Environment-friendly degradable packaging composite film and preparation method thereof

A composite film, an environmentally friendly technology, applied in the field of packaging materials, can solve the problems of not being able to take into account cost and film degradation effect, mechanical properties, polymer crystallinity decrease, composite film quality degradation, etc., to achieve good mechanical properties and processability Improve and enhance the effect of water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

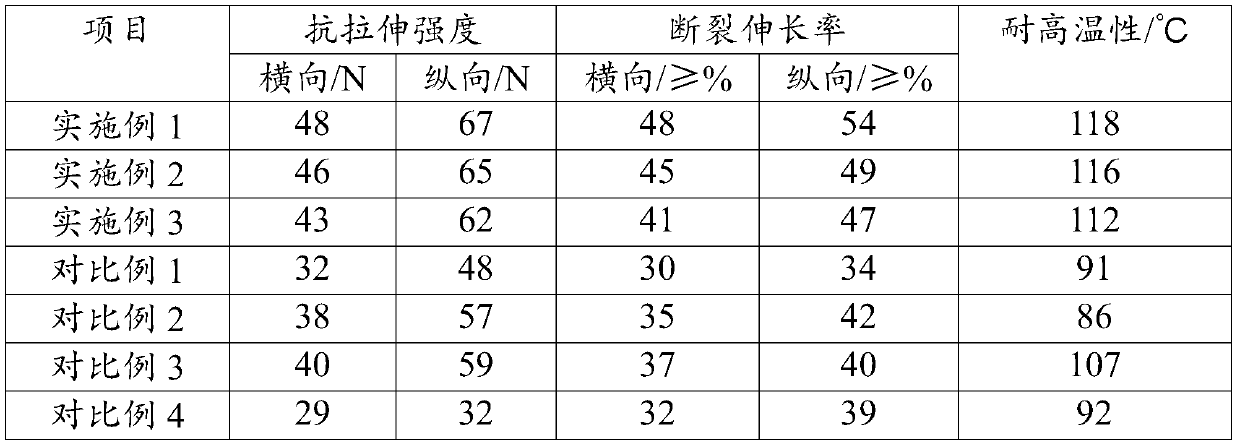

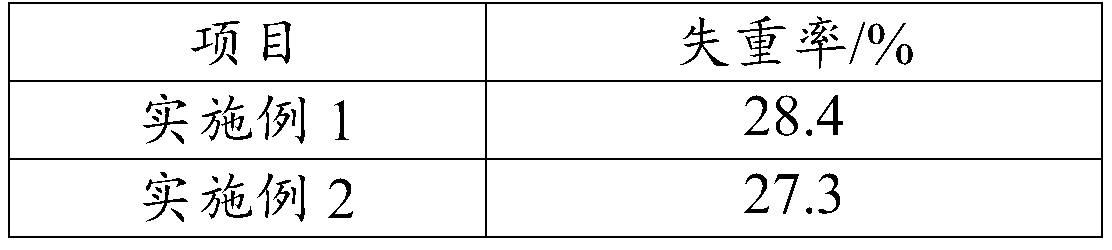

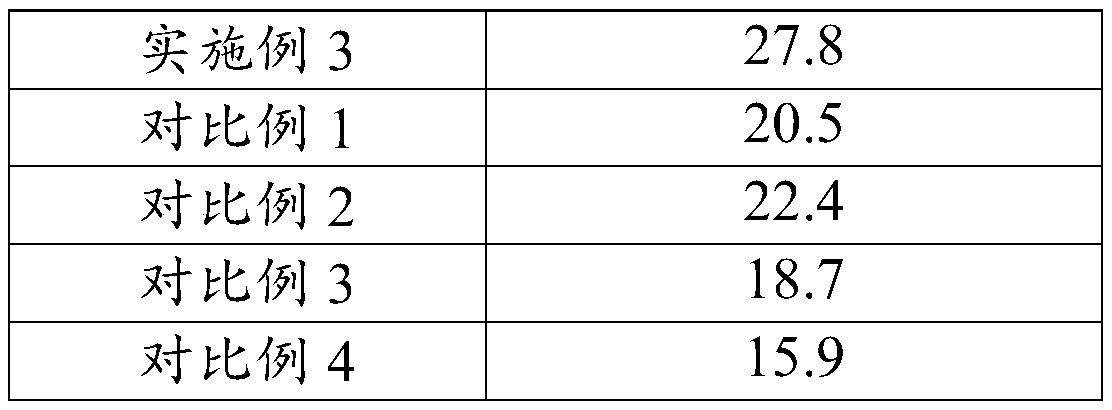

Examples

Embodiment 1

[0037] An environment-friendly degradable packaging composite film in this embodiment includes the following raw materials in parts by weight: 145 parts of modified PBS resin, 53 parts of heat-resistant modified starch, 18 parts of Biofiller828 photooxidation-biodegradation accelerator, nano-volcanic ash 14 parts, 8 parts of calcium stearate, 7 parts of nano calcium carbonate powder;

[0038] Wherein, the modified PBS resin includes the following raw materials in parts by weight: 103 parts of PBS resin, 46 parts of sago starch, 9 parts of chlorinated palm oil methyl ester, 11 parts of maleic anhydride grafted ethylene-1-octene copolymer, 4 parts of water pearlescent sand, 1.6 parts of precipitated silica; wherein, the density of the PBS resin is 1.25g / cm 3 , the melting point is 112-116°C, the heat distortion temperature is 52°C, and the Vicat softening point is 82°C; the preparation method of the modified PBS resin comprises the following steps:

[0039] 1) High-speed mixing...

Embodiment 2

[0052] An environment-friendly degradable packaging composite film of this embodiment includes the following raw materials in parts by weight: 145 parts of modified PBS resin, 53 parts of heat-resistant modified starch, 19 parts of Biofiller828 photooxidation-biodegradation accelerator, nano-volcanic ash 15 parts, 10 parts of calcium stearate, 8 parts of nano calcium carbonate powder;

[0053] Wherein, the modified PBS resin includes the following raw materials in parts by weight: 115 parts of PBS resin, 46 parts of sago starch, 10 parts of chlorinated palm oil methyl ester, 13 parts of maleic anhydride grafted ethylene-1-octene copolymer, 5 parts of water pearlescent sand, 2.5 parts of precipitated silica; wherein, the density of the PBS resin is 1.25g / cm 3 , the melting point is 112-116°C, the heat distortion temperature is 52°C, and the Vicat softening point is 82°C; the preparation method of the modified PBS resin is the same as that of Example 1.

[0054] The preparation...

Embodiment 3

[0060] An environment-friendly degradable packaging composite film of this embodiment includes the following raw materials in parts by weight: 127 parts of modified PBS resin, 56 parts of heat-resistant modified starch, 20 parts of Biofiller828 photooxidation-biodegradation accelerator, nano-volcanic ash 16 parts, 10 parts of calcium stearate, 8 parts of nano calcium carbonate powder;

[0061] Wherein, the modified PBS resin includes the following raw materials in parts by weight: 113 parts of PBS resin, 42 parts of sago starch, 10 parts of chlorinated palm oil methyl ester, 13 parts of maleic anhydride grafted ethylene-1-octene copolymer, 6 parts of water pearlescent sand, 2.5 parts of precipitated silica; wherein, the density of the PBS resin is 1.25g / cm 3 , the melting point is 112-116°C, the heat distortion temperature is 52°C, and the Vicat softening point is 82°C; the preparation method of the modified PBS resin is the same as that of Example 1.

[0062] The preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com