Linear compressor with magnetic spring structure

A technology of linear compressors and magnetic springs, applied in the direction of magnetic springs, springs, springs/shock absorbers, etc., can solve the problems of reduced reliability and stability, reduced compressor performance, gas leakage, etc., and achieves compact structure and easy processing Simple, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

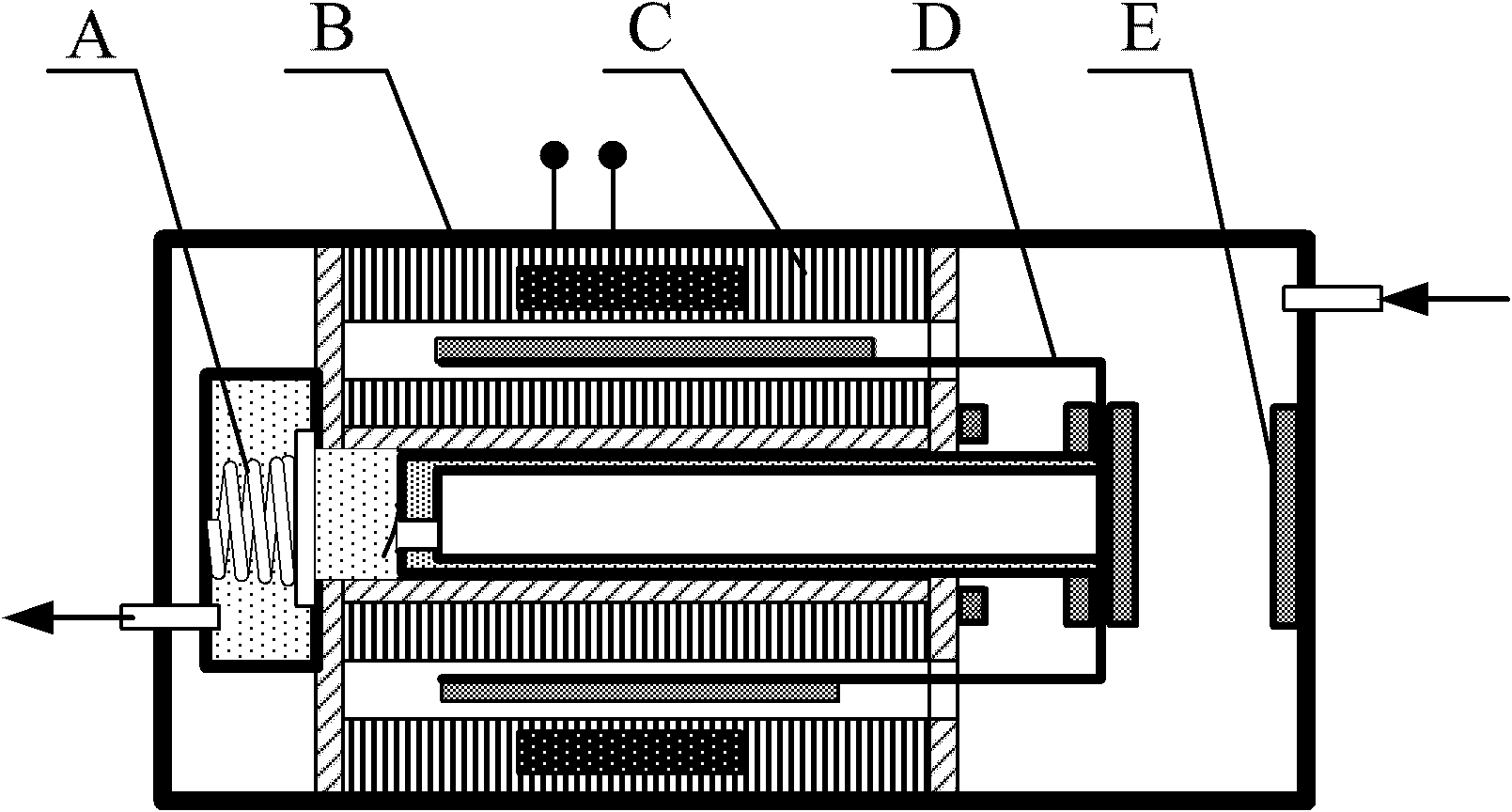

[0024] Accompanying drawing is the specific embodiment of the present invention;

[0025] Below in conjunction with accompanying drawing, content of the present invention is described in further detail:

