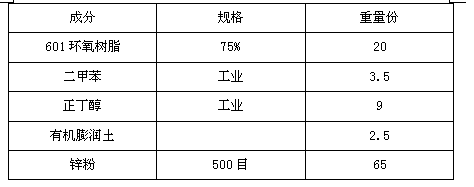

Patents

Literature

30results about How to "Increased resistance to salt spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive for bright nickel plating technology for permanent magnetic material

The invention relates to an additive for bright nickel plating technology for a permanent magnetic material. The additive comprises a primary brightening agent, a secondary brightening agent and an auxiliary additive, wherein the primary brightening agent is a compound containing an acetylenic bond or sulfonyl; sulphur in the sulfonyl is positive quadrivalent or positive hexavalent; and the secondary brightening agent is a pyridine derivative. By a combination of the pyridine derivative, a ynamine compound and a propiolic alcohol derivative and a combination of a softening agent (impurity removing agent) and a low-foam wetting agent, the novel additive for the bright nickel plating technology is prepared, and has high bright dipping speed, high dispersibility, high color and luster uniformity, fewer decomposition products, long processing cycle, high level, good ductility, high impurity tolerance, low stress and excellent electrochemical performance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

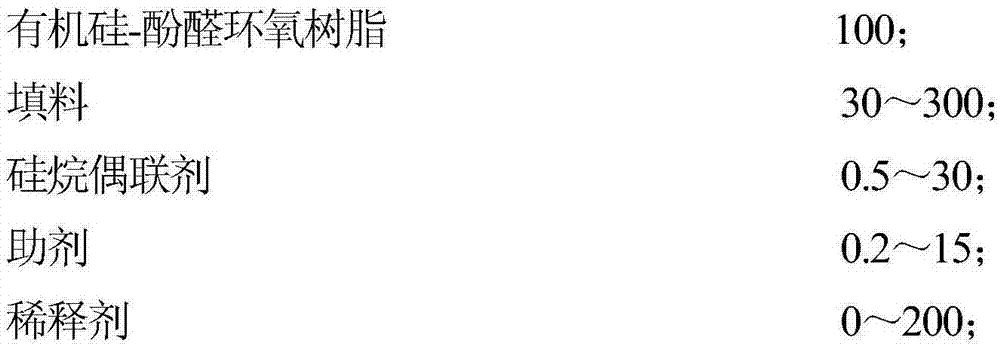

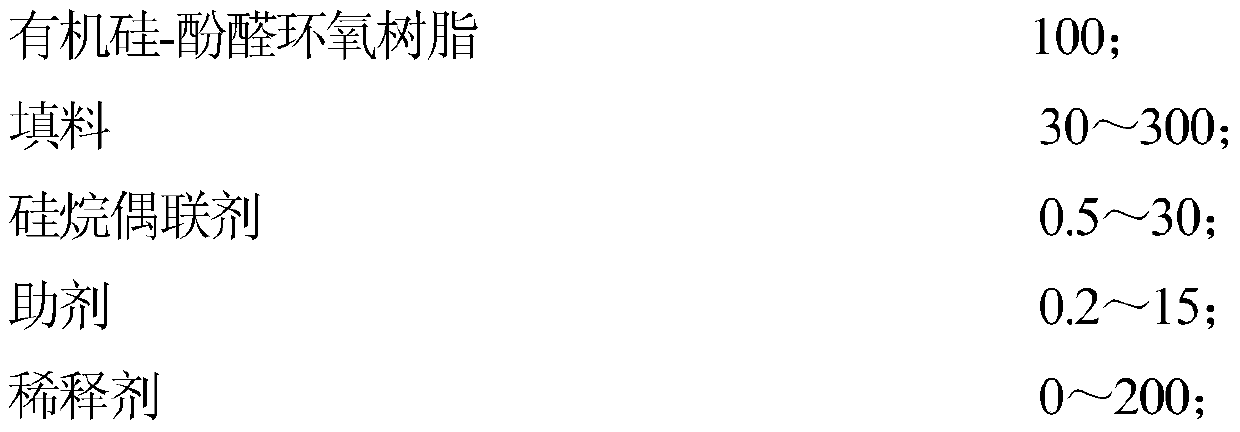

High-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and preparation method thereof

ActiveCN106893448AEasy constructionRapid ceramicizationAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

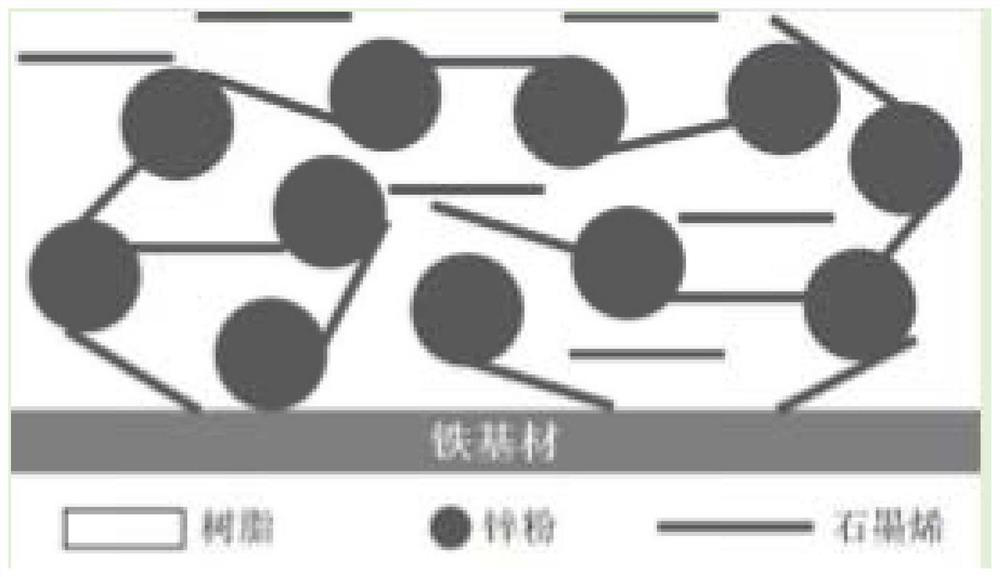

The invention belongs to the technical field of paints, and particularly relates to a high-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and a preparation method thereof. The paint is characterized in that organosilicon-phenolic epoxy resin is synthesized through a chemical grafting method, and the resin simultaneously has an organosilicon chain segment and a phenolic epoxy chain segment. On the one hand, the resin has the characteristics of heat resistance, weather resistance, wear resistance, flexibility and the like of the organosilicon chain segment, the phenolic epoxy chain segment on the resin molecule has a higher metal base material adhesive force than the organosilicon chain segment, and the corrosion resistance effect after the phenolic epoxy chain segment is crosslinked with a curing agent is higher than that of the organosilicon chain segment, thereby solving the problems of low adhesive force and poor anticorrosive effect of the organosilicon paint; and on the other hand, the carbon residue rate of the phenolic epoxy chain segment in a high-temperature environment is high, and the phenolic epoxy chain segment and a thermal degradation product of the organosilicon chain segment in the high-temperature environment can form secondary film forming action, thereby improving the ceramic effect of a coating in the high-temperature environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

