Zinc-nickel alloy blue passivator and preparation method thereof

A zinc-nickel alloy and preparation process technology, applied in the direction of metal material coating process, etc., can solve the problems of various types of chromium-free passivation processes, cannot meet the requirements of industrialization, and weak anti-corrosion ability, etc., achieve good chemical polishing effect, effective It is beneficial to the point deposition of chromium and the effect of low resistance of the plating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

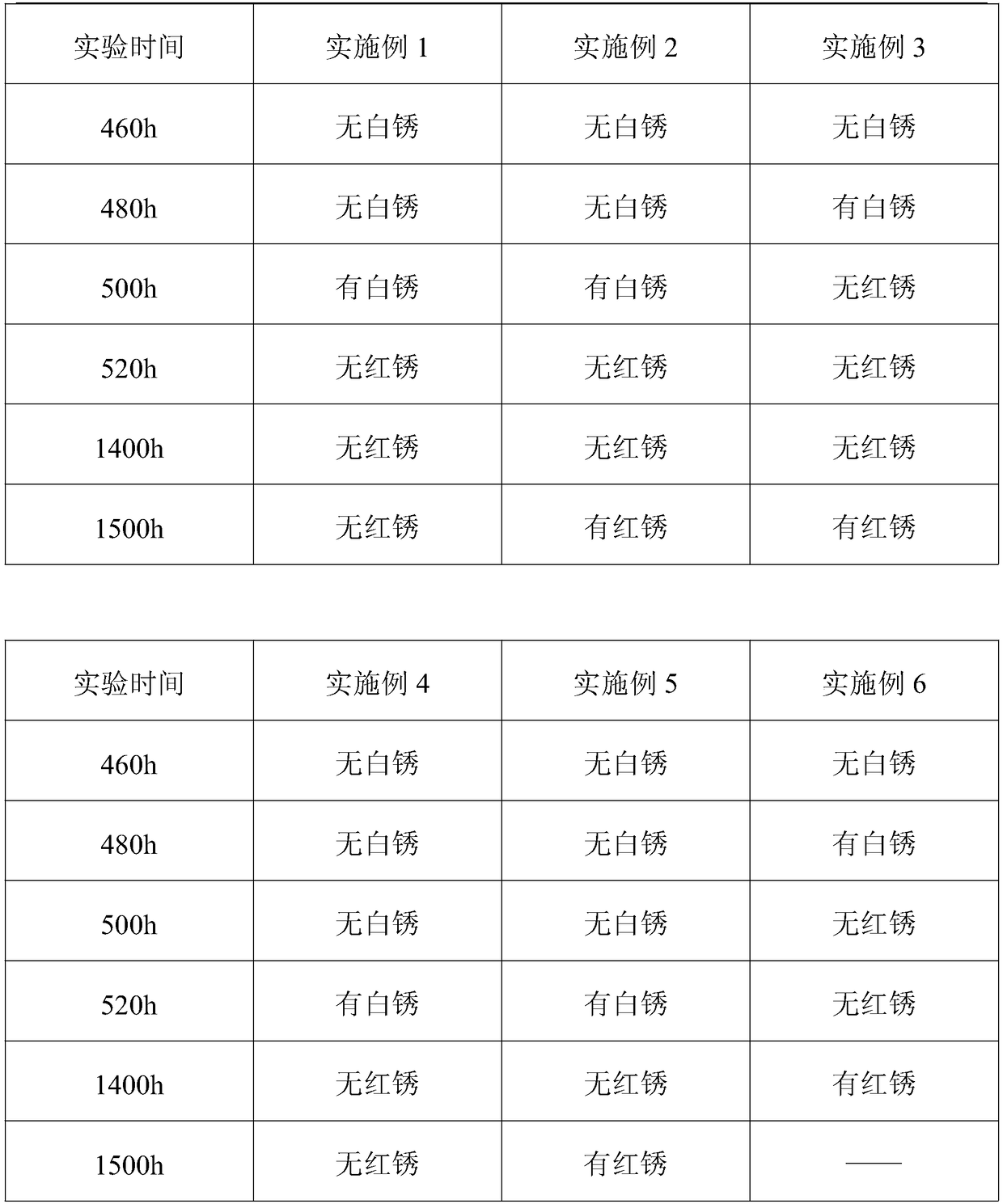

Embodiment 1

[0040] Weigh 150g of chromium chloride, 40g of citric acid, 10g of oxalic acid, 10g of trisodium phosphate and 400ml of water, mix them, heat to 70°C, heat and stir for 2 hours, after the heat preservation is completed, let stand and cool down to 20°C to obtain a trivalent chromium compound solution. Weigh 70g of sodium hydroxide, 20g of ammonium sulfate and 200ml of water, mix and stir until the sodium hydroxide and ammonium sulfate are completely dissolved, let stand and cool to 20°C to obtain a mixed solution, and add the mixed solution dropwise to the trivalent chromium compound solution Add 10ml of water to obtain Agent A after the dropwise addition is completed;

[0041] Weigh 70g of cobalt nitrate, 50g of nickel sulfate, 10g of sodium nitrate, 10g of citric acid and 860ml of water, mix and dissolve to obtain Agent B;

[0042] Heat 20ml of Agent A, 40ml of Agent B and 940ml of water prepared in this example to 25°C, mix and stir for 5 minutes, let stand for 2 hours, adju...

Embodiment 2

[0044] Weigh 210g of chromium hydroxide, 45g of citric acid, 30g of oxalic acid, 20g of trisodium phosphate and 300ml of water, mix them, heat to 80°C, heat and stir for 3 hours, after the heat preservation is completed, let stand and cool down to 25°C to obtain a trivalent chromium compound solution, Weigh 80g of sodium hydroxide, 25g of ammonium chloride and 200ml of water, mix and stir until the sodium hydroxide and ammonium chloride are completely dissolved, let stand and cool to 25°C to obtain a mixed solution, and add the mixed solution dropwise to trivalent chromium Compound solution and stirred, after the dropwise addition, add 90ml of water to obtain agent A;

[0045] Weigh 100g of cobalt sulfate, 100g of nickel chloride, 15g of sodium chloride, 15g of tartaric acid and 770ml of water, mix and dissolve to obtain B agent;

[0046] Heat 25ml of agent A, 50ml of agent B and 925ml of water prepared in this example to 30°C, mix and stir for 10 minutes, let stand for 2 hour...

Embodiment 3

[0048] Weigh 270g of chromium sulfate, 60g of citric acid, 40g of oxalic acid, 30g of trisodium phosphate and 200ml of water, mix them, heat to 90°C, keep stirring for 4 hours, after the heat preservation is completed, let stand and cool down to 30°C to obtain a trivalent chromium compound solution, weigh Take 90g of sodium hydroxide, 10g of ammonium chloride, 20g of ammonium oxalate and 200ml of water, mix and stir until the sodium hydroxide is completely dissolved, let stand and cool to 30°C to obtain a mixed solution, and add the mixed solution dropwise to the trivalent chromium compound solution and stirred, after the dropwise addition, add 140ml of water to obtain agent A;

[0049] Weigh 100g of cobalt nitrate, 30g of cobalt sulfate, 100g of nickel sulfate, 50g of nickel chloride, 20g of sodium molybdate, 15g of citric acid, 5g of tartaric acid and 680ml of water, mix and dissolve to obtain B agent;

[0050] Heat 30ml of agent A, 60ml of agent B and 910ml of water prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com