Method for detecting horizontal equivalent stiffness of rubber shock insulation support

A technology of rubber shock-isolation bearing and equivalent stiffness, which is applied in the field of effective stiffness, to achieve the effect of simplification of test equipment and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

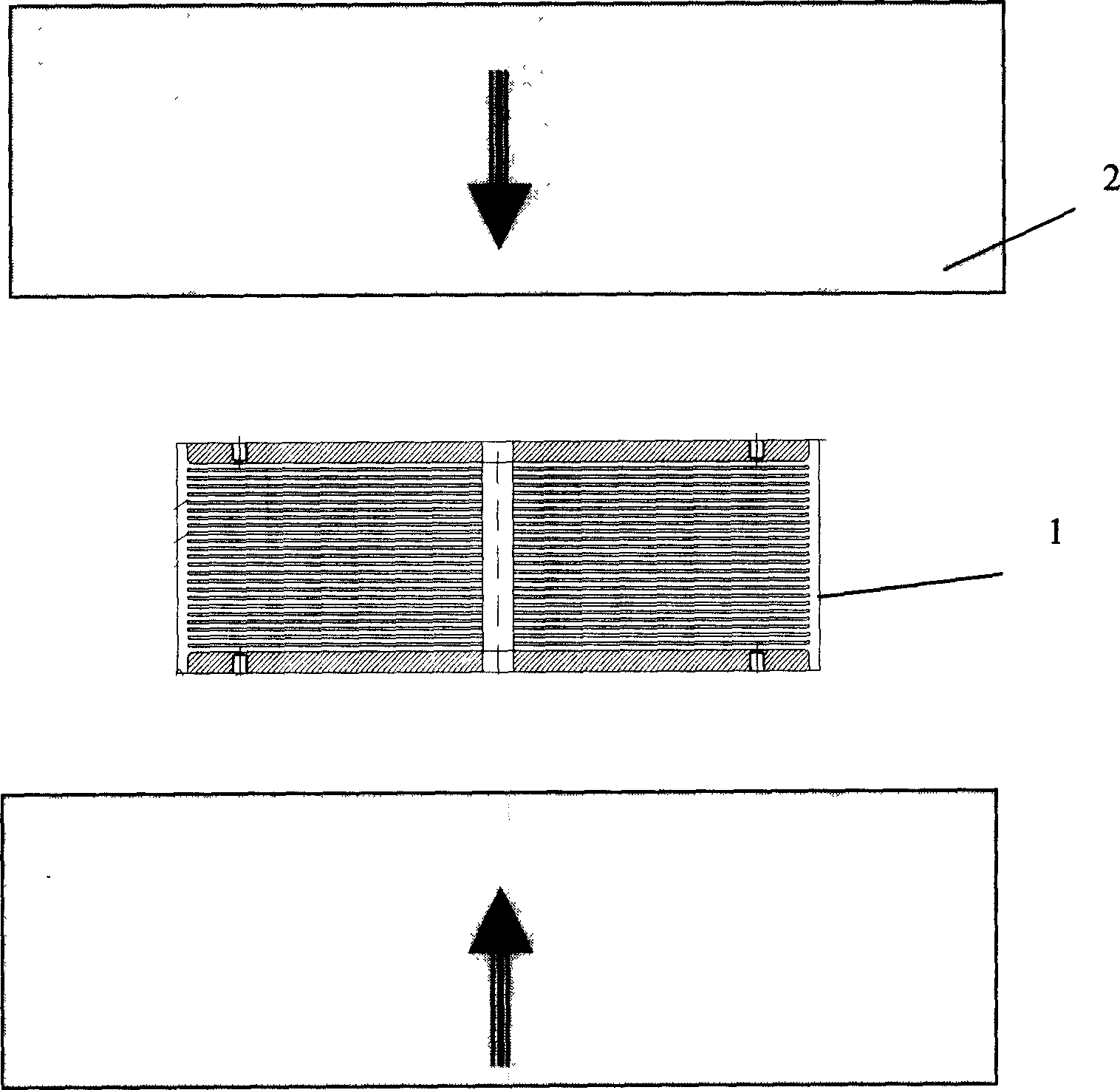

[0011] exist figure 1 In the experiment, the test body 1 of the rubber seismic isolation bearing under test is placed in the loading device 2, and a vertical pressure is applied to the rubber seismic isolation bearing. When the compressive stress reaches the set value, continue to apply pressure to the maximum vertical compressive stress. Then it is unloaded to the vertical compressive stress, and the corresponding deformation difference between the maximum load point and the minimum load point is measured.

[0012] Repeated loading and unloading tests, take the ratio of the force difference between the maximum load point and the minimum load point and the corresponding deformation difference between the maximum load point and the minimum load point as the vertical stiffness of the rubber isolation bearing, according to the measured vertical stiffness value and then calculate the horizontal stiffness value of the tested test body.

[0013] For example, to test the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com