ZPF zinc-iron powder and application thereof in epoxy zinc-rich primer

A technology of epoxy zinc-rich primer and zinc-iron powder, which is applied in the field of primers, can solve the problems of short salt spray resistance time of epoxy zinc-rich primer, achieve improved salt spray resistance time, strong durability, and easy processing and production simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] see figure 2 , the ZPF zinc-iron powder described in the present embodiment comprises the following components by weight percentage: 40% of iron-phosphorus powder, 32% of phosphate rock powder, 4% of zinc oxide, 10% of phosphate, 7% of silicate, 5% of titanium dioxide , organic silicon 2%; put the above-mentioned percentage by weight of ferrophosphorus powder, phosphate rock powder, zinc oxide, phosphate, silicate, titanium dioxide and additives into the mixing and stirring equipment in turn, and turn on the mixing and stirring equipment after the feeding is completed. Flying knife for stirring, stirring time is 30min; after stirring, use sampling equipment to carry out sampling inspection, after passing the inspection, start packaging.

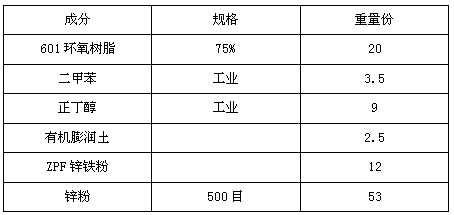

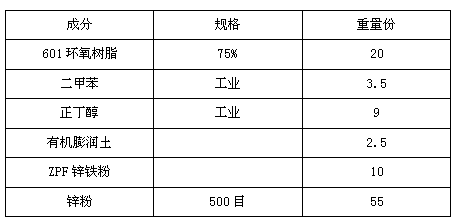

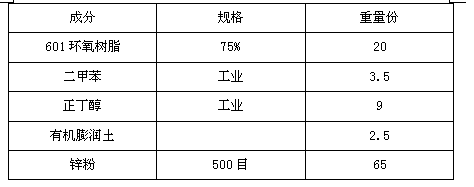

[0027] The ZPF zinc-iron powder processed above is used to replace part of the zinc powder, and is applied in the epoxy zinc-rich primer. The epoxy zinc-rich primer is composed of the following components by weight: 20 parts of epoxy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com