Patents

Literature

34results about How to "Elimination method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

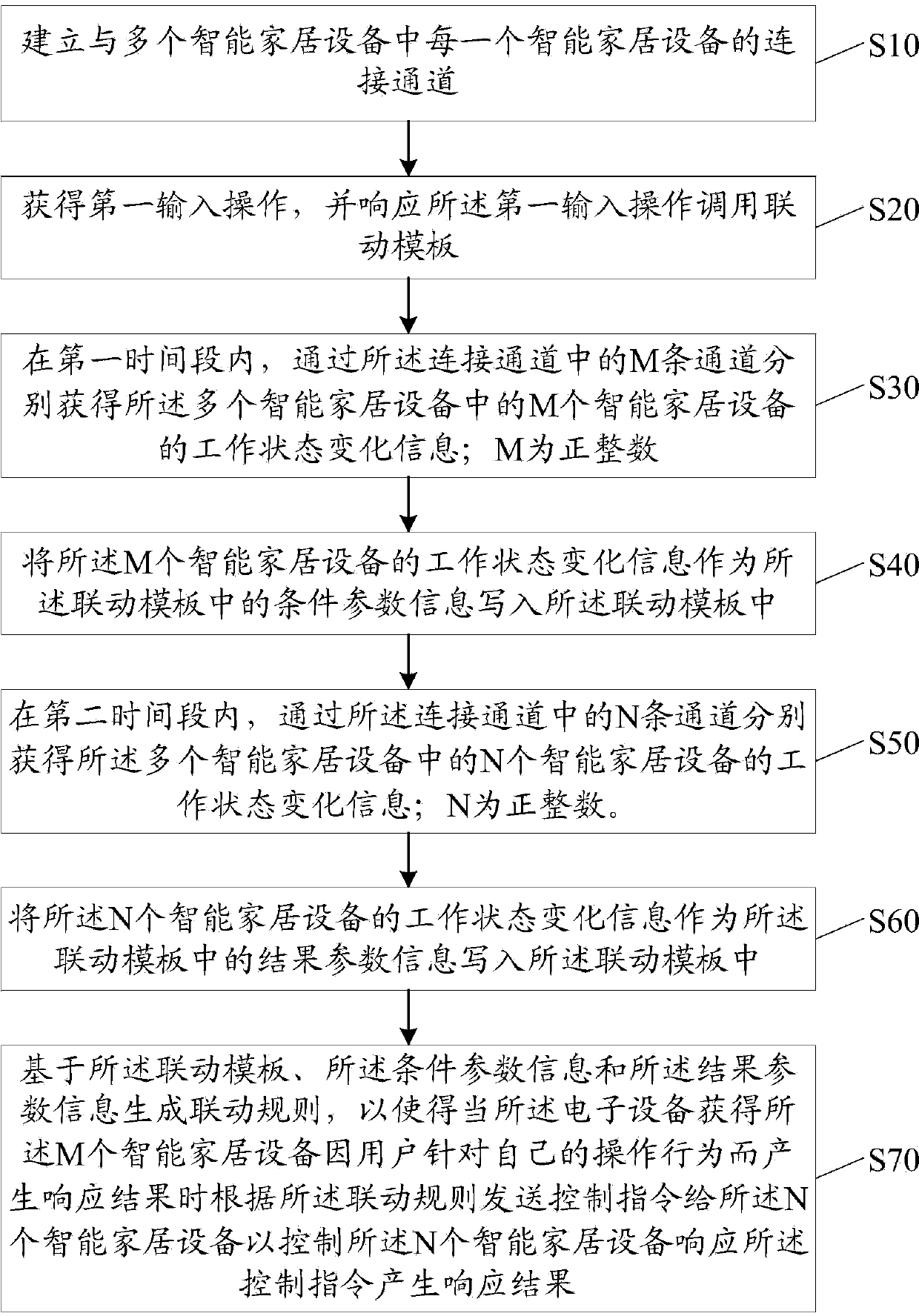

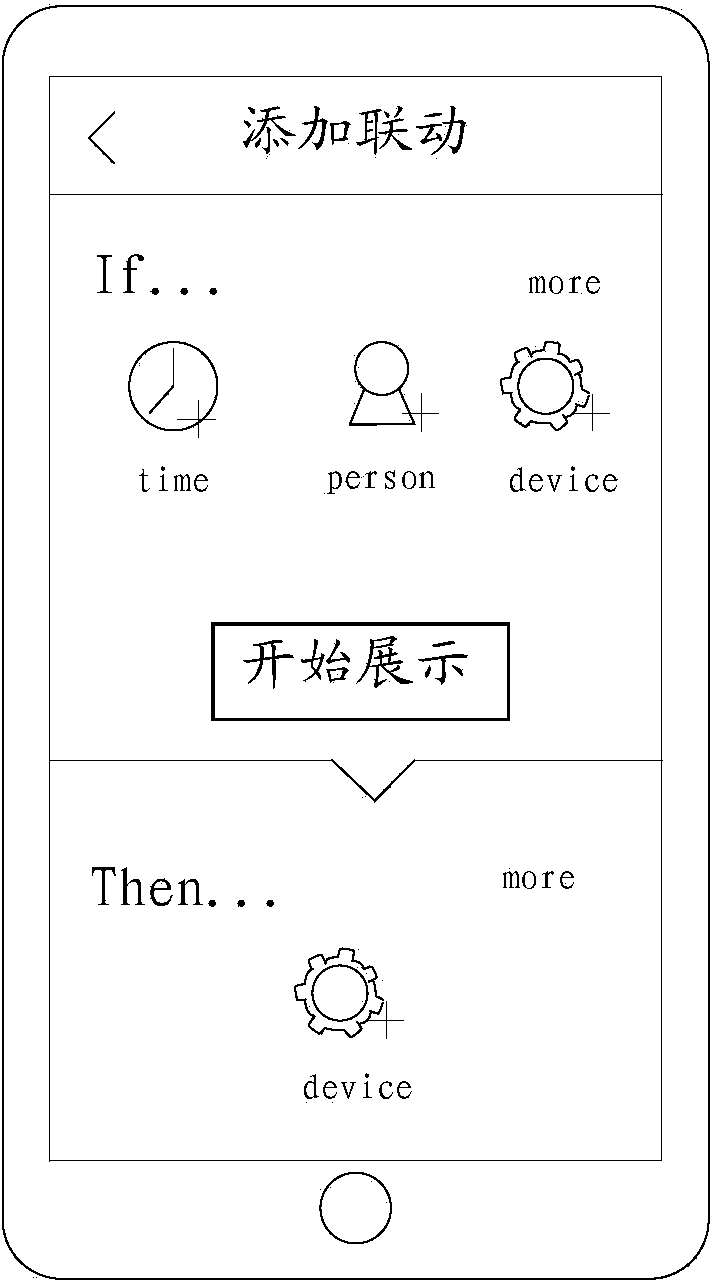

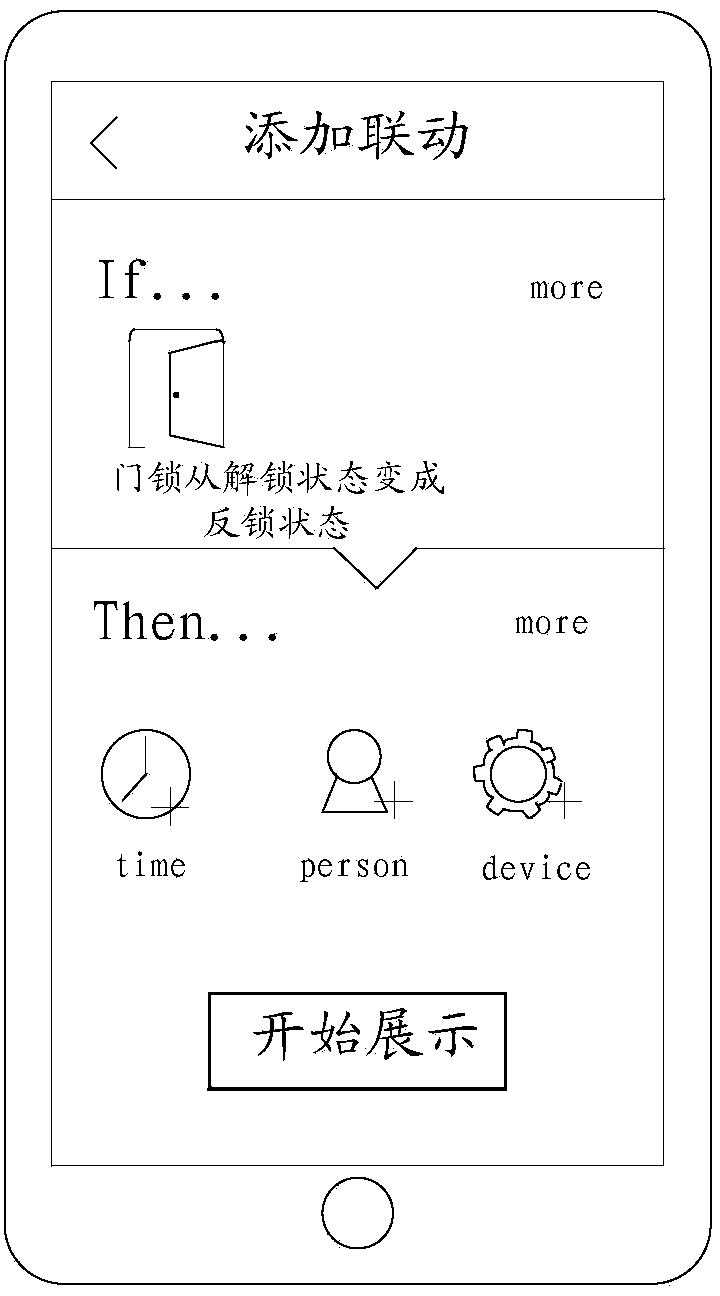

Information processing method and electronic device

ActiveCN104216379AImplement associated responsesElimination methodComputer controlTotal factory controlComputer hardwareInformation processing

The invention discloses an information processing method and an electronic device. The method includes the steps: establishing a connecting channel connected with each smart home device of a plurality of smart home devices; obtaining a first input operation and responding to the first input operation to call a linkage template; obtaining work status change information of the smart home devices with the number of M of a plurality of the smart home devices in the first period of time; taking the work status change information of the smart home devices with the number of M as condition parameter information of the linkage template to be written in the linkage template; respectively obtaining the work status change information of the smart home devices with the number of N of a plurality of the smart home devices in the second period of time; taking the work status change information of the smart home devices with the number of N as condition parameter information of the linkage template to be written in the linkage template; generating a linkage rule based on the linkage temple, the condition parameter information and result parameter information.