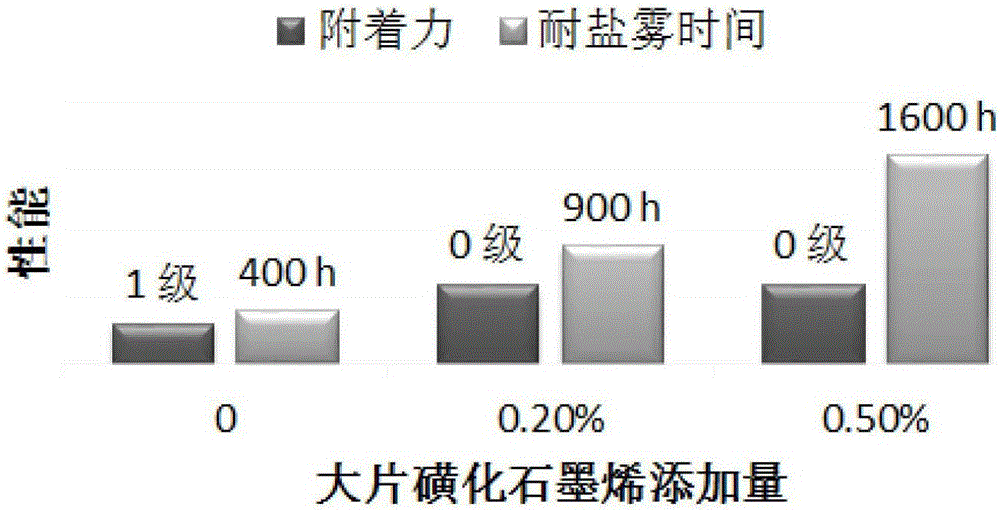

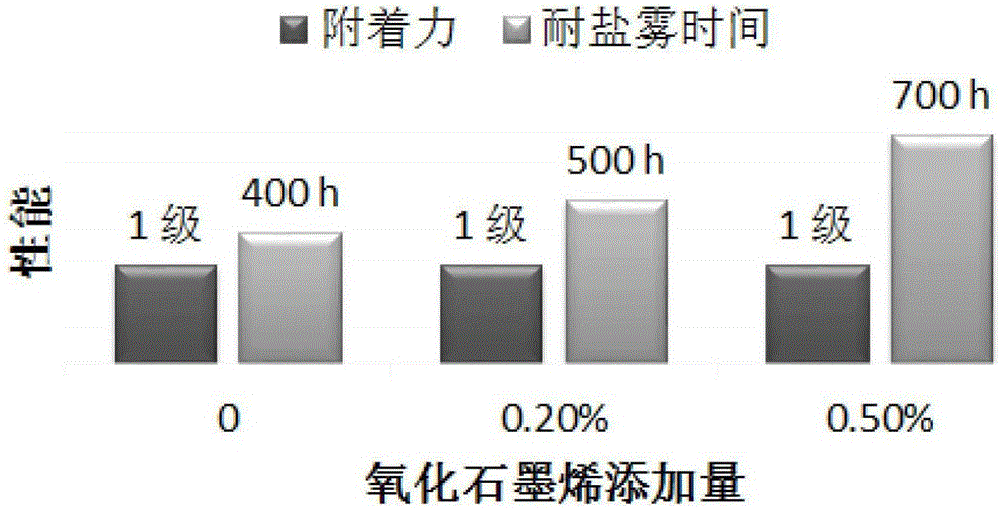

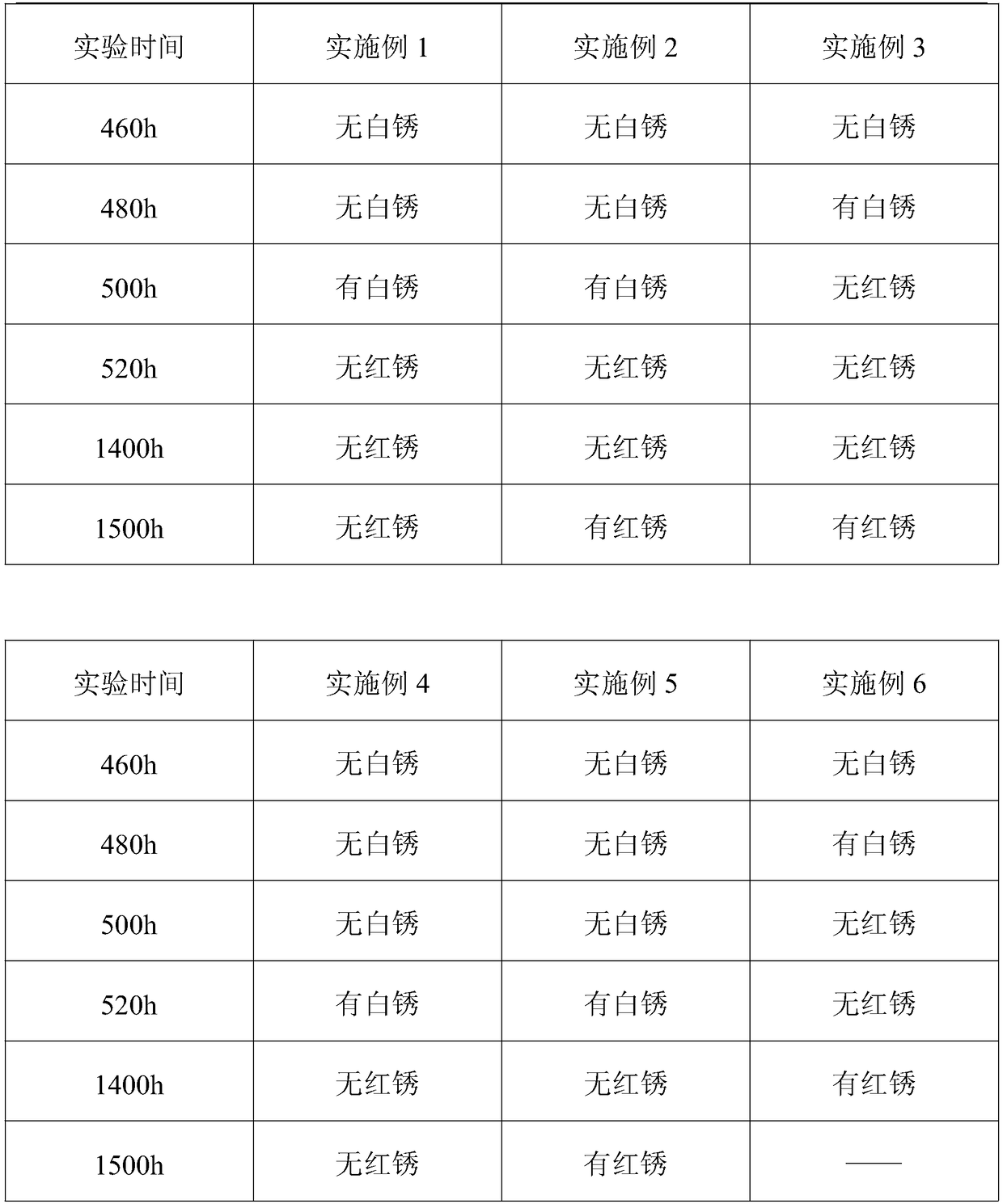

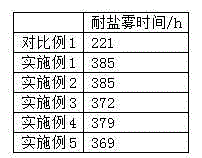

Graphene-modified water-based epoxy zinc-enriched coating as well as preparation method and application thereof

InactiveCN106634437AImprove liquidityStable storageAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphite

The invention discloses a graphene-modified water-based epoxy zinc-enriched coating as well as a preparation method and application thereof. The graphene-modified water-based epoxy zinc-enriched coating is prepared from water, a curable epoxy resin base material, a zinc powder and large-sized sulfonated graphene. The graphene-modified water-based epoxy zinc-enriched coating provided by the invention is high in flowability and can be stored stably for a long time; furthermore, a coating layer formed by the coating can be firmly combined with a base material and is excellent in corrosion resistance, flexibility, salt fog resistance and impact resistance; particularly, the fog resistance time can be prolonged by 4 times or above; the adhesion force level can reach 0, and the application prospect is wide.

Owner:SUZHOU GRAPHENE NEW MATERIAL TECH

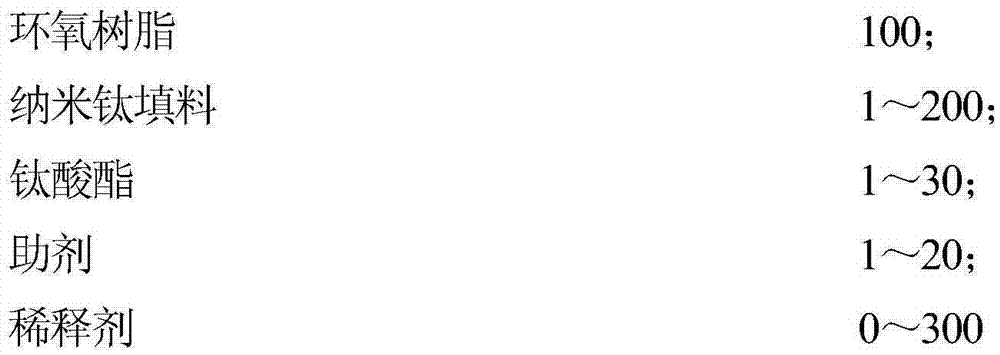

Epoxy resin-nano titanium interface chemical bonding anticorrosive coating and preparation method thereof

ActiveCN106893441ASimple production processBoth corrosion resistancePretreated surfacesAnti-corrosive paintsEpoxyWear resistant

The invention belongs to the technical field of coatings and in particular relates to an epoxy resin-nano titanium interface chemical bonding anticorrosive coating and a preparation method thereof. Firstly, a nano titanium filler grafted with epoxy resin is easily fully dissolved and wetted with coating resin, and the nano titanium filler can be uniformly dispersed in the epoxy resin of the coating and can be cross-linked with the coating resin and a curing agent together, so that the epoxy resin-nano titanium interface chemical bonding anticorrosive coating is obtained; and secondly, the metal titanium particle size of the grafted epoxy resin is in a nano scale, the grafted epoxy resin has a huge specific surface area and a good surface nano effect and can form firm interface bonding force with resin in the coating, the defects and pores of the anticorrosive coating are greatly eliminated, the phenomena such as embrittlement cracking and underfilm corrosion occurring on the anticorrosive coating are avoided, and the corrosion resistance of the coating is improved. Finally, the nano titanium filler is wear-resistant, high in strength and high in thermal stability, so that the wear resistance, mechanical properties and heat resistance of the anticorrosive coating are obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Water-based graphene zinc powder anticorrosive paint and preparation method thereof

InactiveCN114276707AEnvironmentally friendlyImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEmulsionFirming agent

The invention belongs to the field of chemical engineering, and particularly relates to a water-based graphene zinc powder anticorrosive coating, a preparation method thereof and application of the water-based graphene zinc powder anticorrosive coating in the field of corrosion resistance. The component A and the component B are mixed according to the mass ratio of (0.8-1.5): 3 when being compounded; wherein the component A comprises an epoxy resin emulsion, graphene water and an auxiliary agent, and the component B comprises a curing agent, zinc powder, a pigment filler, an auxiliary agent and a solvent. Compared with a traditional water-based graphene zinc powder coating in the market, the salt fog resistance time of the coating is greatly prolonged, specifically, the salt fog resistance time can reach 2500h or above, and corrosion at scratches spreads within 1.5 mm.

