Rust transfer agent and preparation method thereof

A technology of rust transfer agent and water-based defoamer, used in anti-corrosion coatings, coatings, etc., can solve problems such as environmental hazards, and achieve the effects of improved salt spray resistance, low cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

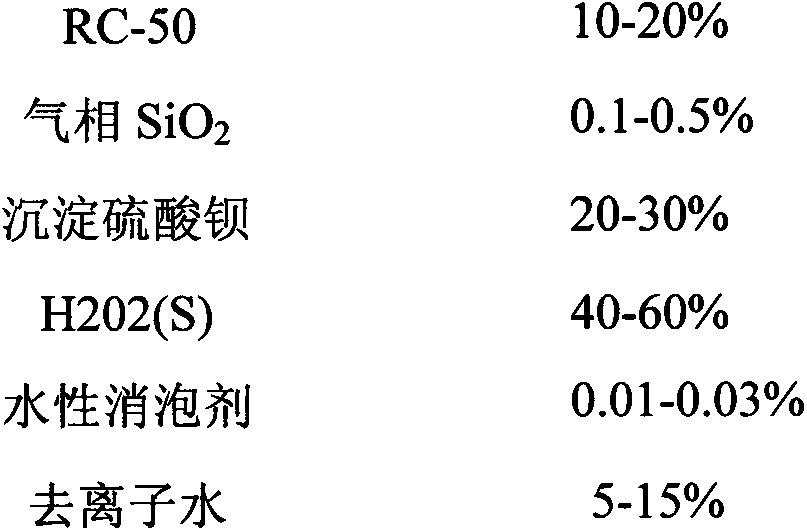

Embodiment 1

[0025] Add 217.7g of RC-50 and 747g of H2O2(S) into 105g of deionized water and disperse at high speed; add 0.36g of water-based defoamer into the mixed solution of high-speed dispersion; finally add 105g of phase SiO 2 And 345g precipitated barium sulfate, stir well.

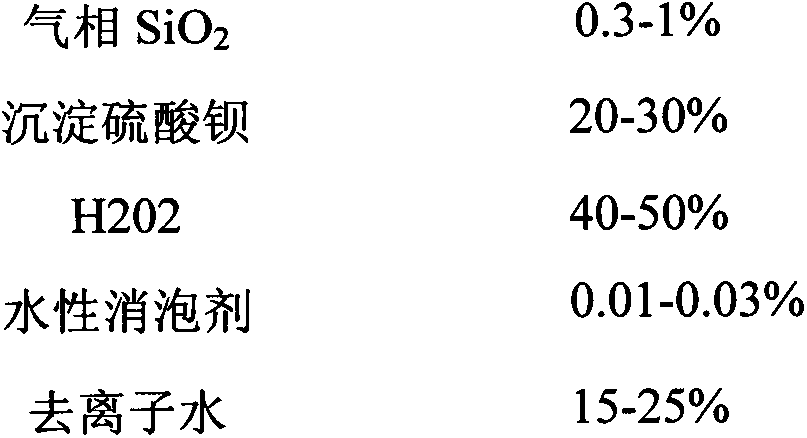

Embodiment 2

[0027] Add 213.5g of RC-50 and 732.6g of H2O2 into 306g of deionized water and disperse at high speed; add 0.32g of water-based defoamer to the mixed solution of high-speed dispersion; finally add 8.37g of gas phase SiO 2 and 337.7g of precipitated barium sulfate, stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com