Preparation method of talcum powder used for ship anticorrosion coatings

An anti-corrosion coating, talc technology, applied in anti-corrosion coatings, chemical instruments and methods, fibrous fillers, etc., can solve the problems of affecting the anti-corrosion effect, irregular particle shape, physical and chemical properties, etc., to improve the anti-corrosion effect, The effect of concentrated particle size distribution and improved salt spray resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

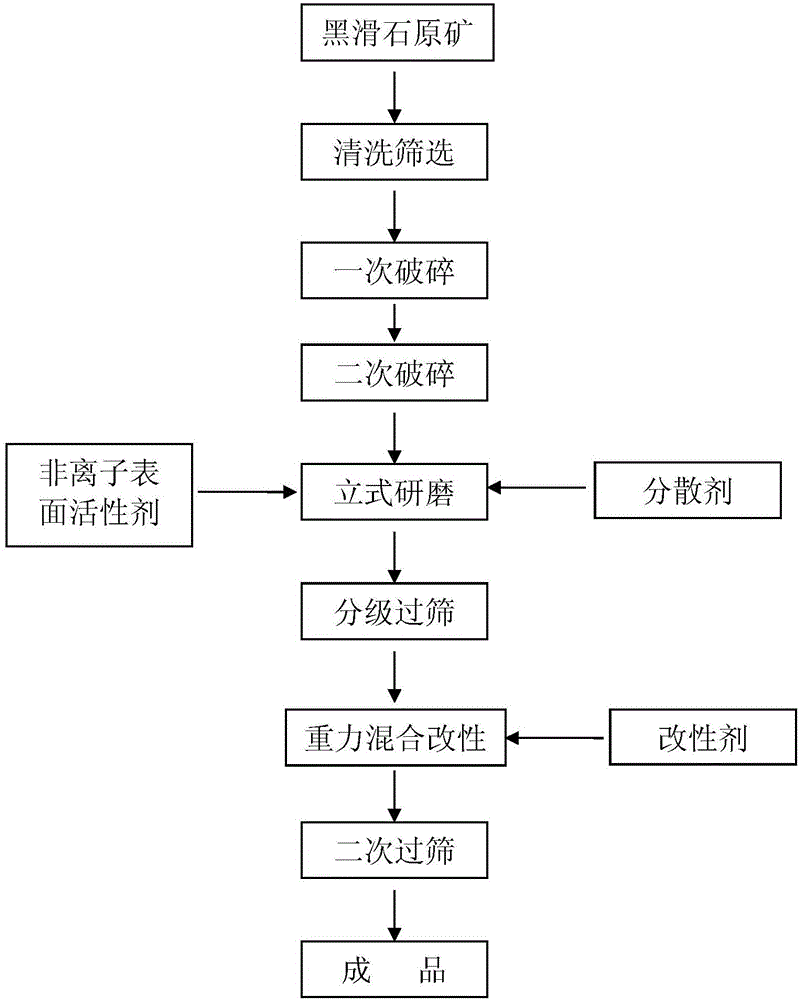

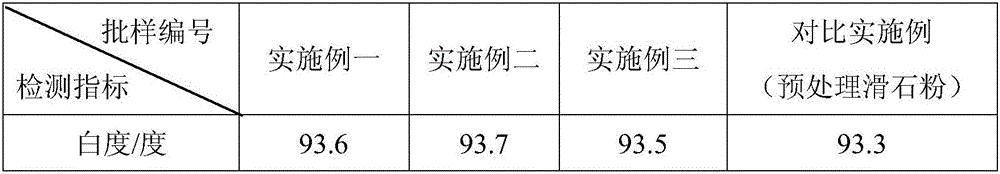

[0031] A kind of preparation method of ship anticorrosion coating talcum powder is characterized in that, comprises the following steps:

[0032] (1) Raw ore crushing: Clean the talc ore, put it into the silo for primary crushing, and crush the large raw ore into talc ore with a diameter of about 5-10cm, and then enter the secondary crushing system through the bucket elevator. It is ground into gravel with a diameter of 0.5-1cm, which meets the feeding requirements of the vertical mill;

[0033] (2) Vertical grinding: Add 1.6% alkanolamide polyoxyethylene ether and 3.5% polyacrylic acid amine salt dispersant of raw material quality to the crushed stone obtained in step (1), enter the vertical grinding equipment by conveyor belt, and grind To 3500 mesh, get pretreated talc powder; the function of non-ionic surfactant and polyacrylic acid amine salt dispersant is to improve grinding efficiency and reduce energy consumption;

[0034] (3) Grading and sieving: put the powder obtai...

Embodiment 2

[0039] A kind of preparation method of ship anticorrosion coating talcum powder is characterized in that, comprises the following steps:

[0040] (1) Raw ore crushing: Clean the talc ore, put it into the silo for primary crushing, and crush the large raw ore into talc ore with a diameter of about 5-10cm, and then enter the secondary crushing system through the bucket elevator. It is ground into gravel with a diameter of 0.5-1cm, which meets the feeding requirements of the vertical mill;

[0041] (2) Vertical grinding: Add 2.8% fatty alcohol polyoxyethylene ether of raw material quality and 2.3% polyacrylic acid amine salt dispersant to the crushed stone obtained in step (1), enter the vertical grinding equipment by the conveyor belt, and grind to 3000 To obtain pretreated talc powder; the function of nonionic surfactant and polyacrylic acid amine salt dispersant is to improve grinding efficiency and reduce energy consumption;

[0042](3) Grading and sieving: put the powder ob...

Embodiment 3

[0047] A kind of preparation method of ship anticorrosion coating talcum powder is characterized in that, comprises the following steps:

[0048] (1) Raw ore crushing: Clean the talc ore, put it into the silo for primary crushing, and crush the large raw ore into talc ore with a diameter of about 5-10cm, and then enter the secondary crushing system through the bucket elevator. It is ground into gravel with a diameter of 0.5-1cm, which meets the feeding requirements of the vertical mill;

[0049] (2) vertical grinding: in the crushed stone that step (1) obtains, add the alkanolamide polyoxyethylene ether of raw material quality 3.6%, the polyalcohol surfactant of 1.0% and the polyacrylic acid amine salt dispersant of 2.1%, Enter the vertical grinding equipment through the conveyor belt, grind to a certain degree of 2500 mesh, and obtain pretreated talc powder; the function of nonionic surfactant and polyacrylic acid amine salt dispersant is to improve the grinding efficiency an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com