Owner:SHENYANG RES INST OF CHEM IND

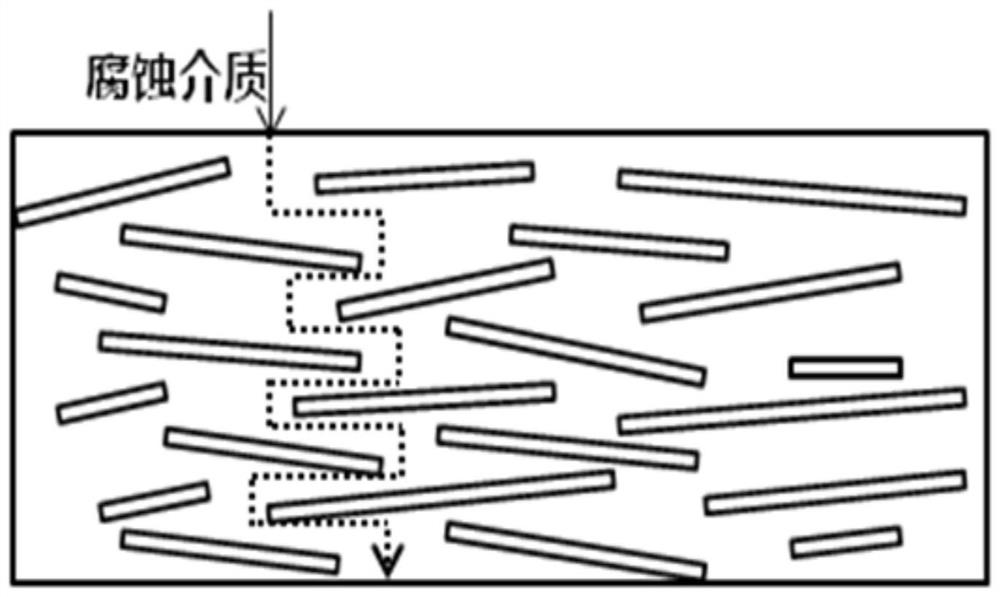

Preparation method of epoxy resin grafted montmorillonite filler

ActiveCN102532954AReduce defectsReduce porosityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPolymer science

The invention relates to a preparation method of an epoxy resin grafted montmorillonite filler. The montmorillonite filler is prepared from the following raw materials: 100 of montmorillonite, 1-45 of organic amine, protonating agent same molar equivalent with organic amine, 0.5-300 of epoxy resin, 100-10000 of dispersant, and 10-5000 of solvent. The preparation method comprises the following steps of: firstly preparing organized montmorillonite; then adding epoxy resin to the organic montmorillonite, adding the solvent to regulate the viscosity of the reaction system, reacting at the temperature range of 15-140 DEG C for 1-24 hours, introducing epoxy resin molecules to the nano laminar surface of montmorillonite, and remaining the rest epoxide group; and stripping the nano lamella of montmorillonite to obtain the epoxy resin grafted montmorillonite filler. The obtained filler has few defects and pores, and can form a densified protective layer in an anti-corrosion coating, thereby significantly improving anticorrosion effect and service life of the anti-corrosion coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Zinc-nickel alloy blue passivator and preparation method thereof

ActiveCN109252151AAvoid emissionsReduce lossesMetallic material coating processesChromium CompoundsNickel salt

The invention discloses a zinc-nickel alloy blue passivator and a preparation method thereof. The passivator comprises an agent A and an agent B, wherein the agent A comprises a trivalent chromium compound, oxalic acid, citric acid, trisodium phosphate, sodium hydroxide, a complexing agent and deionized water; the agent B comprises cobalt salt, nickel salt, sodium salt, a stabilizer and deionizedwater. The preparation method of the zinc-nickel alloy blue passivator comprises the following steps: mixing the trivalent chromium compound, oxalic acid, citric acid and trisodium phosphate with water, heating and preserving heat to obtain a trivalent chromium compound solution, dropwise adding a sodium hydroxide solution into the trivalent chromium compound solution to obtain the agent A, mixingcobalt salt, nickel salt, sodium salt and the stabilizer with water to obtain the agent B, and mixing the agent A and the agent B with water to obtain the zinc-nickel alloy blue passivator. The bluepassivator is capable of reducing loss of coating; the service life of the passivator is longer; meanwhile, the passivated appearance is better; the corrosion resistance of the coating is greatly improved.

Owner:武汉风帆电化科技股份有限公司

A kind of high-temperature ceramic silicone-phenolic epoxy anticorrosion coating and preparation method thereof

ActiveCN106893448BEasy constructionRapid ceramicizationAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

The invention belongs to the technical field of paints, and particularly relates to a high-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and a preparation method thereof. The paint is characterized in that organosilicon-phenolic epoxy resin is synthesized through a chemical grafting method, and the resin simultaneously has an organosilicon chain segment and a phenolic epoxy chain segment. On the one hand, the resin has the characteristics of heat resistance, weather resistance, wear resistance, flexibility and the like of the organosilicon chain segment, the phenolic epoxy chain segment on the resin molecule has a higher metal base material adhesive force than the organosilicon chain segment, and the corrosion resistance effect after the phenolic epoxy chain segment is crosslinked with a curing agent is higher than that of the organosilicon chain segment, thereby solving the problems of low adhesive force and poor anticorrosive effect of the organosilicon paint; and on the other hand, the carbon residue rate of the phenolic epoxy chain segment in a high-temperature environment is high, and the phenolic epoxy chain segment and a thermal degradation product of the organosilicon chain segment in the high-temperature environment can form secondary film forming action, thereby improving the ceramic effect of a coating in the high-temperature environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Salt-fog-resistant passivating agent special for galvanized steel sheet and preparation method of salt-fog-resistant passivating agent

InactiveCN104451625AIncreased resistance to salt sprayImprove salt spray resistanceMetallic material coating processesChemistryActive agent

The invention discloses a salt-fog-resistant passivating agent special for a galvanized steel sheet and a preparation method of the salt-fog-resistant passivating agent. The passivating agent comprises the following components in parts by weight: 50-80 parts of silicon dioxide, 60-100 parts of barium metaborate, 100-120 parts of polyisobutylene succinimide, 70-90 parts of sodium hydrogen phosphate, 30-80 parts of 1-hydroxyethylidene-1,1-diphosphonic acid, 20-70 parts of glycerol, 30-80 parts of an anionic surface active agent, 40-80 parts of fatty acyl diethanol amine, 30-100 parts of an auxiliary agent and 300-1000 parts of water. The preparation method comprises the following steps: adding water into a reaction kettle, sequentially adding silicon dioxide, barium metaborate, polyisobutylene succinimide, sodium hydrogen phosphate, the anionic surface active agent, fatty acyl diethanol amine and the auxiliary agent, heating to 60-70 DEG C, and stirring to react for 2-4 hours; and adding the rest components, stirring to react for 30-80 minutes, and cooling. When the passivating agent disclosed by the invention is applied to the galvanized steel sheet, the salt fog resisting time of the galvanized steel sheet can be obviously improved.