Owner:LENOVO (BEIJING) CO LTD

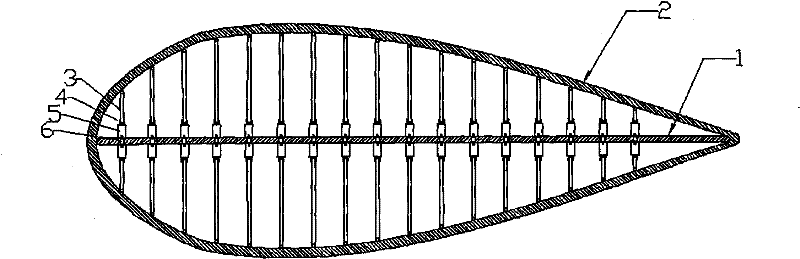

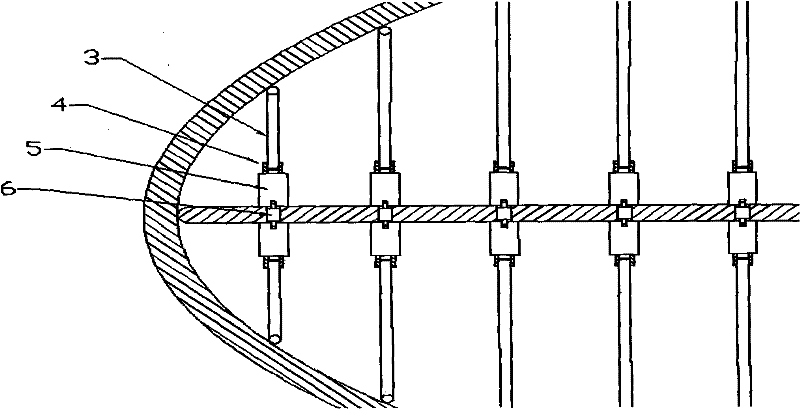

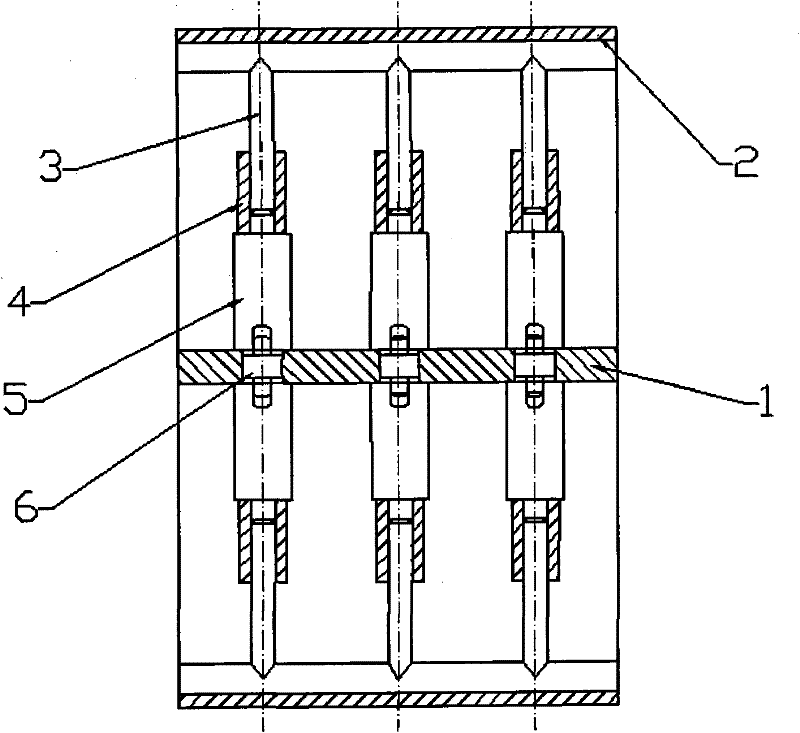

Device for adjusting wing surface of wing wind tunnel blowing model and adjustment method

InactiveCN102221444AEliminate theoretical flawsElimination methodAerodynamic testingControl signalActuator

The invention relates to a device for adjusting the wing surface of a wing wind tunnel blowing model and an adjustment method. In the device provided by the invention, the width of a support base is equal to the chordwise length of the wing wind tunnel blowing model; the length of the support base is equal to the spanwise length of the wing wind tunnel blowing model; multiple rows of actuators are distributed along the length direction of the support base; each row of actuators comprises multiple actuators; each actuator is respectively positioned on each design point of the wing and corresponds to the horizontal ordinates of each design point of the wing; the actuators are installed on the upper surface and lower surface of the support base in pairs; and the actuators in the same column on the same surface are connected through a data line and used for receiving the same control signals and carrying out the equal amplitude displacement. The invention provides a convenient and practical wing surface deformation adjusting mechanism for the wing surface deformation based on the wing shape design of a wind tunnel experiment, establishes a high-efficiency wing shape optimization design system by means of the environment and conditions of the wind tunnel experiment and provides different wing shape results for the engineering actually, thereby improving the design level and design efficiency of the existing wing shape.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

