Waterborne antirust and anticorrosion paint used for iron oxide red steel structure and preparation method of waterborne antirust and anticorrosion paint

An anti-rust, anti-corrosion, steel structure technology, applied in anti-corrosion coatings, latex paints, coatings, etc., can solve the problems of industrial painting, harmful to the painter's health, and the increase of steel structure painting costs, so as to improve the salt resistance. The effect of fog time, environmental protection, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

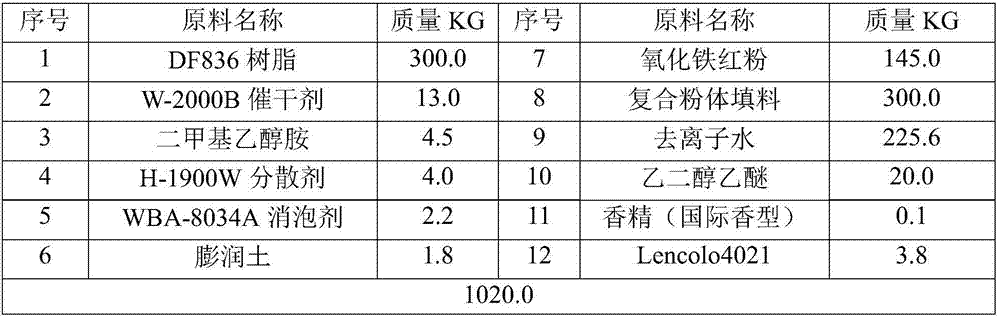

[0041] The formula that the single-component water-based interior wall engineering paint of the present embodiment specifically adopts is as follows

[0042]

[0043] Its preparation process and process are as follows:

[0044] 1. First add 300.0kg of DF836 water-based quick-drying alkyd resin to the pulling tank, start the disperser, add 13.0kg of W-2000B drier under low-speed stirring, and stir for 3-5 minutes at low speed; then add dimethylethanolamine to adjust the pH value Regulator 4.5kg will pH value to 7.5-8.5;

[0045] 2. After stirring well, add 225.6 kg of diluent deionized water, and stir for 3-5 minutes;

[0046]3. After stirring well, add 4.0kg of H-1900W dispersant, 2.2kg of WBA-8034A defoamer, 1.8kg of bentonite thickener, 3.8kg of Lencolo4021 salt spray resistance additive, 20.0kg of ethylene glycol ether film-forming additive, International flavor essence 0.1kg;

[0047] 4. Adjust the dispersing machine to a medium-high speed, then add 145.0kg of iron o...

Embodiment 2

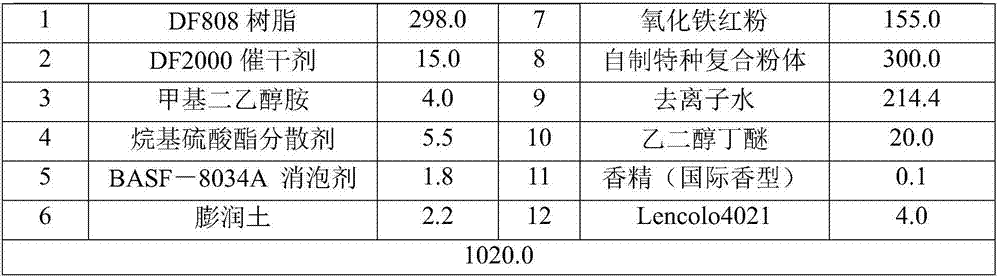

[0051] The formula that the single-component water-based interior wall engineering paint of the present embodiment specifically adopts is as follows

[0052]

[0053]

[0054] Its preparation process and process are as follows:

[0055] 1. First add 298.0kg of DF808 water-based quick-drying alkyd resin to the pulling tank, start the disperser, add 15.0kg of DF 2000 drier under low-speed stirring, and stir for 3-5 minutes at low speed; then add methyldiethanolamine to adjust the pH value Agent 4.0kg will pH value to 7.5-8.5;

[0056] 2. After stirring well, add 214.4kg of diluent deionized water and stir for 3-5 minutes;

[0057] 3. After stirring well, add 5.5kg of alkyl sulfate dispersant, 1.8kg of BASF-8034A defoamer, 2.2kg of bentonite thickener, 4.0kg of Lencolo4021 salt spray resistance additive, 20.0kg of ethylene glycol butyl ether film-forming additive, International flavor essence 0.1kg;

[0058] 4. Adjust the dispersing machine to a medium-high speed, and th...

Embodiment 3

[0062] The formula that the single-component water-based interior wall engineering paint of the present embodiment specifically adopts is as follows

[0063]

[0064] Its preparation process and process are as follows:

[0065] 1. First add 302.0kg of DF625 water-based quick-drying alkyd resin to the pulling tank, start the disperser, add 15.0kg of DriCAT408 drier under low-speed stirring, and stir for 3-5 minutes at low speed; then add triethylamine pH regulator 5.0 kg to bring the pH to 7.5-8.5;

[0066] 2. After stirring well, add 209.2kg of diluent deionized water and stir for 3-5 minutes;

[0067] 3. After stirring well, add 5.5kg of alkyl aryl sulfonate dispersant, 1.8kg of HT-8034A defoamer, 2.2kg of bentonite thickener, 4.2kg of Lencolo4021 salt spray resistance additive, and propylene glycol methyl ether film-forming additive 20.0kg, international flavor essence 0.1kg;

[0068] 4. Adjust the dispersing machine to a medium-high speed, and then add 155.0kg of iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt spray resistance time | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com