Owner:WUXI EPIC TECH

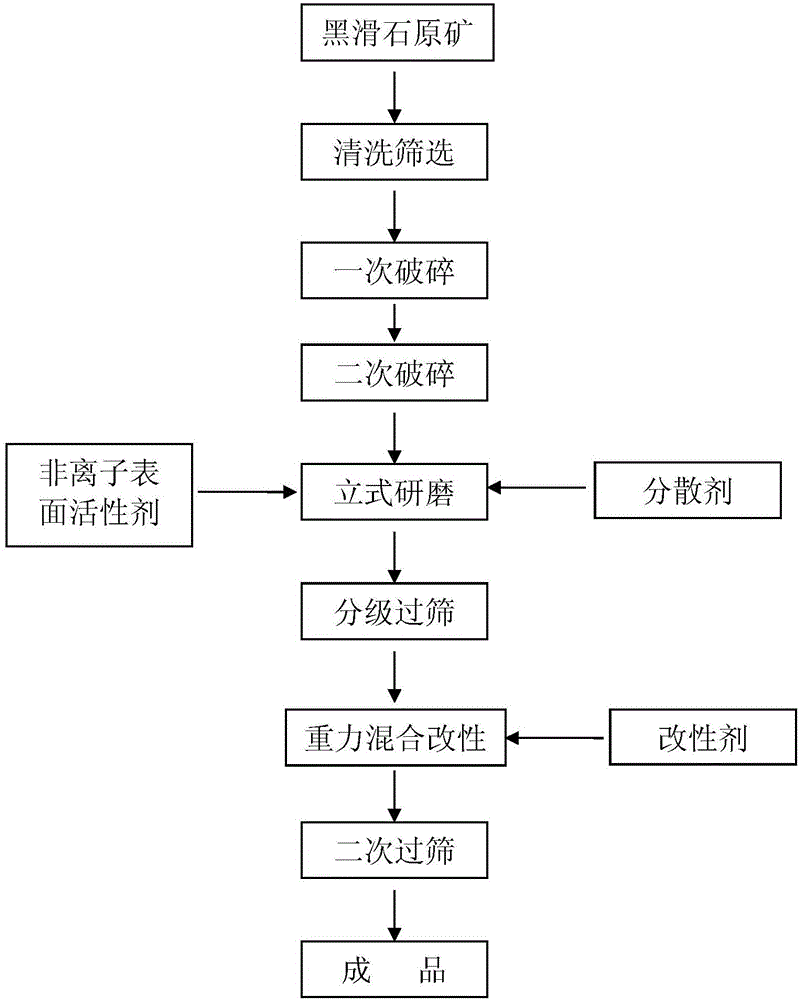

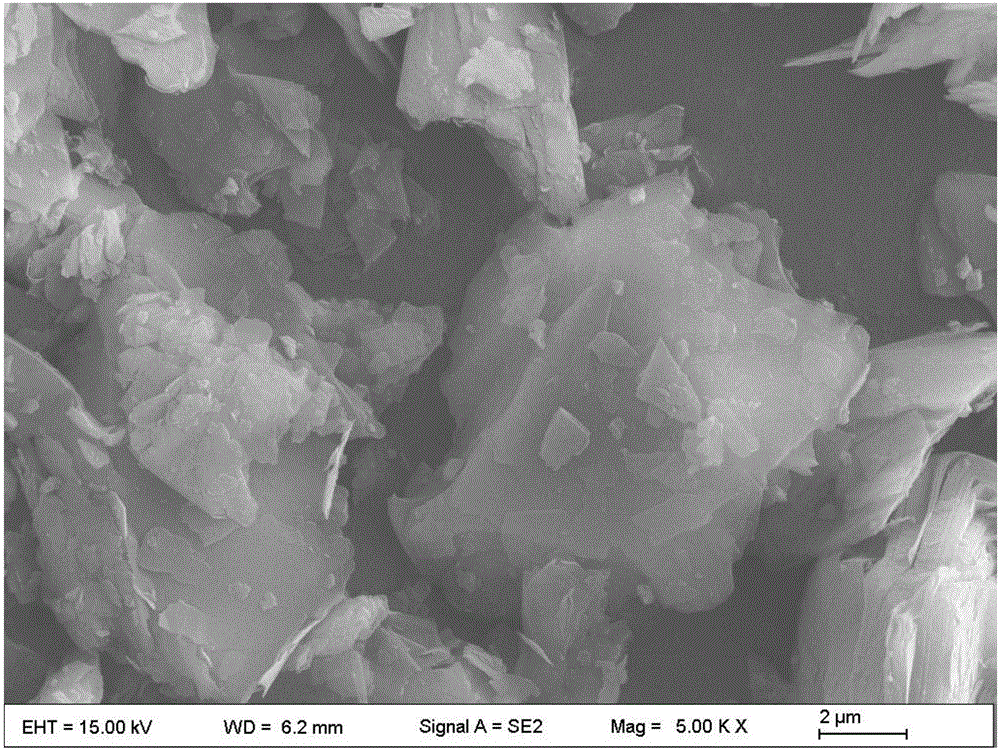

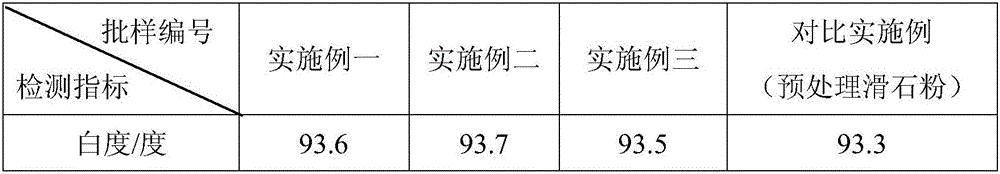

Preparation method of talcum powder used for ship anticorrosion coatings

InactiveCN106366705AImprove compactnessPrevent infiltrationAnti-corrosive paintsPigment treatment with macromolecular organic compoundsPolyethylene oxideSodium stearate

The invention provides a preparation method of talcum powder used for ship anticorrosion coatings. The method comprises the following steps: 1, crushing raw ores to form 0.5-1 cm broken stones; 2, adding a nonionic surfactant and a polyacrylamide dispersant to the broken stones, adding the obtained mixture to a vertical grinding device, and grinding the mixture to obtain preprocessed talcum powder; 3, adding the powder to a multi-stage grading system, collecting powder with the fineness of 2500-3500 meshes through a cyclone collecting system, and sieving the powder with the fineness of 2500-3500 meshes by a 300-500 mesh sieve; 4, adding the obtained powder into a gravity mixing modifier, and adding a modifier to modify the powder, wherein eh modifier includes sodium stearate, a silane coupling agent, a zirconate aluminate coupling agent, a phosphate salt coupling agent and a polyethylene oxide surfactant; and 5, carrying out secondary sieving. The talcum powder used for ship anticorrosion coatings, with the advantages of fine and unfirom granularity and complete sheet structure, is prepared through the method.

Owner:JIANGXI GUANGYUAN CHEM

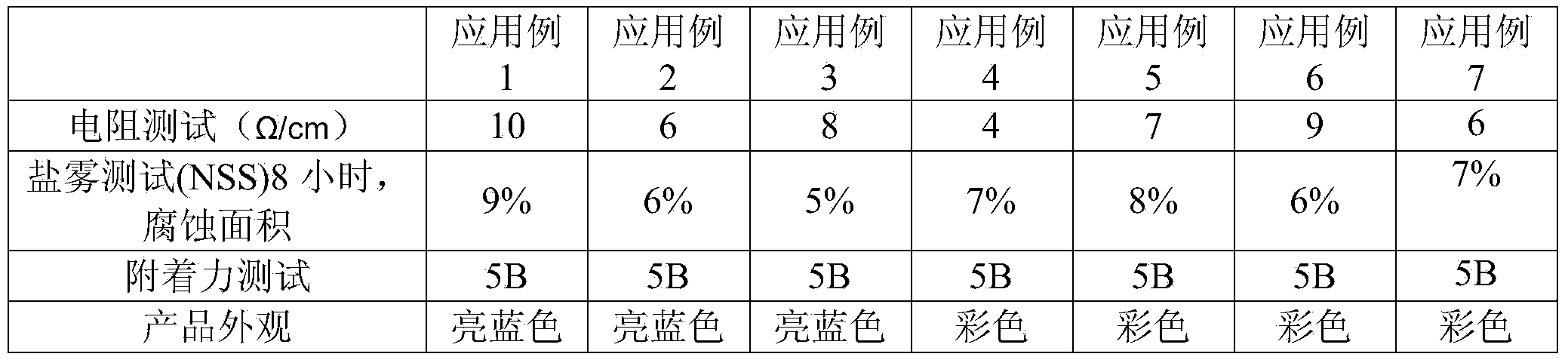

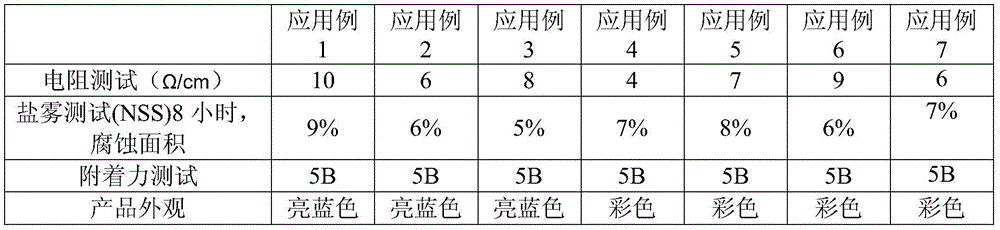

Multicolor trivalent chromium passivant for zinc coating, and preparation method and passivation treatment method thereof

ActiveCN103849867AHigh hardnessHelps against wearMetallic material coating processesSucroseToxic material

The invention provides a multicolor trivalent chromium passivant for a zinc coating, and a preparation method and a passivation treatment method thereof. The multicolor trivalent chromium passivant for the zinc coating comprises 65-75g / L of chromic anhydride, 95-110g / L of sulfuric acid, 10-20g / L of sucrose, 10-200g / L of chromic nitrate, 10-100g / L of diffusant, 20-200g / L of cobalt nitrate, 10-200g / L of hydrofluoric acid, 5-150g / L of nitric aicd, 5-150g / L of DL-tartaric acid and the balance of water. The invention provides a preparation method and an application method for the passivant. Film layers of two colors can be obtained through passivation treatment of the passivant, one is a blue film layer and the other one is a colorful film layer, the product belongs to the environmentally-friendly passivant, is free from toxic substances such as hexavalent chromium, mercury, lead, cadmium, phenlyate and the like, thus having no damage to a human body and environments.

Owner:陕西美坚默克高科技发展有限责任公司

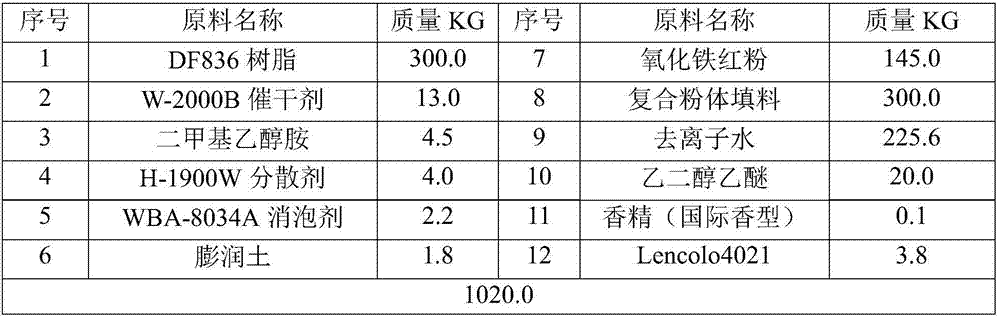

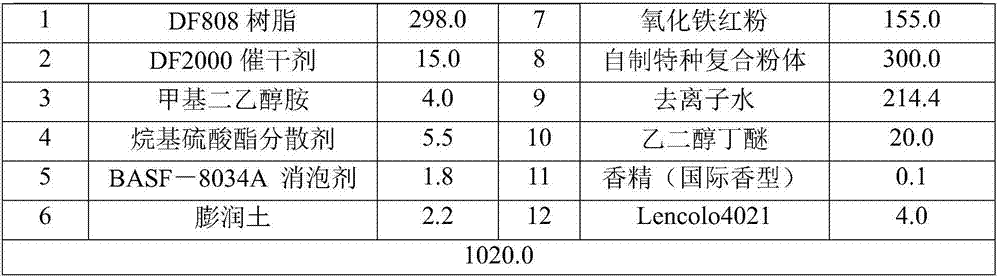

Waterborne antirust and anticorrosion paint used for iron oxide red steel structure and preparation method of waterborne antirust and anticorrosion paint

InactiveCN107474707AIncreased resistance to salt sprayImprove performanceAnti-corrosive paintsEmulsion paintsIron oxideDefoaming Agents

The invention provides waterborne antirust and anticorrosion paint which comprises the following ingredients in parts by weight: 290-310 parts of base resin, 13-17 parts of a drier, 3-6 parts of a pH regulator, 2-5 parts of a dispersing agent, 1-3 parts of a defoaming agent, 1-3 parts of a thickening agent, 140-160 parts of ferric oxide powder, 280-320 parts of compound powder filler, 2-6 parts of a salt-fog resistance additive, 15-25 parts of a membrane forming agent, 0.1-0.2 parts of essence and 220-230 parts of deionized water. Additionally, the invention also provides a preparation method of the waterborne antirust and anticorrosion paint. According to the waterborne antirust and anticorrosion paint and the preparation method thereof, waterborne alkyd resin with excellent performance is taken as a membrane forming base stock, anti-rust pigment is selected, and a compound drying technology is adopted, so that the salt-fog resistance time is greatly prolonged to 800h, and the waterborne antirust and anticorrosion paint can be completely comparable with oil paint.