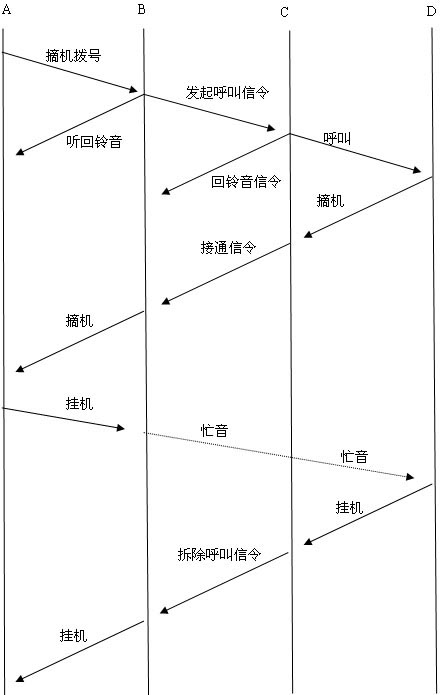

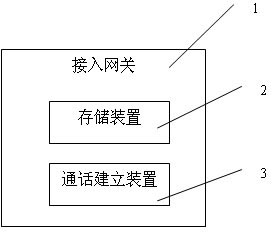

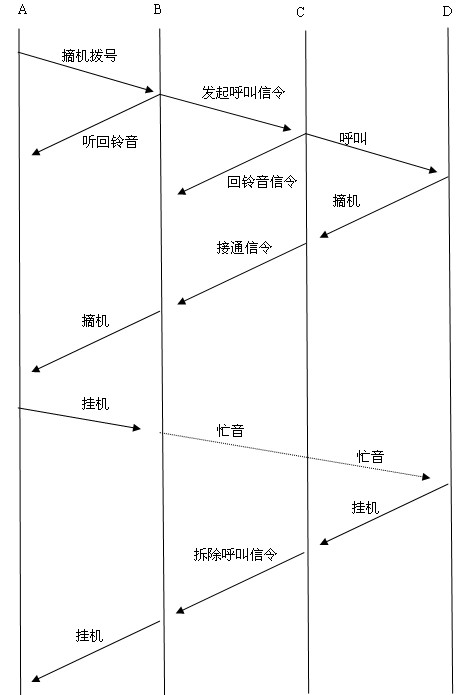

Method, system and gateway for seamlessly setting up call by using voice over internet protocol (VoIP) technique

ActiveCN102131013AEliminate usabilityElimination methodInterconnection arrangementsInternet protocol suiteRing back tone

The invention discloses a method for seamlessly setting up a call. The method is as follows: a caller initiates the call, and a called number corresponding to the caller is set in an access gateway in advance; when the access gateway detects that the caller is in an incoming state, the call is initiated for the called number; and during the period of waiting for connection, the caller is in a state of listening a ring-back tone all the time until the incoming call is hooked off, then the access gateway informs the caller of hooking off, so that the call is set up between the caller and the incoming call. The invention also discloses a system and access gateway for seamlessly setting up a call. Under the conditions that extra cost is not added and brand new network elements are introduced,the differences of use habits and dial nodes are caused by a voice over internet protocol (VoIP) technique so that an operator can provides service for any person at any position without limitation of space and time; and simultaneously, an exterior person and the operator do not feel the existence of VoIP, thereby achieving the purposes of saving money and ensuring convenience.

