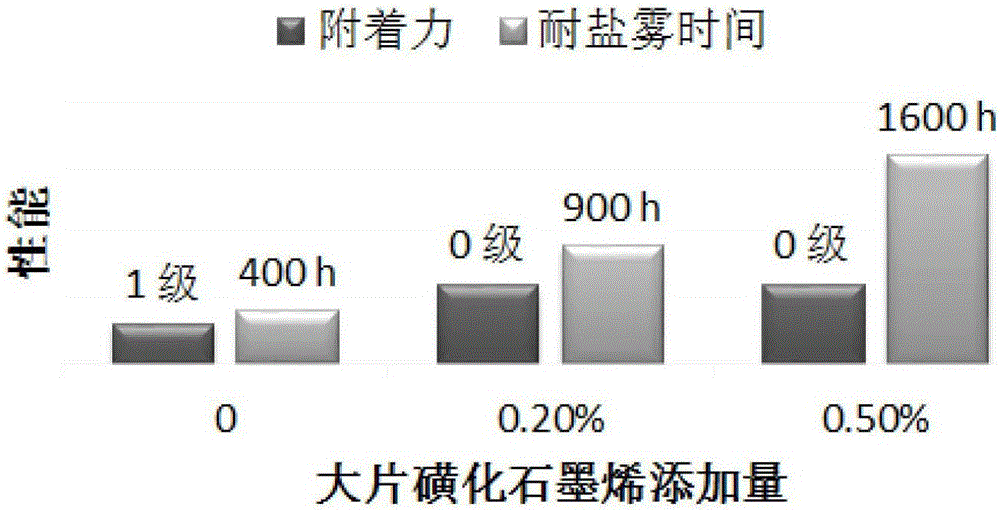

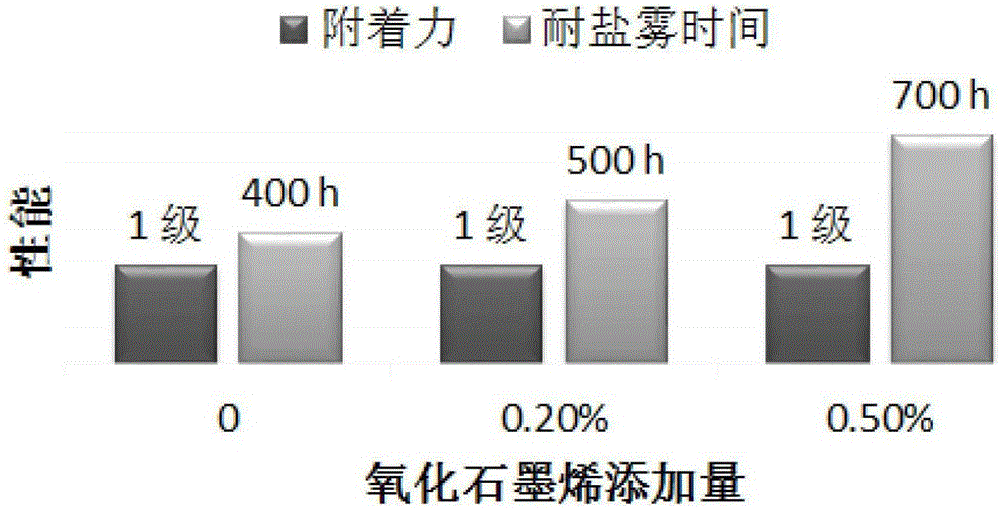

Graphene-modified water-based epoxy zinc-enriched coating as well as preparation method and application thereof

A water-based epoxy zinc-rich and graphene-modified technology, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of limited improvement in coating performance, achieve excellent anti-corrosion performance, wide application prospects, The effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle of the present invention will be further explained in conjunction with several embodiments and accompanying drawings as follows. However, those skilled in the art can refer to the contents herein to appropriately improve the process parameters to realize. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The application of the present invention has been described through the preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the application described herein without departing from the content, spirit and scop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com