Owner:广东热浪实业有限公司

Blue-white passivator of high-salt-spray-tolerance zinc coating and preparation method and passivating treatment method of blue-white passivator

InactiveCN105177557AControl film formation speedFast film formationMetallic material coating processesPotassium hydroxideSolvent

The invention provides blue-white passivator of a high-salt-spray-tolerance zinc coating and a preparation method and passivating treatment method of the blue-white passivator. According to the passivator, deionized water is adopted as a solvent, and solute comprises, by concentration, 10-20 g / L of chromic nitrate, 2.5-4 g / L of oxalic acid, 2-4 g / L of malic acid, 1.5-3 g / L of nitrilotriacetic acid, 3-5 g / L of potassium hydroxide, 2-3 g / L of cobalt nitrate, 0.5-0.8 g / L of sodium tungstate, 0.25-0.4 g / L of lanthanum nitrate and 0.4-4 g / L of gamma-aminopropyltriethoxysilane. According to the passivator, no hexavalent chromium is included in passivating liquid, and meanwhile the salt spray tolerance and corrosion resistance of a galvanized piece are improved to a large degree; meanwhile, the galvanized piece is provided with an attractive blue-white film layer, and decoration performance is improved; and the preparation method and the passivation operation process are simple, and control is easy.

Owner:武汉吉和昌新材料股份有限公司

A kind of high temperature resistant samarium cobalt permanent magnet and preparation method thereof

ActiveCN111326310BIncreased resistance to salt sprayImprove heat resistancePermanent magnetsTransformers/inductances corrosion protectionCopper platingCopper coating

Owner:上海景瑞阳实业有限公司

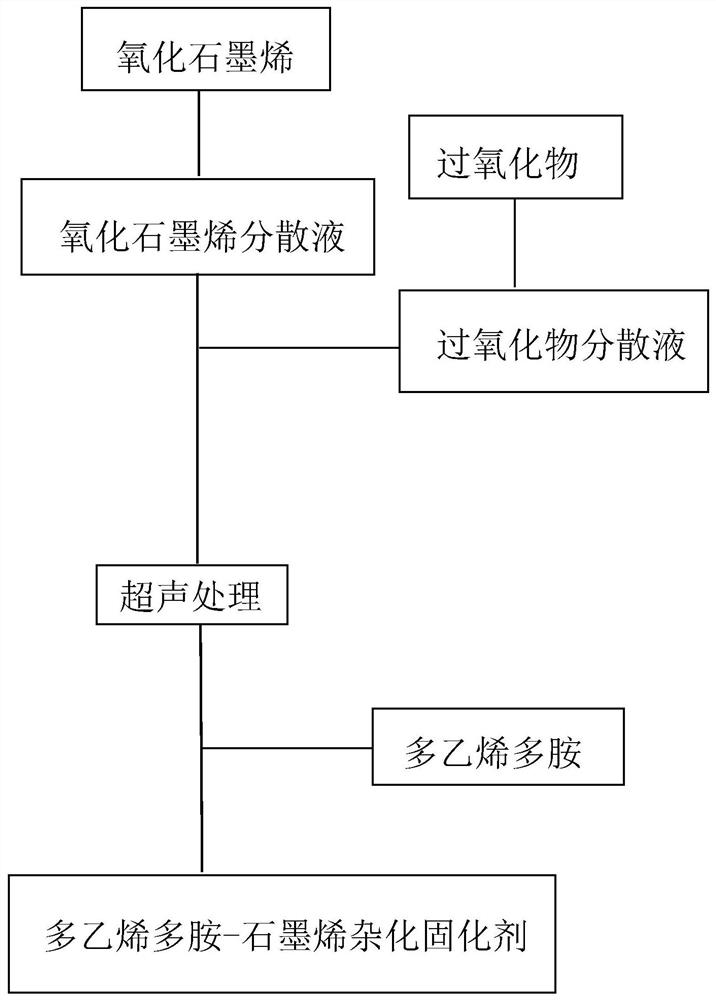

A kind of polyethylene polyamine-graphene hybrid curing agent and its preparation method and application method

ActiveCN108976890BSimple processGood storage stabilityAnti-corrosive paintsEpoxy resin coatingsFirming agentBis epoxide

A kind of polyvinylpolyamine-graphene hybrid curing agent and preparation method and application method thereof, the curing agent comprises the following components by weight: 100 parts of graphene oxide, 1-300 parts of peroxide, 1-300 parts of dispersant 5000 parts and 1-200 parts of polyethylene polyamine, firstly dispersing graphene oxide in a dispersing agent to prepare a graphene oxide dispersion liquid, simultaneously preparing a peroxide dispersion liquid in a peroxide dispersing agent, then dispersing the peroxide The dispersion is added dropwise to the graphene oxide dispersion liquid, ultrasonically treated, then polyvinylpolyamine is added, the reaction product is repeatedly washed with a dispersant, and free compounds are removed to obtain polyvinylpolyamine-graphene hybrid curing agent, which is added It is mixed into epoxy resin, mixed evenly and configured into anti-corrosion coating, which is coated on the surface of metal substrate to prepare anti-corrosion coating. The curing agent of the invention is simple to prepare, has mild reaction conditions, can improve the anti-corrosion performance of the coating, and can also be used for curing the epoxy coating.

Owner:中国人民解放军92228部队

A kind of blue-white passivator of high salt spray resistance galvanized layer and its preparation method and passivation treatment method

InactiveCN105177557BControl film formation speedFast film formationMetallic material coating processesOXALIC ACID DIHYDRATEPotassium hydroxide

Owner:武汉吉和昌新材料股份有限公司

A kind of epoxy resin-nano-titanium interface chemically bonded anticorrosion coating and preparation method thereof

ActiveCN106893441BSimple production processBoth corrosion resistancePretreated surfacesAnti-corrosive paintsPolymer scienceFirming agent

The invention belongs to the technical field of coatings and in particular relates to an epoxy resin-nano titanium interface chemical bonding anticorrosive coating and a preparation method thereof. Firstly, a nano titanium filler grafted with epoxy resin is easily fully dissolved and wetted with coating resin, and the nano titanium filler can be uniformly dispersed in the epoxy resin of the coating and can be cross-linked with the coating resin and a curing agent together, so that the epoxy resin-nano titanium interface chemical bonding anticorrosive coating is obtained; and secondly, the metal titanium particle size of the grafted epoxy resin is in a nano scale, the grafted epoxy resin has a huge specific surface area and a good surface nano effect and can form firm interface bonding force with resin in the coating, the defects and pores of the anticorrosive coating are greatly eliminated, the phenomena such as embrittlement cracking and underfilm corrosion occurring on the anticorrosive coating are avoided, and the corrosion resistance of the coating is improved. Finally, the nano titanium filler is wear-resistant, high in strength and high in thermal stability, so that the wear resistance, mechanical properties and heat resistance of the anticorrosive coating are obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Additive for bright nickel plating technology for permanent magnetic material

The invention relates to an additive for bright nickel plating technology for a permanent magnetic material. The additive comprises a primary brightening agent, a secondary brightening agent and an auxiliary additive, wherein the primary brightening agent is a compound containing an acetylenic bond or sulfonyl; sulphur in the sulfonyl is positive quadrivalent or positive hexavalent; and the secondary brightening agent is a pyridine derivative. By a combination of the pyridine derivative, a ynamine compound and a propiolic alcohol derivative and a combination of a softening agent (impurity removing agent) and a low-foam wetting agent, the novel additive for the bright nickel plating technology is prepared, and has high bright dipping speed, high dispersibility, high color and luster uniformity, fewer decomposition products, long processing cycle, high level, good ductility, high impurity tolerance, low stress and excellent electrochemical performance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

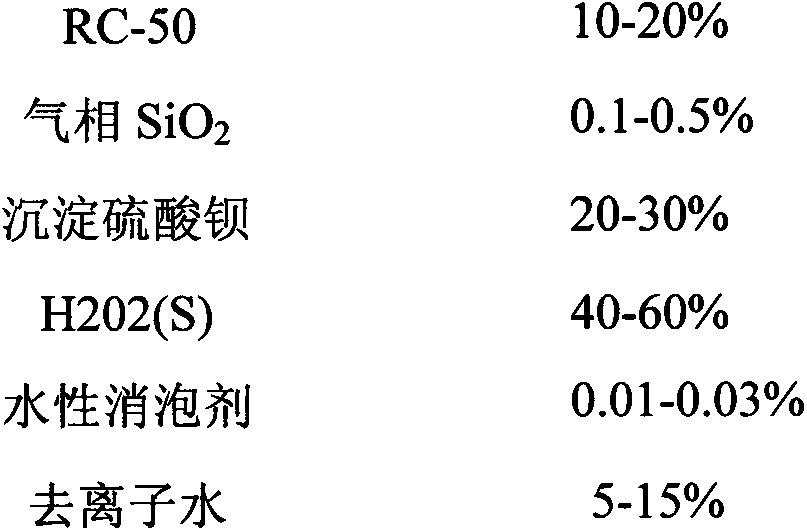

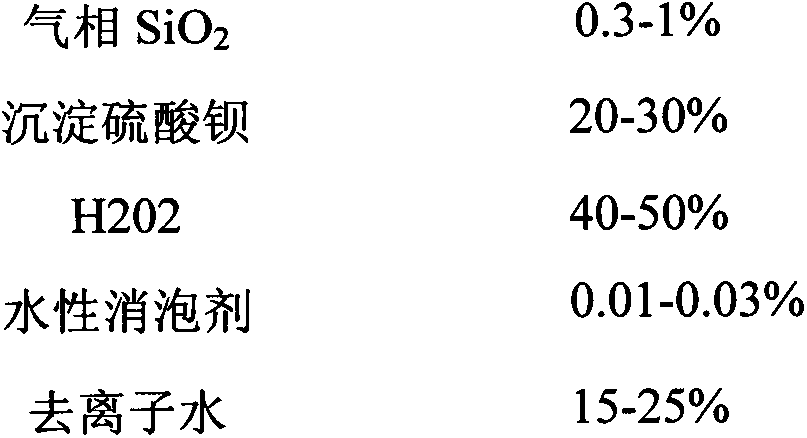

Rust transfer agent and preparation method thereof

InactiveCN104119719AHigh resistance to salt sprayIncreased resistance to salt sprayAnti-corrosive paintsSand blastingDefoaming Agents