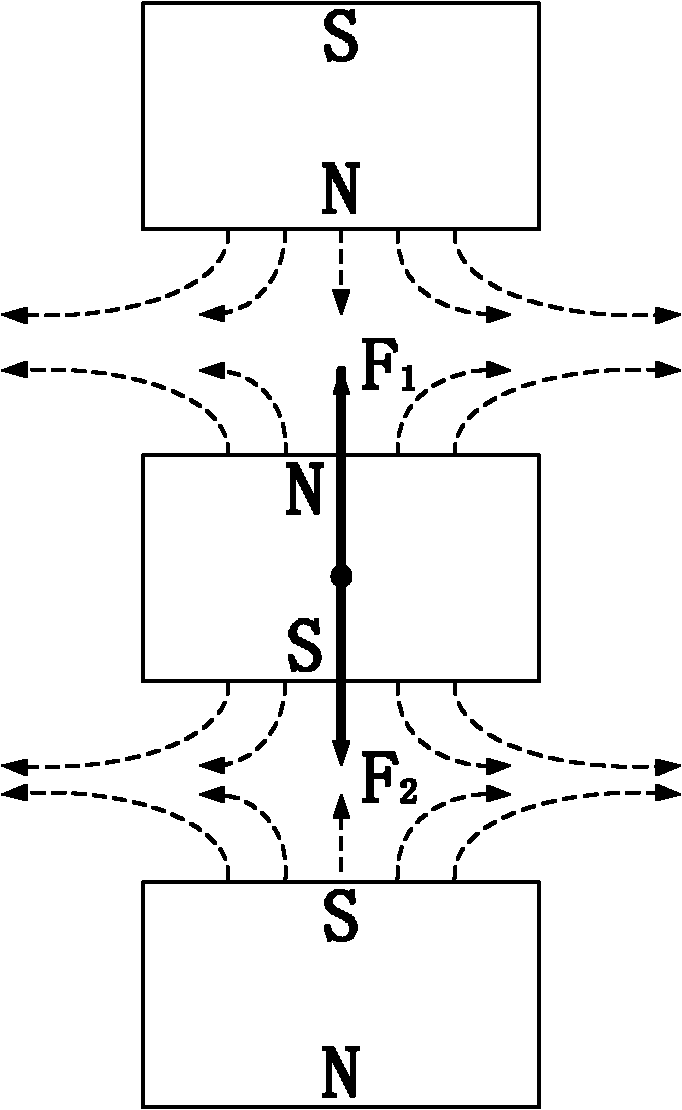

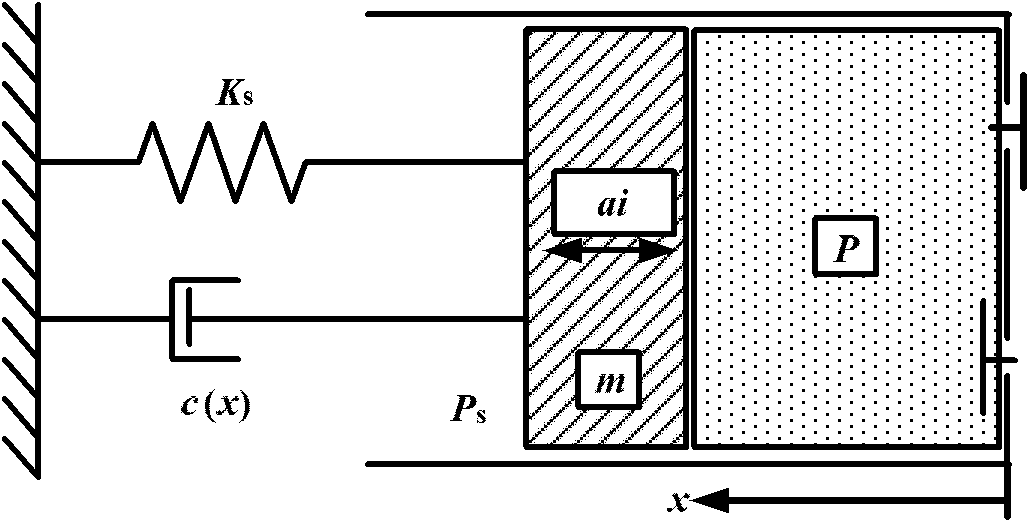

[0026] figure 1 It is a schematic diagram of a magnetic spring, which consists of three sets of permanent magnets. The upper and lower permanent magnets are in a fixed state, and the middle permanent magnet is in a free-moving state. The permanent magnets are placed in the same direction, and the moving magnet in the middle is subjected to the repulsive force F of the upper and lower fixed magnets 1 and F 2 Effect, when the resultant force is zero, the moving magnet is in a balanced state. Without considering the gravity of the moving magnet itself, the resultant force on the moving magnet is

[0027] F s ( x ) = π B r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com