A method for improving the corrosion resistance of metal components

A metal component, corrosion-resistant technology, used in anti-corrosion coatings, devices for coating liquid on surfaces, coatings, etc. and other problems, to achieve the effect of improving electrochemical protection, increasing electrochemical protection, and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

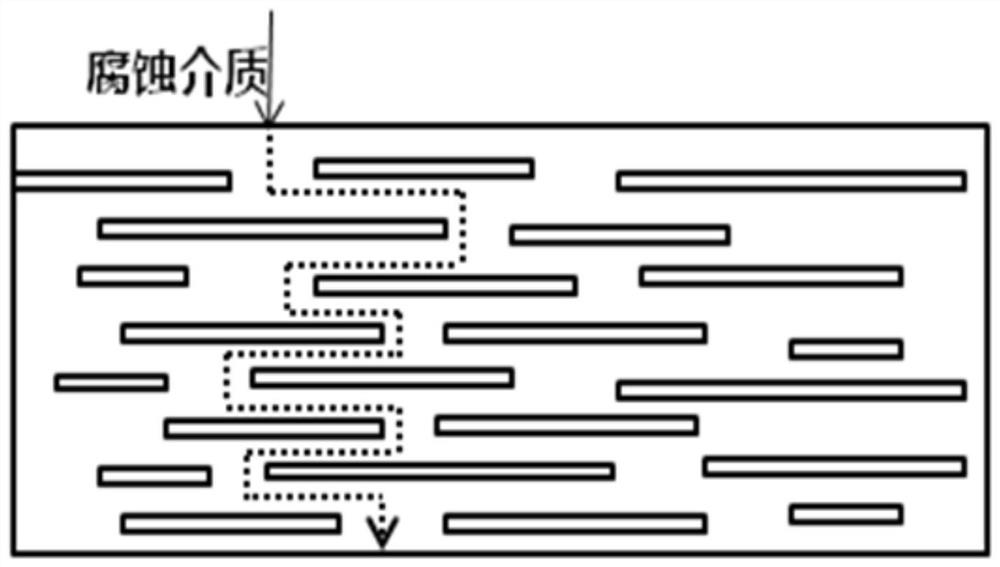

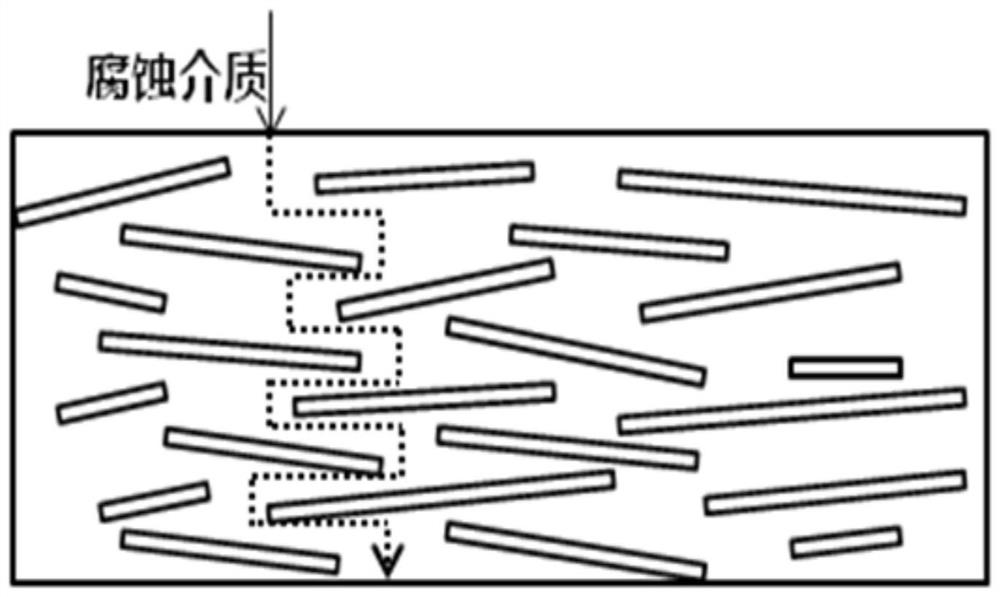

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for improving corrosion resistance of metal components, comprising the following steps:

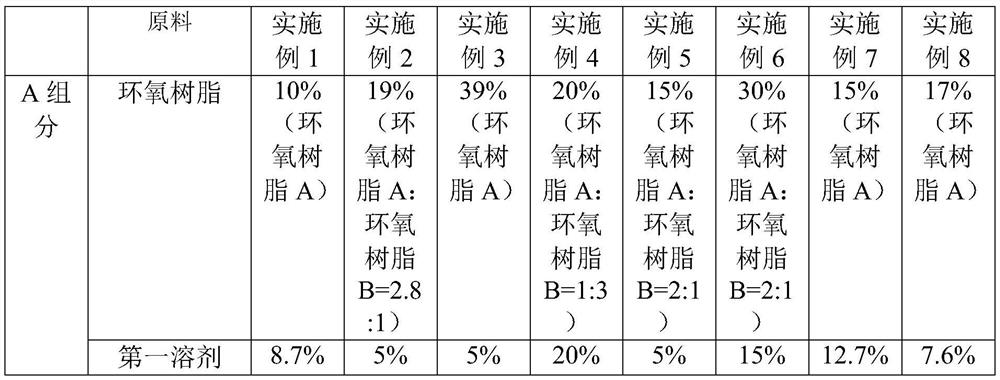

[0053] S1, prepare the scaly type epoxy alkene-zinc coating, prepare the A component and the B component according to the mass percentage in the following table 1, then mix the A component and the B component with the mass percentage to be 100:15 ratio to make the scale type epoxy olefin-zinc coating;

[0054] The order of adding the raw materials in the process is as follows: for component A, first mix the epoxy resin with the first solvent, then add the nano-pigment filler dispersant and graphene oxide, and obtain the graphene resin dispersion slurry by fully dispersing, and then Add wetting assistant, defoamer (silicon-free foam-breaking polymer solution defoamer), silicone assistant, and finally add zinc powder and nano anti-rust pigment to obtain component A;

[0055] For component B, directly mix the curing agent with the second solvent;

[0056] S2, the obtained s...

Embodiment 2-28

[0058] A method for improving the corrosion resistance of metal components is carried out according to the method in Example 1, the difference is that the mass percentage of raw materials in the scaly epoxy-zinc coating is prepared according to the following table 1, and in Example 3 The defoamer is an organic silicon defoamer.

[0059] Table 1:

[0060]

[0061]

[0062] Continued from Table 1:

[0063]

[0064]

[0065] Continued from Table 1:

[0066]

[0067]

[0068] Continued from Table 1:

[0069]

Embodiment 29

[0071] A method for improving the corrosion resistance of metal components is carried out according to the method in Example 17, the difference is that the A component and the B component are mixed with a mass percentage of 100:5 to prepare a scaly epoxy-zinc primer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com