The invention discloses a rust transfer agent. The rust transfer agent is prepared from the following raw materials in percentage by weight: 10-20% of RC-50, 0.1-0.5% of gaseous SiO2, 20-30% of precipitated barium sulphate, 40-60% of H2O2 (S), 0.01-0.03% of waterborne defoaming agent and 5-15% of deionized water, or 8-18% of RC-50, 0.3-1% of gaseous SiO2, 20-30% of precipitated barium sulphate, 40-50% of H2O2, 0.01-0.03% of waterborne defoaming agent and 15-25% of deionized water. The preparation method comprises the following steps of firstly, adding the metered deionized water, RC-50 and H2O2 (S) into a vessel, and uniformly stirring by using a high-speed dispersion machine; adding the waterborne defoaming agent, and uniformly stirring; and adding gaseous SiO2 and precipitated barium sulphate, and uniformly stirring to obtain the waterborne rust transfer agent. The rust transfer agent is favorable in rust removal and prevention performances, good in film forming property, environment-friendly, simple in construction process and low in cost; and in addition, the rust transfer agent can be formed into an inert metal complex together with metal oxide and can form a protective layer on the surface of metal, so that the salt spray resistance property of a product is greatly improved. The rust transfer agent can be used for replacing pickling, sand blasting and a manual method to remove rust and is environment-friendly, nontoxic, harmless, free of pollution and convenient to use.

Owner:TIANJIN FATONG TECH

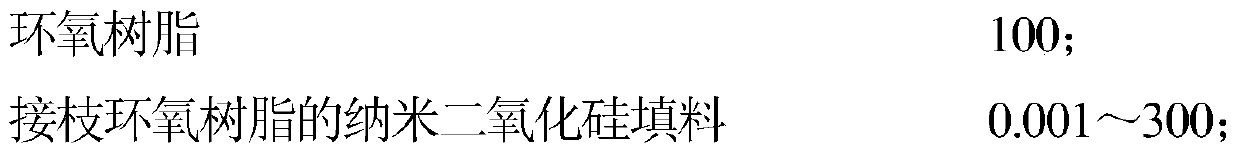

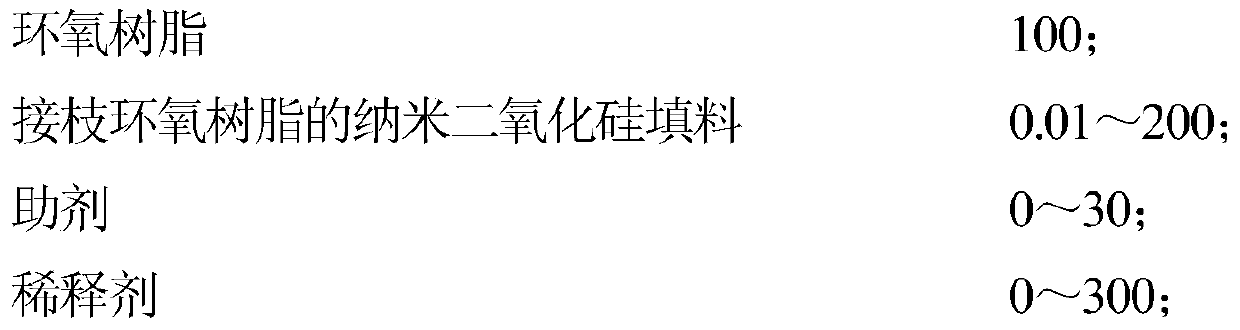

A kind of transparent nano silicon dioxide-epoxy resin anticorrosion coating and preparation method thereof

ActiveCN106893442BAccelerated corrosionImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilica particle

The invention belongs to the technical field of paint, and particularly relates to a transparent nano silicon dioxide-epoxy resin anticorrosive paint and a preparation method thereof. Firstly, the dispersion size of the nano silicon dioxide in the coating is much smaller than the wavelength of visible light; and therefore, the coating formed by applying and curing the paint has favorable transparency, and people can clearly observe the shape, size, color and other properties of the object under the coating through the coating. Secondly, the epoxy-resin-grafted nano silicon dioxide filler can be sufficiently dissolved and wetted by the paint resin easily; especially, the particle size of the epoxy-resin-grafted silicon dioxide is nano-sized, so the epoxy-resin-grafted silicon dioxide has huge specific area and surface nano effect and can form firm interface binding force with the resin in the coating, thereby greatly eliminating the defects and pores in the anticorrosive coating, inhibiting the anticorrosive coating from embrittlement-caused cracking, underfilm corrosion and the like, and further obviously enhancing the corrosion-resistant effect and service life of the anticorrosive coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

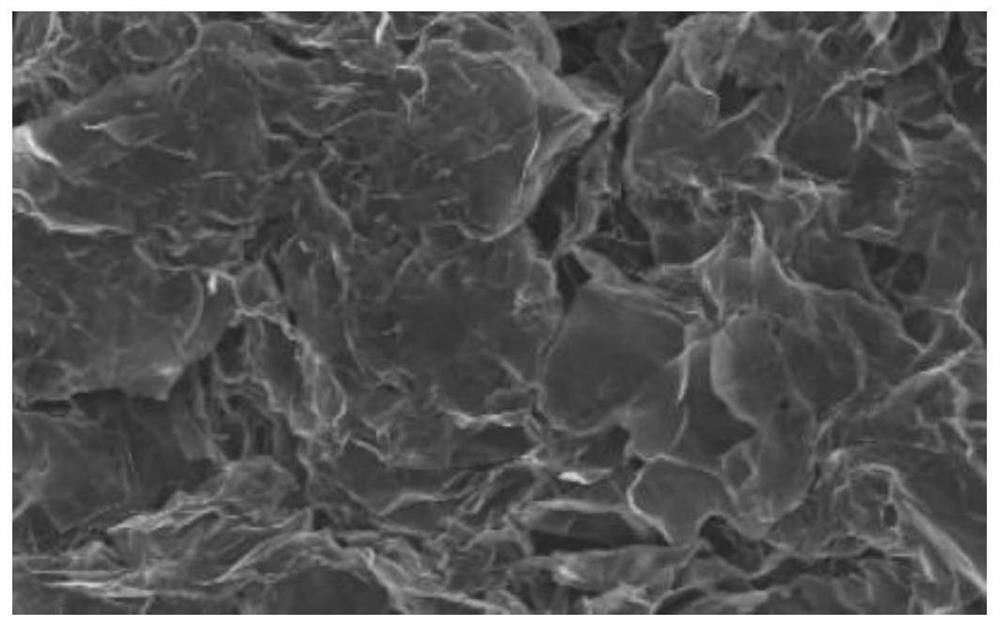

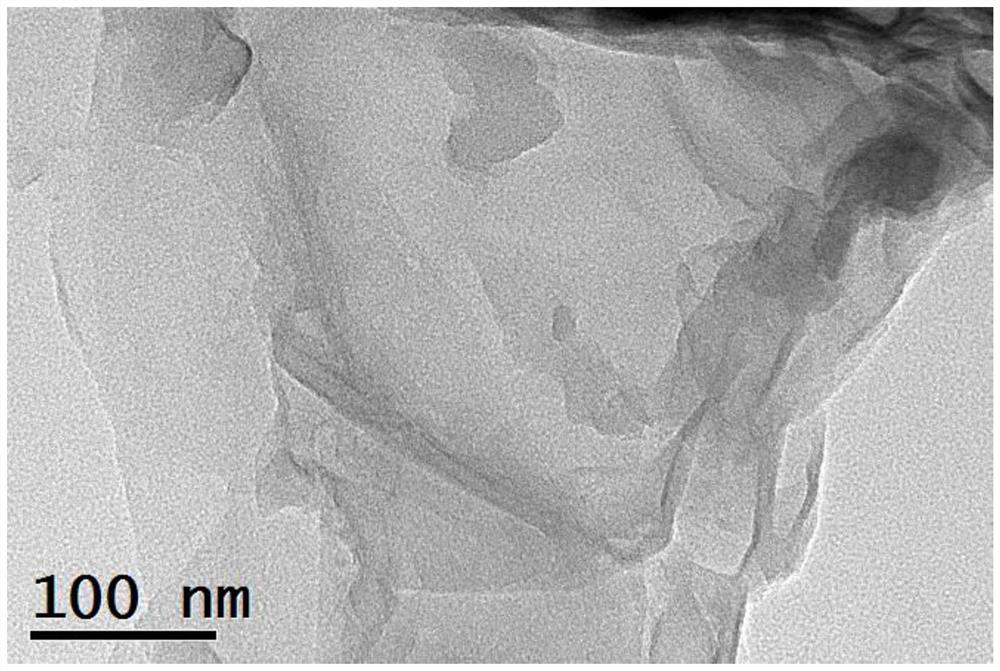

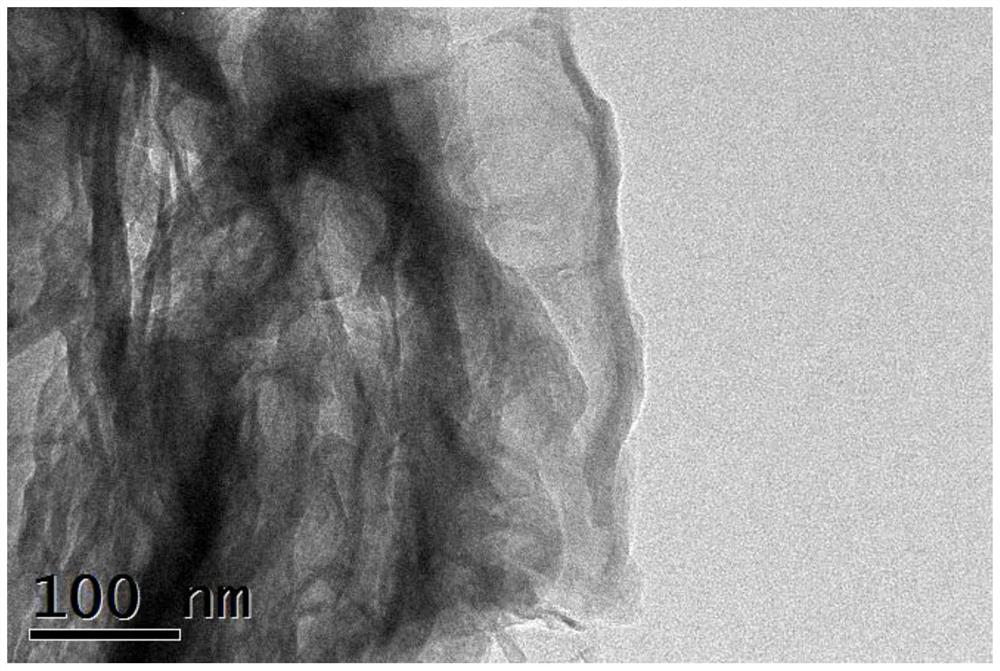

A kind of epoxy resin-graphene interface chemical bonding anticorrosion coating and preparation method

