Waterglass-polymer homogeneous phase hybrid modified precursor liquid for lumber and preparation method thereof

A technology of wood modification and hydrophilic polymer, which is applied in the direction of wood impregnation, impregnated wood, wood processing utensils, etc., can solve the problems of environmental and human hazards, the brittleness of the alkaline silica gel film layer, and the increase of wood brittleness, etc., to achieve The preparation process is simple and easy to overcome the problem of water loss and the effect of good interface affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

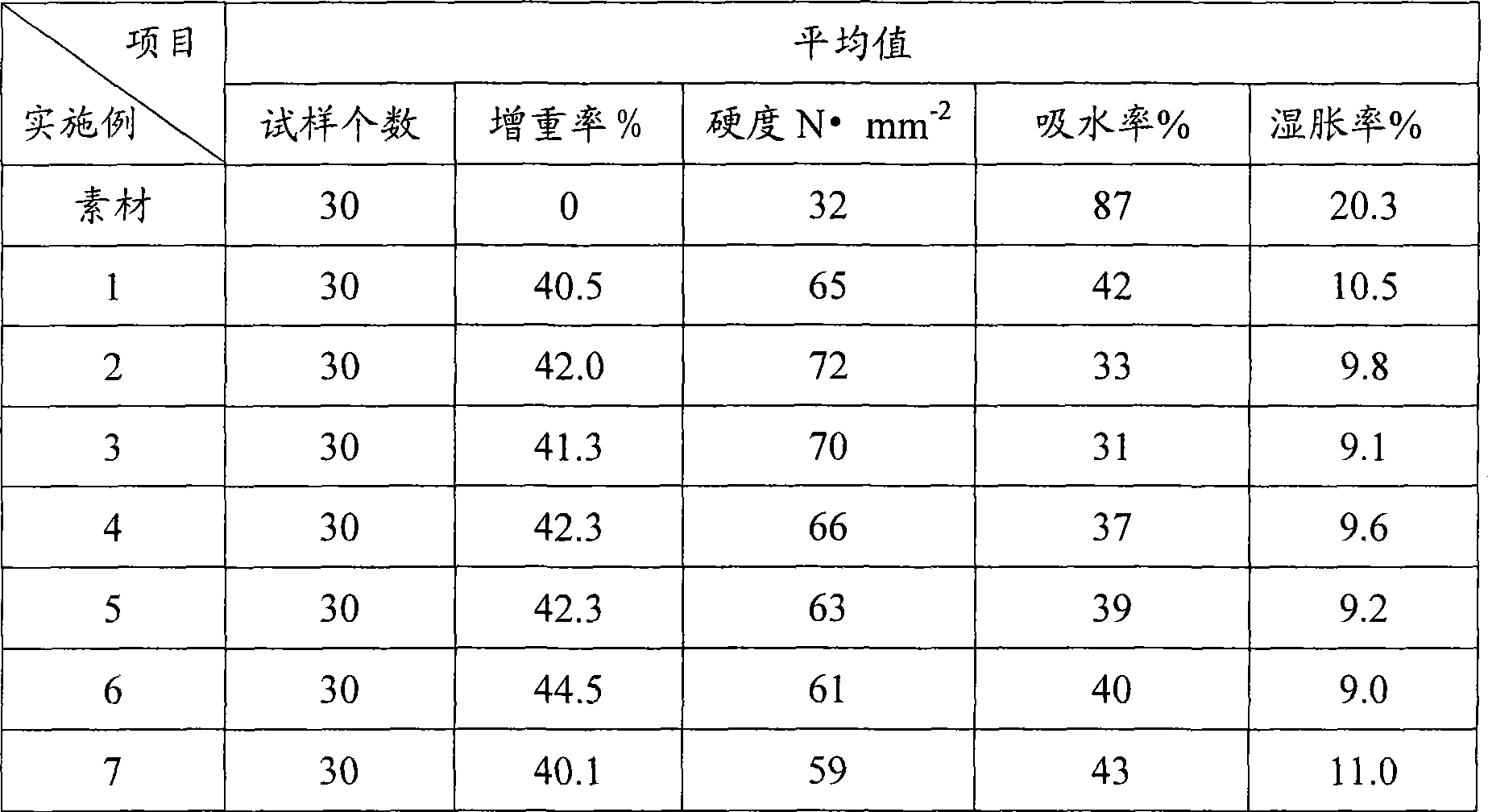

Examples

Embodiment 1

[0019] 1) Dissolve 4.2g of sodium polyacrylate in 95.8g of water in a reaction kettle at room temperature, and fully stir at 90°C to form a transparent homogeneous solution;

[0020] 2) Mix 100g of sodium polyacrylate solution prepared in step 1) and 29.8g of sodium water glass at 30°C. After stirring thoroughly, add 3.48g of N,N-methylenebisacrylamide, and continue stirring for 1h , a clear, homogeneous water glass-sodium polyacrylate hybrid solution was obtained.

[0021] The viscosity of the solution is 56 mPa·s, and the solubility after soaking in water for 24 hours is 3.5%.

Embodiment 2

[0023] 1) Dissolve 0.2g of sodium polyacrylate in 99.8g of water in a reaction kettle at room temperature, and fully stir at 30°C to form a transparent homogeneous solution;

[0024] 2) Mix 100g of sodium polyacrylate solution prepared in step 1) and 100g of sodium water glass at 80°C, and after stirring thoroughly, add 6.01g of N,N-methylenebisacrylamide, and continue stirring for 3h to obtain Clear, homogeneous water glass-sodium polyacrylate hybrid solution.

[0025] The viscosity of the solution is 63 mPa·s, and the solubility after soaking in water for 24 hours is 2.7%.

Embodiment 3

[0027] 1) Dissolve 3.0g of sodium polyacrylate in 97.0g of water in a reaction kettle at room temperature, and fully stir at 60°C to form a transparent homogeneous solution;

[0028] 2) Mix 100g of sodium polyacrylate solution prepared in step 1) and 60g of sodium water glass at 80°C, and after fully stirring, add 4.5g of N,N-methylenebisacrylamide, and continue stirring for 2h to obtain Clear, homogeneous water glass-sodium polyacrylate hybrid solution.

[0029] The viscosity of the solution is 89 mPa·s, and the solubility after soaking in water for 24 hours is 1.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com