Pneumatic elastic mechanical characteristic analytical method of hypersonic speed aircraft in thermal environment

A kind of aeroelasticity and hypersonic technology, applied in the direction of instruments, special data processing applications, image data processing, etc., can solve the problems of limited scope of use, heavy workload, complex calculation process, etc., to achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

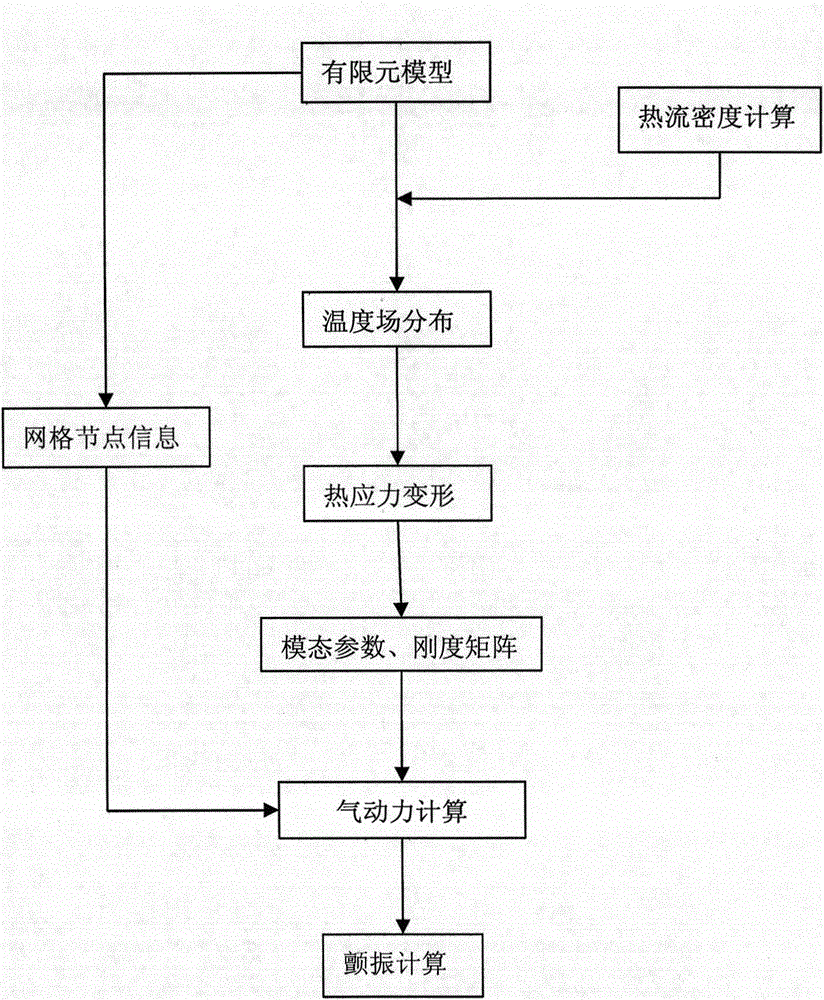

[0122] Embodiment of the method: Taking the analysis of the aeroelastic integration of a certain hypersonic vehicle as an example, and aiming at the basic flow diagram of a method for analyzing the aeroelastic properties of a hypersonic vehicle in a thermal environment, the schematic diagram is as follows figure 1 As shown, it illustrates the specific implementation method of analyzing the aeroelastic performance of a hypersonic vehicle by using an analysis method for the aeroelastic properties of a hypersonic vehicle in a thermal environment.

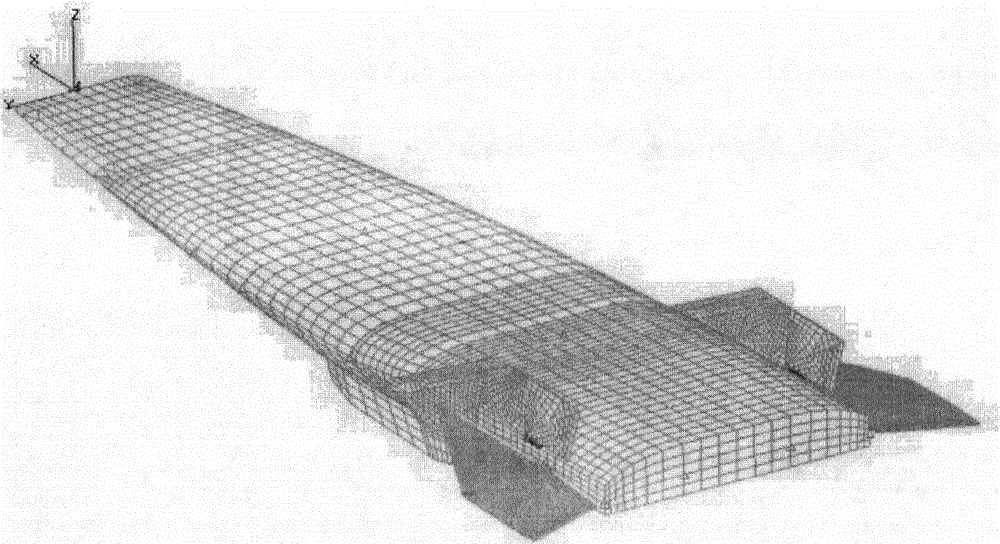

[0123] (1) Establish the overall geometric model and finite element model of the hypersonic vehicle, including the following:

[0124] (a) Based on the actual size profile and layout of a certain type of hypersonic vehicle, establish the geometric model of the whole aircraft in the 3D modeling software CATIA. The geometric model adopts the shape of the 2D lifting body that is conducive to the integrated layout design of the fuselage and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com