Multicolor trivalent chromium passivant for zinc coating, and preparation method and passivation treatment method thereof

A passivation treatment, galvanized layer technology, applied in the direction of metal material coating process, etc., can solve the problems of single color and complicated use, and achieve the effect of reducing production cost, simple operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

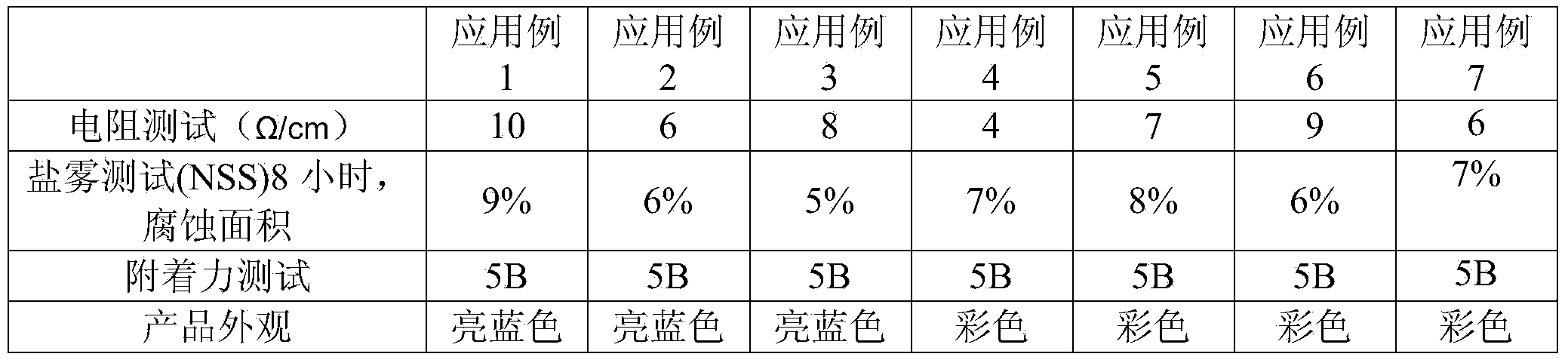

Examples

preparation example Construction

[0019] A kind of preparation method of the trivalent chromium multi-color passivator of galvanized layer, comprises the following steps:

[0020] 1) First add an appropriate amount of water to the enamel reactor, turn on the agitator, and then add chromic anhydride. After the chromic anhydride is completely dissolved, slowly add sulfuric acid under constant stirring. When the reaction temperature does not exceed 85°C, slowly add The sucrose is catalyzed, and when the solution in the reactor becomes a dark green state, the reaction ends at this moment, and the basic chromium sulfate aqueous solution is obtained;

[0021] 2) Cool down to 30-40°C, add chromium nitrate, diffusing agent, cobalt nitrate, hydrofluoric acid, citric acid, DL-tartaric acid in turn, after the raw materials are completely dissolved, add water to the total volume, and stir evenly to obtain the finished product.

[0022] In the following examples, the water used is distilled water, and the diffusing agent i...

Embodiment 1

[0025] A trivalent chromium multi-color passivator for galvanized layer, comprising chromic anhydride 69.9g / L, sulfuric acid 103.9g / L, sucrose 16.2g / L, chromium nitrate 40g / L, diffusing agent 20g / L, cobalt nitrate 80g / L, hydrofluoric acid 40g / L, citric acid 20g / L, DL-tartaric acid 20g / L, and the rest is water.

[0026] A kind of preparation method of the trivalent chromium multi-color passivator of galvanized layer, comprises the following steps:

[0027] 1) First add 210ml of water to the enamel reactor, turn on the agitator, then add chromic anhydride, after the chromic anhydride is completely dissolved, slowly add sulfuric acid under constant stirring, and slowly add sucrose to catalyze at a controlled reaction temperature of 85°C Reaction, when the solution in the reactor becomes a dark green state, the reaction ends at this moment, and the basic chromium sulfate aqueous solution is obtained;

[0028] 2) Cool down to 30-40°C, add chromium nitrate, diffusing agent, cobalt...

Embodiment 2

[0030] A kind of trivalent chromium multi-color passivator of galvanized layer, comprises chromic anhydride 65g / L, sulfuric acid 95g / L, sucrose 10g / L, chromium nitrate 10g / L, diffusion agent 10g / L, cobalt nitrate 20g / L, Hydrofluoric acid 10g / L, citric acid 5g / L, DL-tartaric acid 5g / L, and the rest is water.

[0031] A kind of preparation method of the trivalent chromium multi-color passivator of galvanized layer, comprises the following steps:

[0032] 1) First add 300ml of water to the enamel reactor, turn on the agitator, then add chromic anhydride, after the chromic anhydride is completely dissolved, slowly add sulfuric acid under constant stirring, and slowly add sucrose to catalyze at a controlled reaction temperature of 80°C Reaction, when the solution in the reactor becomes a dark green state, the reaction ends at this moment, and the basic chromium sulfate aqueous solution is obtained;

[0033] 2) Cool down to 30-40°C, add chromium nitrate, diffusing agent, cobalt nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com