Flame-retardant molybdenum disulfide modified polystyrene composite material and preparation method thereof

A molybdenum disulfide and polystyrene technology, applied in the field of polystyrene, can solve the problems of poor dispersibility of peeling molybdenum disulfide, poor flame retardancy and thermal stability of polystyrene, achieve good ligand affinity, improve application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

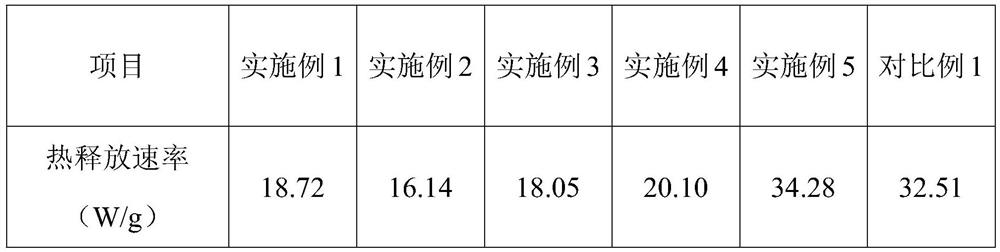

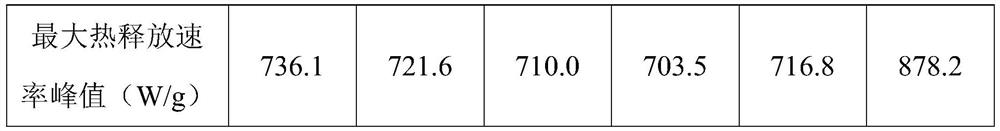

Examples

preparation example Construction

[0024] In order to achieve the above object, the present invention provides the following specific embodiments and examples: a flame-retardant molybdenum disulfide modified polystyrene composite material, the preparation method comprising the following steps:

[0025] (1) Add the n-hexane solution of n-butyllithium and nano-molybdenum disulfide to the three-necked bottle, carry out hydrothermal stripping, dry the product after cooling, and disperse it in deionized water to obtain the exfoliated molybdenum disulfide dispersion;

[0026] (2) add exfoliation molybdenum disulfide dispersion liquid and 3-mercapto-1-propylamine in the three-neck bottle, wherein the mass ratio of exfoliation molybdenum disulfide and 3-mercapto-1-propanamine is 100:110-130, in Ultrasonic stirring reaction at 15-35°C for 20-30h, the product was centrifuged, washed and dried to obtain aminated molybdenum disulfide;

[0027] (3) Add toluene, aminated molybdenum disulfide and trichloroacetyl isocyanate in...

Embodiment 1

[0031] (1) Add the n-hexane solution of n-butyllithium and nano-molybdenum disulfide to the three-necked bottle, carry out hydrothermal stripping, dry the product after cooling, and disperse it in deionized water to obtain the exfoliated molybdenum disulfide dispersion;

[0032] (2) Add exfoliated molybdenum disulfide dispersion and 3-mercapto-1-propylamine in the three-necked bottle, wherein the mass ratio of exfoliated molybdenum disulfide and 3-mercapto-1-propylamine is 100:110, at 15 ℃ Under ultrasonic stirring reaction for 20h, the product was centrifuged, washed and dried to obtain aminated molybdenum disulfide;

[0033] (3) add toluene, amidated molybdenum disulfide and trichloroacetyl isocyanate in the three-necked flask, wherein the mass ratio of amidated molybdenum disulfide and trichloroacetyl isocyanate is 100:80, transfers in the oil bath, React at 70°C for 5 hours in a nitrogen atmosphere, centrifuge, wash and dry the product to obtain trichloroacetylmolybdenum d...

Embodiment 2

[0037] (1) Add the n-hexane solution of n-butyllithium and nano-molybdenum disulfide to the three-necked bottle, carry out hydrothermal stripping, dry the product after cooling, and disperse it in deionized water to obtain the exfoliated molybdenum disulfide dispersion;

[0038] (2) Add exfoliated molybdenum disulfide dispersion and 3-mercapto-1-propylamine in the three-necked bottle, wherein the mass ratio of exfoliated molybdenum disulfide and 3-mercapto-1-propylamine is 100:115, at 20 ℃ Under ultrasonic stirring for 22 hours, the product was centrifuged, washed and dried to obtain aminated molybdenum disulfide;

[0039] (3) add toluene, amidated molybdenum disulfide and trichloroacetyl isocyanate in the three-necked flask, wherein the mass ratio of amidated molybdenum disulfide and trichloroacetyl isocyanate is 100:90, transfers in the oil bath, React at 75°C for 6 hours in a nitrogen atmosphere, centrifuge, wash and dry the product to obtain trichloroacetylmolybdenum disul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com