ActiveCN106893447BImprove mechanical propertiesImprove conductivityAnti-corrosive paintsEpoxy resin coatingsCross-linkEpoxy

The invention belongs to the technical field of coatings and in particular relates to an epoxy resin-graphene interface chemical bonding anticorrosive coating and a preparation method thereof. In the anticorrosive coating, graphene grafted with epoxy resin is added to serve as filler, and the filler is prepared through a peroxide treatment technology. The epoxy resin grafted to the surface of the graphene has high compatibility with epoxy resin in the coating, can be uniformly dispersed in the epoxy resin in the coating, and carries out a cross-linking reaction with a curing agent so as to obtain the epoxy resin-graphene interface chemical bonding anticorrosive coating. The coating disclosed by the invention is wide and readily available in raw materials, can be produced on general coating manufacturing equipment and can be coated by multiple methods such as brushing, spraying and dipping, and the coating layer obtained after coating curing has the characteristics of corrosion resistance, high strength, high conductivity and the like. The anticorrosive coating obtained after coating curing can be independently used and can also be matched with corresponding intermediate coat or finishing coat.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

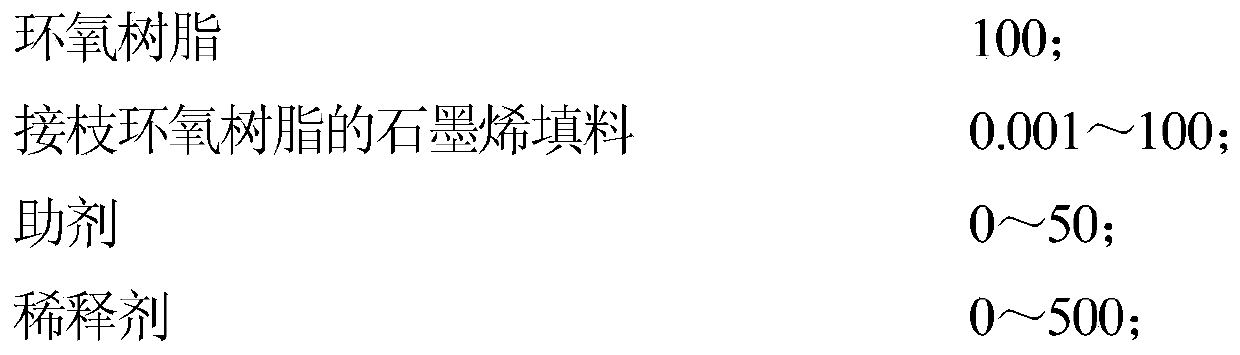

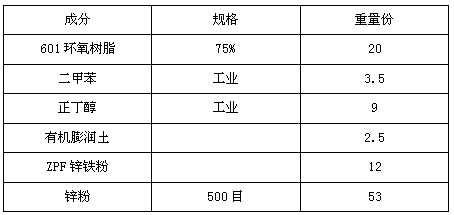

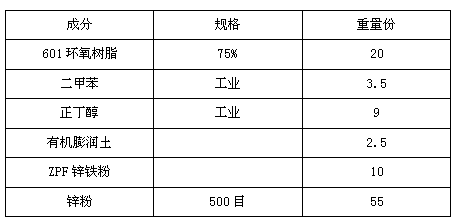

ZPF zinc-iron powder and application thereof in epoxy zinc-rich primer

InactiveCN110041804AEasy to processIncreased resistance to salt sprayAnti-corrosive paintsEpoxy resin coatingsEpoxyIron powder

The invention provides ZPF zinc-iron powder and application thereof in epoxy zinc-rich primer, and relates to the technical field of primer. The ZPF zinc-iron powder is prepared from the following components in percentage by mass: 30-40% of ferrophosphorus powder, 32-40% of powdered rock phosphate, 3-6% of zinc oxide, 8-12% of phosphate, 7-12% of silicate, 1-5% of titanium dioxide and 0.5-2% of aids; the epoxy zinc-rich primer is prepared from the following components in parts by weight: 15-25 parts of epoxy resin, 3-4 parts of xylene, 8-10 parts of n-butanol, 2-3 parts of organic bentonite, 8-12 parts of the ZPF zinc-iron powder and 50-60 parts of zinc powder. The ZPF zinc-iron powder and the application thereof in the epoxy zinc-rich primer, provided by the invention, have the beneficialeffects that the ZPF zinc-iron powder is easy to process and produce, can replace part of the zinc powder when applied to the epoxy zinc-rich primer, is beneficial to improving the salt spray resistance time of the epoxy zinc-rich primer, is of great help to the performance improvement of the epoxy zinc-rich primer, and is stronger in durable performance.

Owner:常州阿可德新材料科技有限公司

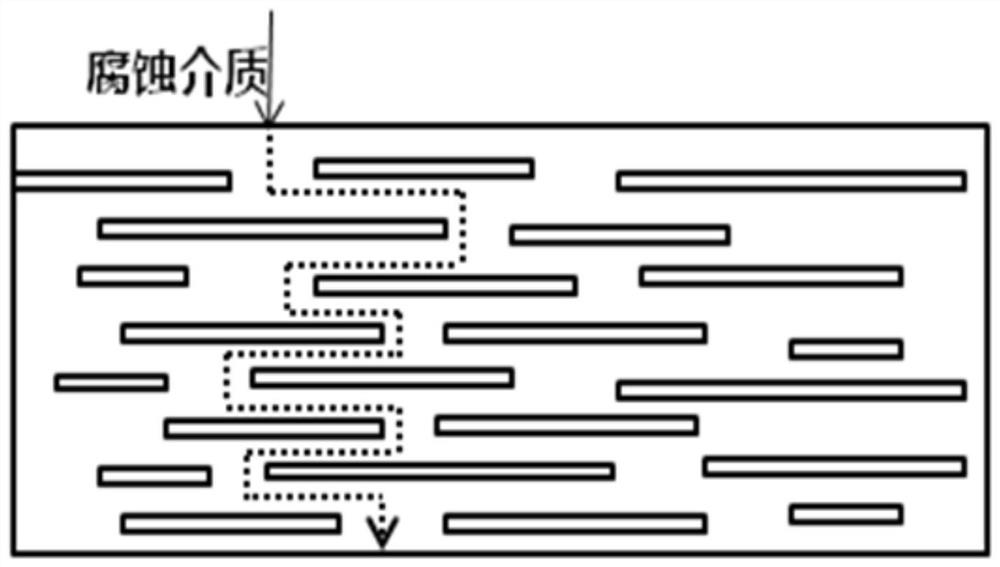

Preparation method of epoxy-resin-grafted glass scale filling material

ActiveCN102558910BSolve the problem of poor interface compatibilityReduce defectsAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPolymer science

The invention relates to a preparation method of an epoxy-resin-grafted glass scale filling material. The material is characterized in that the epoxy-resin-grafted glass scale filling material is prepared from raw materials of, by mass: 100 parts of glass scales, 0.5-90 parts of a bridging agent, 5-200 parts of epoxy resin, 0.0001-0.1 parts of a catalyst, and 100-10000 parts of a solvent. The preparation method of the epoxy-resin-grafted glass scale filling material comprises the steps that: first, preparation works are carried out, wherein the glass scales are subject to a drying treatment, epoxy resin is subject to a dewatering treatment, and the solvent is dewatered; polyisocyanate-modified glass scales are prepared; and then the epoxy-resin-grafted glass scale filling material is prepared. With the method provided by the invention, a problem of poor interfacial compatibility between anticorrosive resin paint and the glass scale filling material is solved, such that the corrosion resisting effect and the service life of an anticorrosive coating are substantially improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for improving the corrosion resistance of polyvinyl alcohol water-based coatings by heating and secondary curing

ActiveCN111574893BImprove adhesionImprove corrosion resistancePretreated surfacesAnti-corrosive paintsPolyvinyl alcoholGraphene

A method for improving the corrosion resistance of polyvinyl alcohol water-based coatings by heating and secondary curing, belonging to the technical field of coatings, the method adopts graphene, phosphor powder, SiO 2 , SiC is added to the polyvinyl alcohol solution as a mixed filler, and the coating is stabilized by secondary curing by heating. The invention utilizes the high thermal conductivity of nano fillers to improve the secondary curing efficiency, effectively reduce the binding sites of water molecules in the coating, and greatly reduce the water transport channels formed by polar groups in the coating, thereby improving the adhesion of the coating and corrosion resistance; at the same time, the secondary curing can strengthen the coating, enhance the combination of mixed fillers, further promote the barrier effect of graphene, and promote the formation of phosphorus and SiO 2 And SiC play its role in improving the cross-linking density of the coating to form a stable and dense three-dimensional network structure, thereby improving the compactness of the coating and achieving a better anti-corrosion effect; the method of the invention is safe and environmentally friendly, simple to operate, and has better realization sex.

