Design method for damping coefficient of end longitudinal shock absorbers of high-speed railway vehicle body

A technology of longitudinal, high-speed rail at the end, applied in the directions of instruments, calculations, mechanical equipment, etc., can solve problems such as theoretical design methods without a given system, and difficulties in dynamic analysis and calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

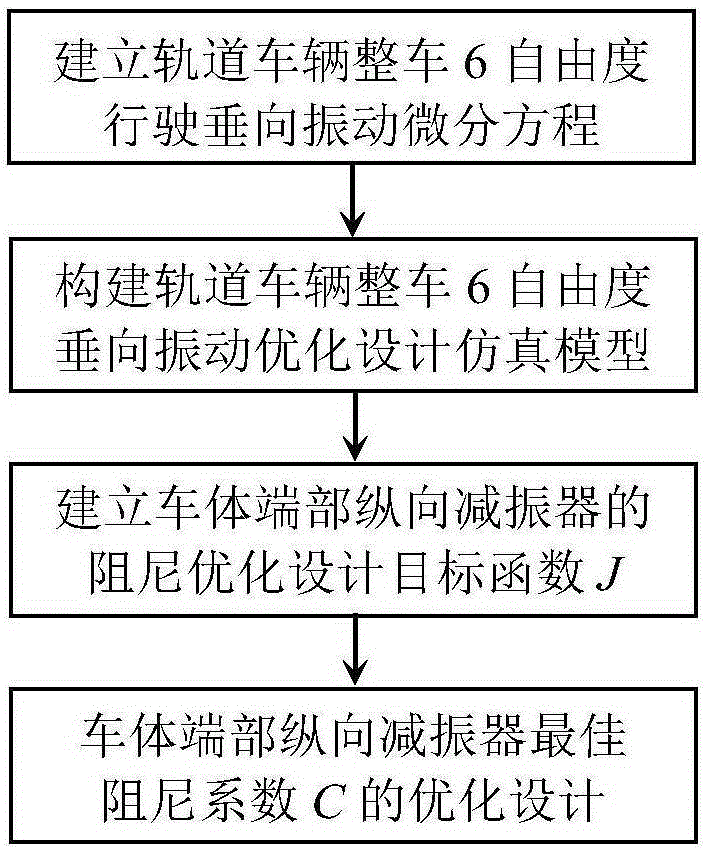

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be further described in detail through an embodiment below.

