Antifriction bearing surface damage fault dynamics modeling method

A dynamic modeling, rolling bearing technology used in mechanical bearing testing, instrumentation, testing of machine/structural components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with the accompanying drawings.

[0084] The rolling bearing surface damage fault dynamics modeling method of the present invention comprises the following steps:

[0085] 1. Rolling bearing inner ring fault model

[0086] Considering the rolling bearing clearance, the magnitude of the impact force produced by the rolling element passing through the damage point will vary depending on the position of the damage point in the load-bearing area. Neglecting the relative sliding of the contact surface, the movement of the inner ring can be regarded as A two-degree-of-freedom mass-spring-damper system.

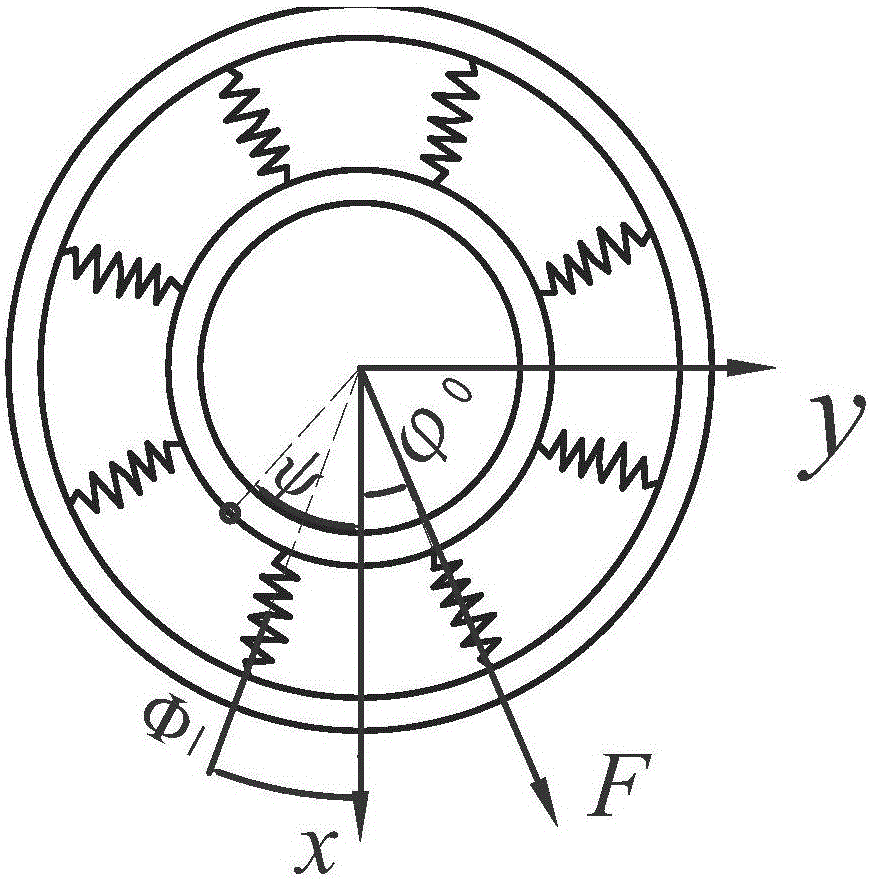

[0087] Such as figure 1 As shown, the effect force of the load on the inner ring through the shaft and the impact force generated by the local surface damage of the bearing are regarded as external loads and act on the inner ring, and the deformation at the position of the i-th rolling element is δ i , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com