEIC flame retardant is very small, the interface affinity is favorably improved, so that the impact strength is obviously improved.

Description

technical field [0001] The invention relates to the technical field of flame-retardant polypropylene, in particular to a flame-retardant polypropylene composite material containing a novel phosphorus-nitrogen expansion flame retardant and a preparation method thereof. Background technique [0002] Polypropylene (PP) is currently one of the resins with the largest output in the world. It is widely used in many industries such as packaging, textiles, building materials, automobiles, electronics and daily necessities. When PP is used in interior building materials, automotive interior materials, and electronic and electrical materials, because polypropylene itself is flammable and drips when burned, it is necessary to modify polypropylene flame retardant. [0003] Flame retardants used in industry are basically divided into halogen-free and halogen-containing flame retardants. Halogen-containing flame retardants are being gradually replaced by halogen-free flame retardants bec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/14C08L51/06C08K13/02C08K5/49C08K3/32C08K5/053

CPCC08L23/10C08L23/12C08L23/14C08L2201/02C08L2201/22C08L51/06C08K13/02C08K5/49C08K2003/323C08K5/053

Inventor 宋艳蒋明访李锦春张鑫邹国享

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com