Owner:NORTHEASTERN UNIV LIAONING

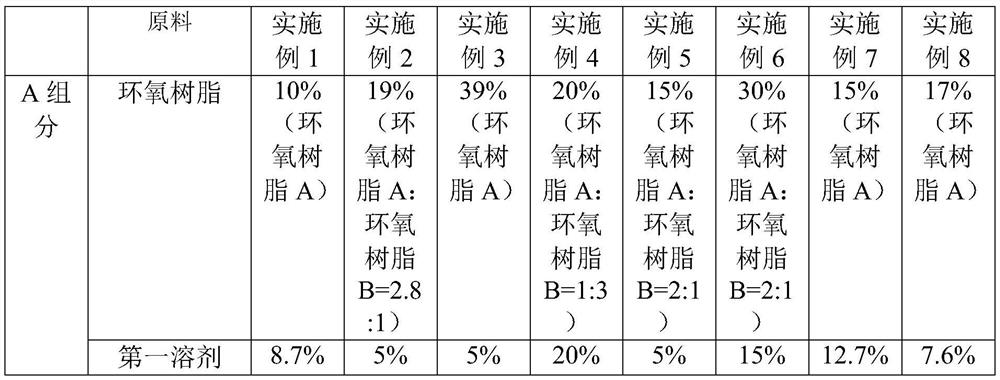

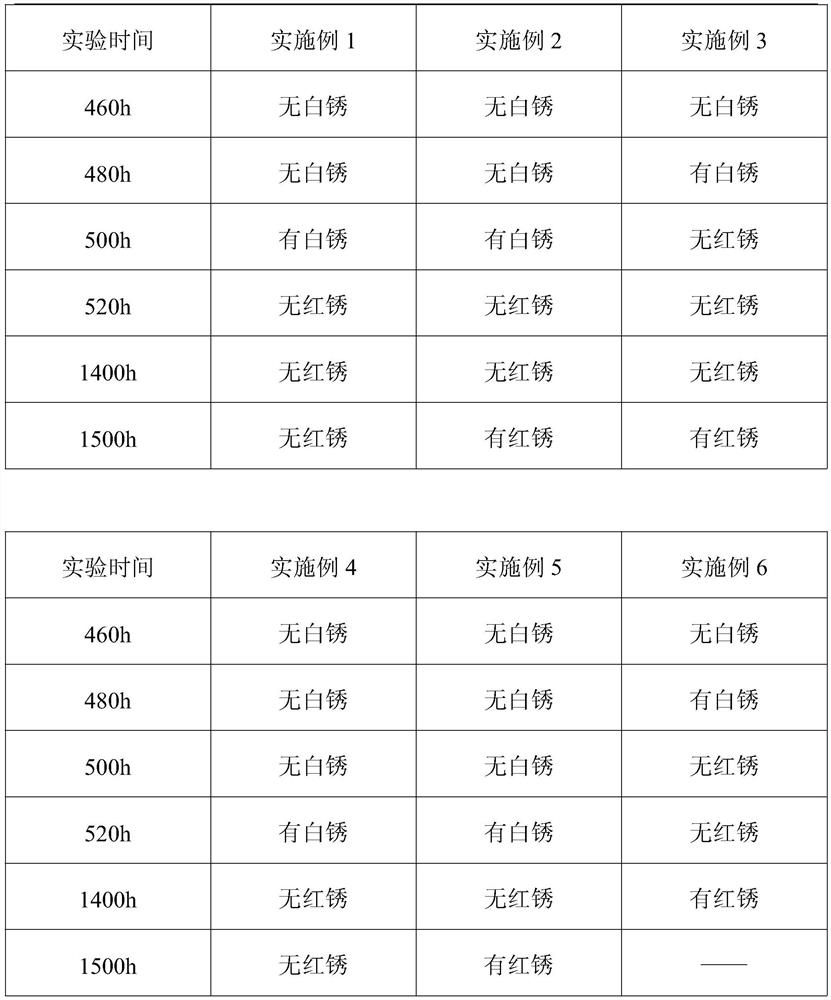

A method for improving the corrosion resistance of metal components

ActiveCN113045950BFavorable for lamellar distributionIncreased resistance to salt sprayLiquid surface applicatorsAnti-corrosive paintsEpoxyAlkene

The invention discloses a method for improving the corrosion resistance of metal components, which comprises the following steps: preparing component A and component B, mixing component A and component B at a mass percentage of 100:5-30 to obtain a scale-shaped Epoxy ethylene-zinc paint, the prepared flake type epoxy ethylene-zinc paint is sprayed on the metal member to be sprayed by HVLP spraying process, the spraying distance during HVLP spraying is 15-30cm, and the spraying air inlet pressure is 0.7-2.0 bar, the atomizing pressure of the hood is 0.2‑0.7 bar, and the compressed air flow rate is 15‑20 cfm. In the present invention, the prepared flake-type epoxy ethylene-zinc coating is applied to the surface of the metal member by HVLP spraying, the operation is simple, the content of metal zinc in the non-volatile matter of the metal member surface coating is reduced, and the salt spray resistance of the coating is improved, and the coating is improved. The corrosion resistance of metal components improves the performance and service life of metal components.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

Zinc-nickel alloy blue passivation agent and its preparation process

ActiveCN109252151BAvoid emissionsReduce lossesMetallic material coating processesChromium CompoundsOXALIC ACID DIHYDRATE

Owner:武汉风帆电化科技股份有限公司

A kind of exfoliating montmorillonite loaded organic amine curing agent and its preparation method and application

ActiveCN106893390BGood storage stabilityGood compatibilityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePtru catalyst

The invention belongs to the technical field of paint and particularly relates to a peeled type montmorillonoid loaded organic amine curing agent as well as a preparation method and application thereof. The curing agent is prepared from raw materials including montmorillonoid, amino acid, organic amine, a catalyst, a dispersant and a solvent, wherein a chemical structure is that an organic amine molecule is chemically grafted on the surface of a montmorillonoid nano-flake through quaternary ammonium salt of the amino acid; and the montmorillonoid nano-flake is at a peeled state. The peeled type montmorillonoid loaded organic amine curing agent can be uniformly dispersed into a coating formed by curing epoxy paint; the surface grafted organic amine molecule is used as a medium and the compatibility between the montmorillonoid nano-flake and epoxy resin in the paint is extremely improved; the problem of the montmorillonoid nano-flake that the interface compatibility is not good, caused by the fact that surface molecule structures of the organic epoxy resin is relatively great, is solved; and defects including agglomeration, separation, precipitation and the like of the montmorillonoid nano-flake in anticorrosive paint are avoided.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of epoxy resin grafted montmorillonite filler

ActiveCN102532954BFully strippedGood compatibilityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPolymer science

The invention relates to a preparation method of an epoxy resin grafted montmorillonite filler. The montmorillonite filler is prepared from the following raw materials: 100 of montmorillonite, 1-45 of organic amine, protonating agent same molar equivalent with organic amine, 0.5-300 of epoxy resin, 100-10000 of dispersant, and 10-5000 of solvent. The preparation method comprises the following steps of: firstly preparing organized montmorillonite; then adding epoxy resin to the organic montmorillonite, adding the solvent to regulate the viscosity of the reaction system, reacting at the temperature range of 15-140 DEG C for 1-24 hours, introducing epoxy resin molecules to the nano laminar surface of montmorillonite, and remaining the rest epoxide group; and stripping the nano lamella of montmorillonite to obtain the epoxy resin grafted montmorillonite filler. The obtained filler has few defects and pores, and can form a densified protective layer in an anti-corrosion coating, thereby significantly improving anticorrosion effect and service life of the anti-corrosion coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Machining face anticorrosion treatment method adopting painting procedure

InactiveCN110252628AEnhanced relative binding strengthImprove adhesionLiquid surface applicatorsAnti-corrosive paintsEpoxyPhosphate

The invention discloses a machining face anticorrosion treatment method adopting a painting procedure and belongs to the technical field of armored car machining. The problems that under the circumstances that a machining face of an armored car part cannot reach roughness needed by painting and oil on the machining face cannot be removed thoroughly by a common degreasing method, anticorrosion cannot be achieved through painting are solved. According to the machining face anticorrosion treatment method, oil on the surface of the machining face is removed thoroughly through electrolytic degreasing of an appropriate solution matching ratio, the requirement of a coating for roughness of the machining face of a substrate is lowered through high permeability and epoxy resin characteristics of high-strength epoxy phosphate primer, bonding strength of the coating and the substrate is enhanced, and rustproof and anticorrosion effects are achieved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

A kind of trivalent chromium multi-color passivator for galvanized layer and its preparation method and passivation treatment method

ActiveCN103849867BHigh hardnessHelps against wearMetallic material coating processesSucroseToxic material

The invention provides a multicolor trivalent chromium passivant for a zinc coating, and a preparation method and a passivation treatment method thereof. The multicolor trivalent chromium passivant for the zinc coating comprises 65-75g / L of chromic anhydride, 95-110g / L of sulfuric acid, 10-20g / L of sucrose, 10-200g / L of chromic nitrate, 10-100g / L of diffusant, 20-200g / L of cobalt nitrate, 10-200g / L of hydrofluoric acid, 5-150g / L of nitric aicd, 5-150g / L of DL-tartaric acid and the balance of water. The invention provides a preparation method and an application method for the passivant. Film layers of two colors can be obtained through passivation treatment of the passivant, one is a blue film layer and the other one is a colorful film layer, the product belongs to the environmentally-friendly passivant, is free from toxic substances such as hexavalent chromium, mercury, lead, cadmium, phenlyate and the like, thus having no damage to a human body and environments.

Owner:陕西美坚默克高科技发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com