Sling-type low-gravity simulation tension control buffer mechanism and adjustment method

A tension control and buffer mechanism technology, which is used in the testing of machinery/structural components, simulation devices for space navigation conditions, measurement devices, etc., and can solve the problems of high bandwidth and difficulty in controlling the bandwidth of the control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

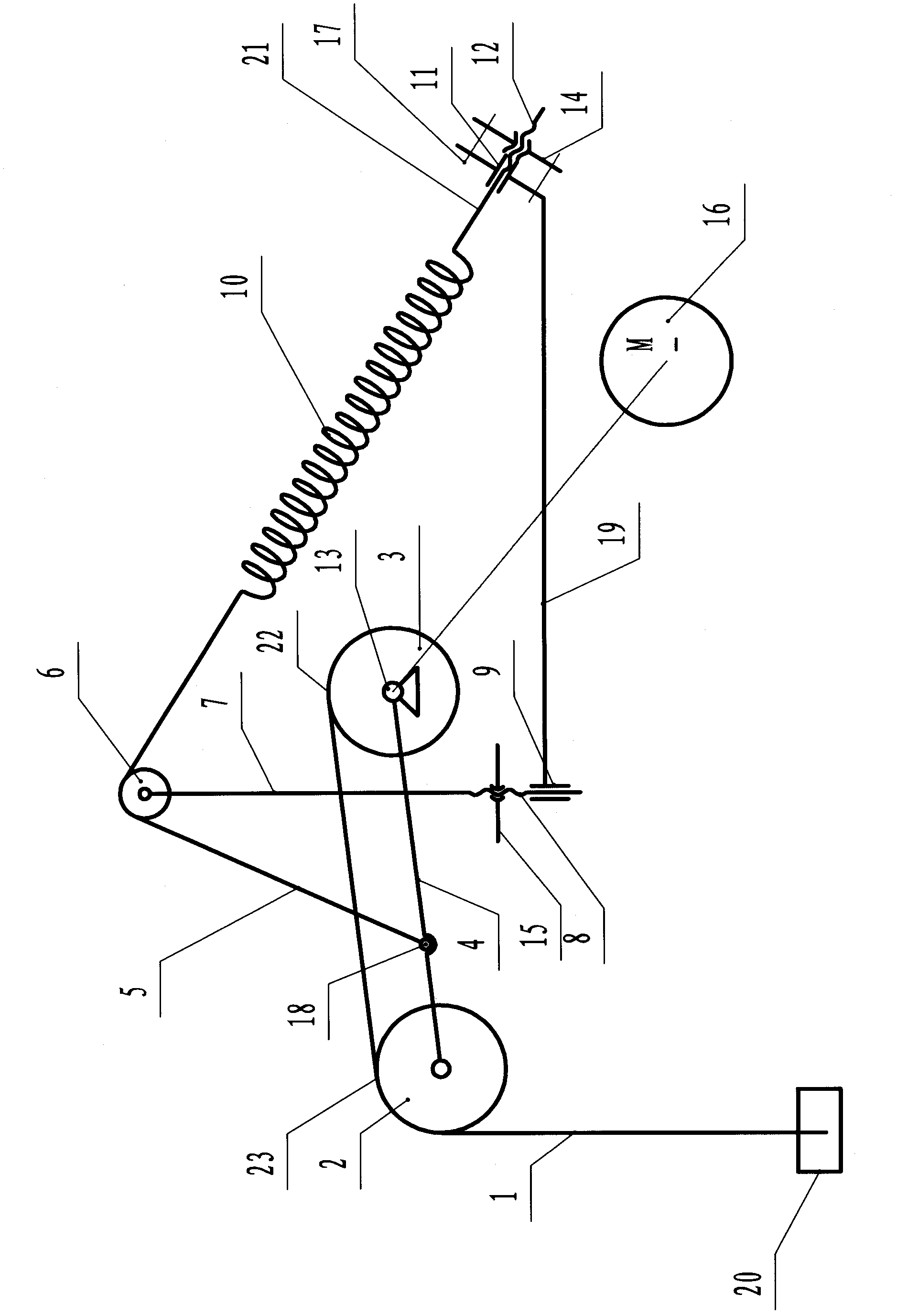

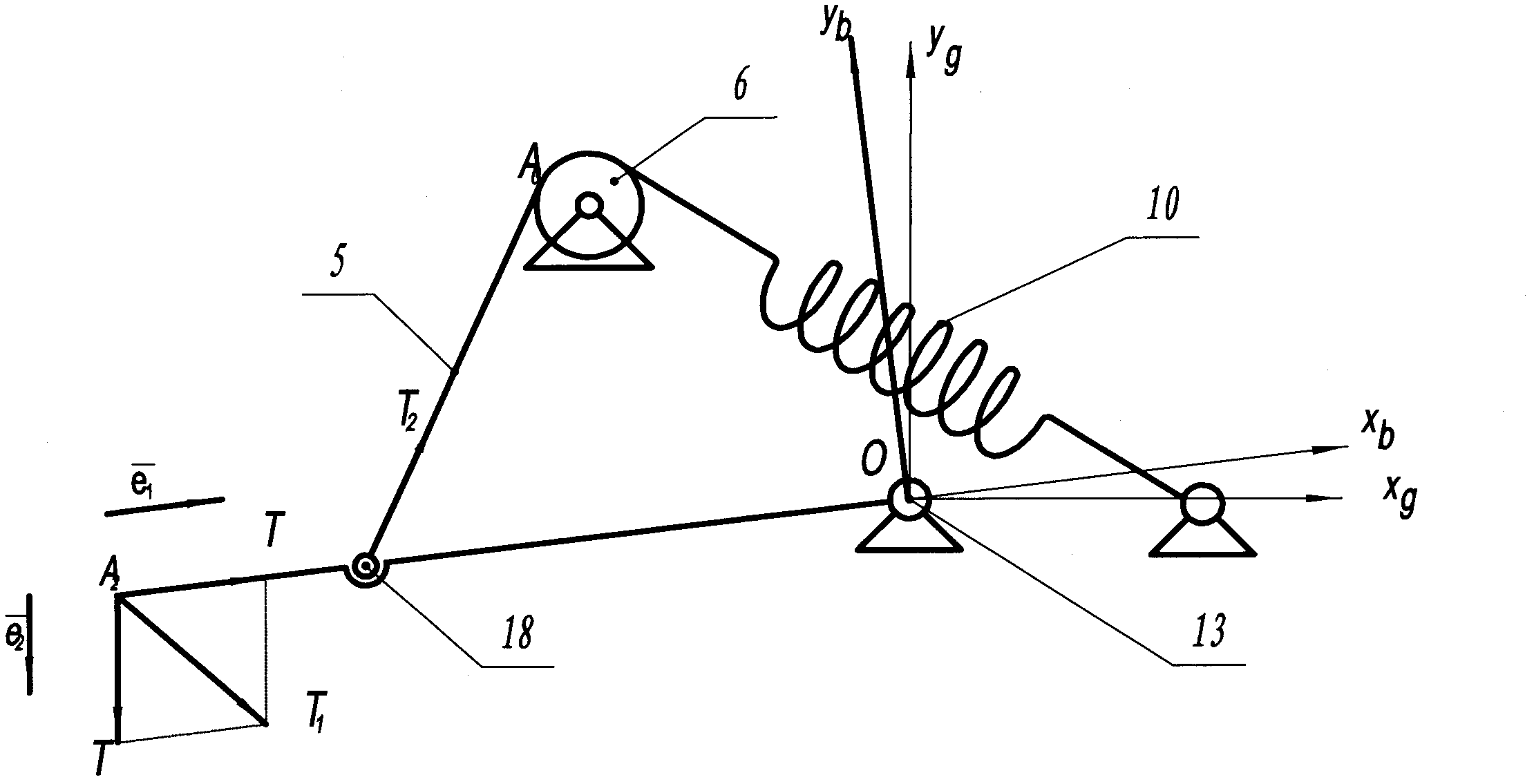

[0032] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, detailed description is as follows:

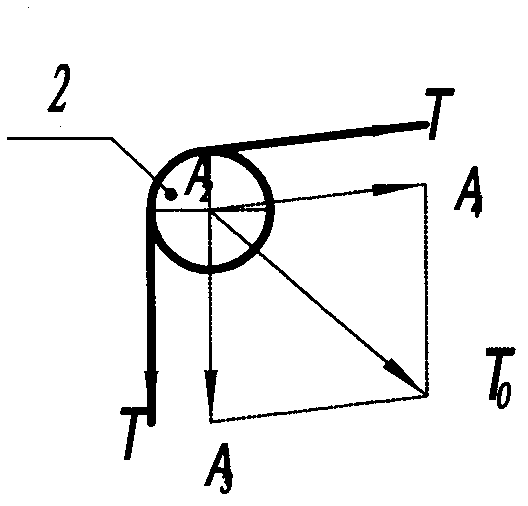

[0033] first as figure 1 As shown, it is a schematic diagram of a sling-type low-gravity simulated tension control buffer mechanism, wherein one end of the swing rod 4 is movably connected with the axis of the balance wheel 2 through a rolling bearing, so that the balance wheel 2 can rotate around its axis; the swing rod The other end of 4 is flexibly connected with the axis of the reel 3 through a rolling bearing, so that the reel 3 can rotate around its axis.

[0034] One end of the sling 1 is wound on the drum 3 , and the other end of the sling 1 passes through the wheel groove of the balance wheel 2 so as to be connected with the workpiece 20 requiring controlled tension. The sling 1 can be hinged to the center of gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com