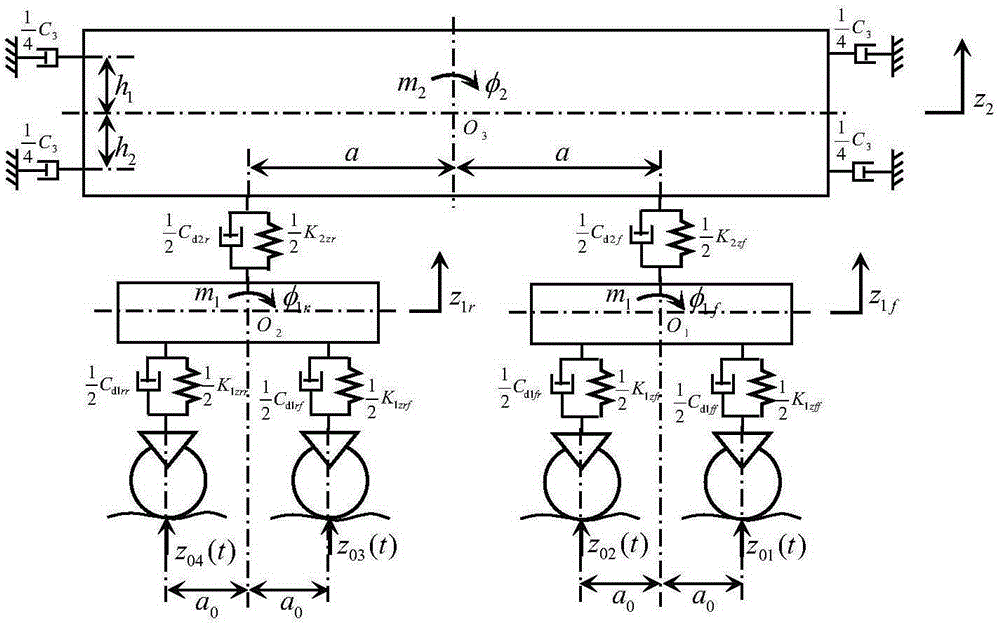

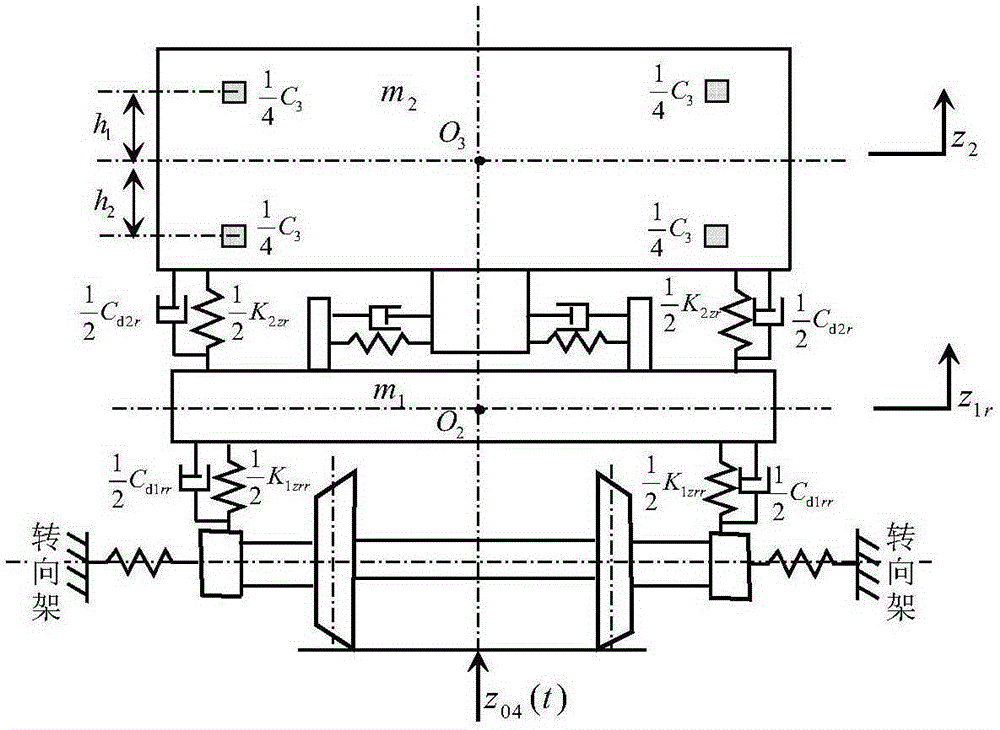

[0031] Four longitudinal shock absorbers at the end of the car body are installed between two adjacent car bodies of a high-speed rail vehicle, that is, n=4, and the mass of a single car body is m 2 =63966kg, nodding moment of inertia J 2φ =2887500kg.m 2 ; Mass of each bogie frame m 1 =2758kg, nodding moment of inertia J 1φ =2222kg.m 2 ;The vertical equivalent stiffness K of the front suspension of the front bogie1zff =2.74×10 6 N / m, vertical equivalent damping C d1ff =28.3kN.s / m, the vertical equivalent stiffness K of the primary rear suspension of the front bogie 1zfr =2.74×10 6 N / m, vertical equivalent damping C d1fr =28.3kN.s / m; The vertical equivalent stiffness K of the primary front suspension of the rear bogie 1zrf =2.74×10 6 N / m, vertical equivalent damping C d1rf =28.3kN.s / m, the vertical equivalent stiffness K of the primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com