A kind of polyethylene polyamine-graphene hybrid curing agent and its preparation method and application method

A technology of polyethylene polyamine and its application method, which is applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as large differences in molecular structure and poor interface compatibility, and achieve improved salt spray resistance time , Good storage stability, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

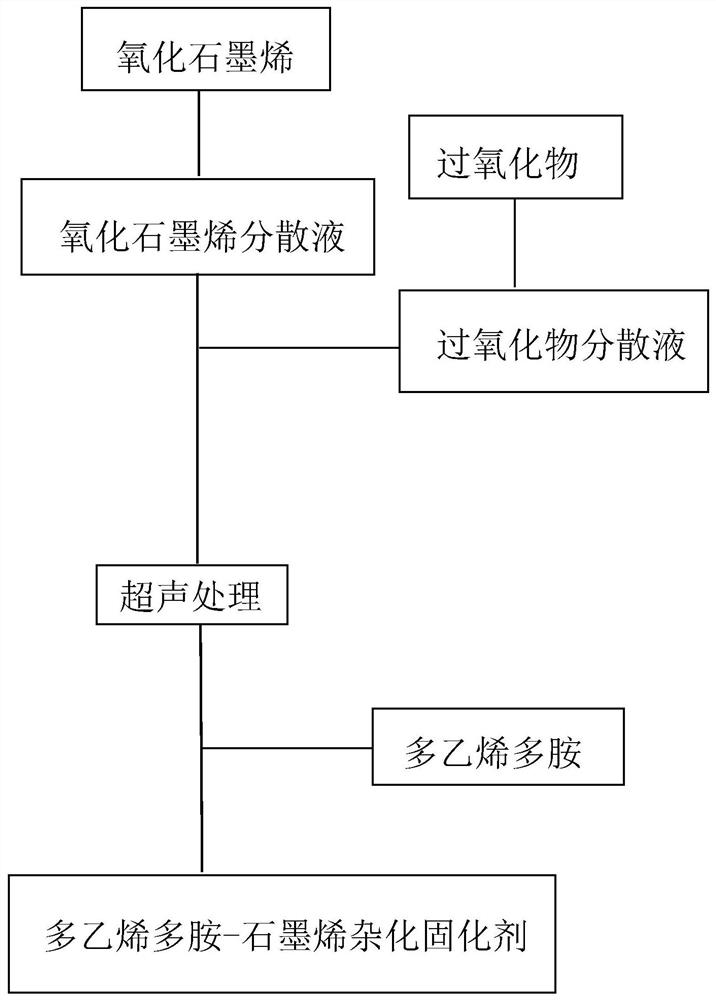

Method used

Image

Examples

Embodiment 1

[0023] First, 100 grams of multi-layer oxide oxide is first dispersed in 2000 grams of deionized water under stirring, and 200 grams of hydrogen peroxide is dispersed in 1000 grams of deionized water to prepare an oxide dispersion, followed by After stirring, the oxide dispersion droplets were added to the graphene dispersion to stir well, and the ultrasonic treatment was treated for 120 minutes, the ultrasonic treated product was centrifuged to remove deionized water, then add 180 grams of tetraethylene pentamine 120 ° C reaction. After 0.5 hours, the reaction was stopped, and the reaction product was repeatedly washed with deionized water, and the free compound was removed by centrifugation or filtered to give a polyvinyl-graphene hybrid curing agent.

[0024] 0.1 g of polyethylene polyamine-graphene hybrid fixing agent with 99.9 grams of epoxy quantity 455-556 (g.mol -1 The bisphenol F-type epoxy resin is mixed and uniform, and the coating is applied to the surface of the metal...

Embodiment 2

[0026] 100 grams of bilayer oxide oxide is first dispersed under stirring to prepare a graphene dispersion in 1000 grams of deionized water while dispersing 10 grams of sodium oxide is dispersed in 100 grams of deionized water to prepare a peroxide dispersion. Under stirring, the peroxide dispersion droplets were added to the oxide oxide dispersion to stir well, 10 minutes for ultrasonic treatment for 10 minutes, and the ultrasonic treatment was centrifuged to remove deionized water, and 10 grams of diethylene triamine room temperature reaction was added 24 hours. After the reaction, the reaction product was removed with deionized water and centrifuged or filtered to remove the free compound to give a polyethylene polyamine-graphene hybrid fixing agent.

[0027] 30 grams of polyethylene polyamine-graphene hybrid curing agent and 70 grams of epoxy equivalent 185-208 (g.mol -1 After mixing the aliphatic epoxy resin, the coating is applied to the surface of the metal test piece with ...

Embodiment 3

[0029] The 100 grams of oxidation of multi-layer graphene was first dispersed under the stirred conditions of 2000 g of carbide dispersion, and 10 grams of oxidized dibenzoyl is dispersed in 100 g of toluene to prepare an oxide dispersion. Next, the peroxide dispersion droplets were stirred evenly under stirring, and the mixture was mixed well, and the reaction product was stopped after 2 hours by ultrasonic treatment for 2 hours, and the reaction product was stopped using ultrasonic waves. Repeated washing, and the free compound was removed or filtered to give a polyvinyl amine-graphene hybrid curing agent.

[0030] 3 g of a polyethylene polyamine-graphene hybrid curing agent was mixed with 97 g of an epoxy equivalent 455-556 (g. Mol-1), and the coating was applied with a dipping method. The surface of the metal test was solidified for two weeks at room temperature. In the same mass ratio of unreformed oxidation, multi-layer graphene is added to the epoxy resin of the same mass, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com