Owner:上海钜成宽度电子科技有限公司

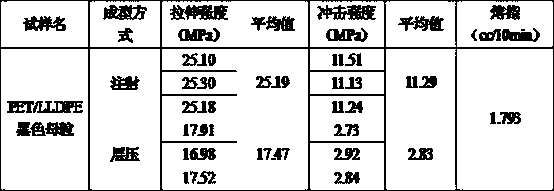

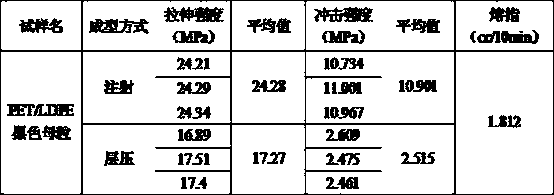

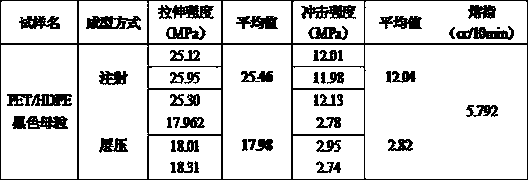

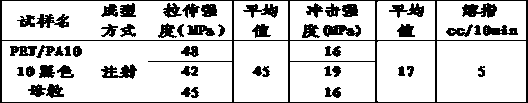

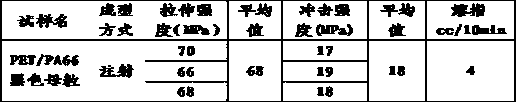

Method for processing PET/PA ferrous alloy color masterbatch by chemically depolymerizing waste polyester textiles

InactiveCN110256699AElimination methodAvoid secondary contaminationPlastic recyclingPolyesterMasterbatch

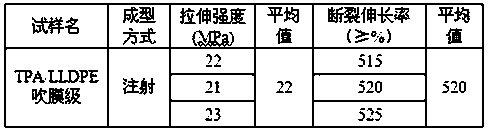

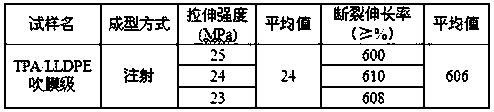

The invention provides a method for processing PET / PA ferrous alloy color masterbatch by chemically depolymerizing waste polyester textiles. The method is characterized by comprising the following steps: preparing components including, by weight, 20 parts of PET, 40 parts of blown-film-grade LDPE, 30 parts of black carbon black and 10 parts of a compatibilizer; uniformly mixing the prepared components; and performing extrusion and granulation so as to obtain PET / LDPE ferrous alloy blown-film-type color masterbatch. Or the method comprises the following steps: preparing components including, by weight, 30 parts of PET, 30 parts of extrusion-grade LLDPE, 30 parts of black carbon black and 10 parts of a compatibilizer; uniformly mixing the prepared components; and performing extrusion and granulation so as to obtain PET / LLDPE ferrous alloy extrusion-type color masterbatch. Or the method comprises the following steps: preparing components including, by weight, 40 parts of PET, 20 parts of injection-grade HDPE, 30 parts of black carbon black and 10 parts of a compatibilizer; uniformly mixing the prepared components; and performing extrusion and granulation so as to obtain PET / HDPE ferrous alloy injection-type color masterbatch.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

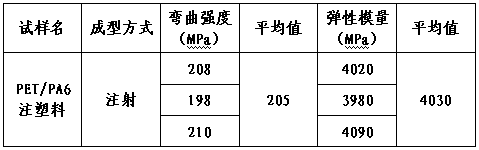

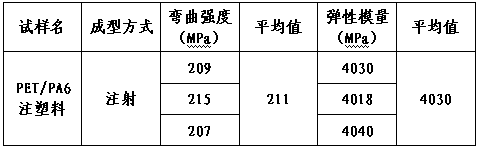

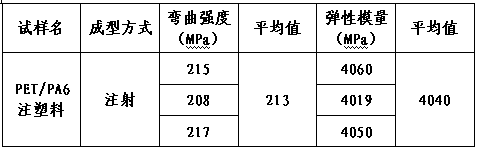

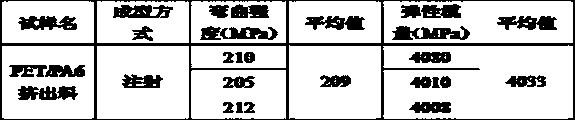

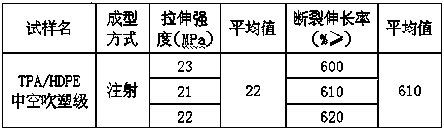

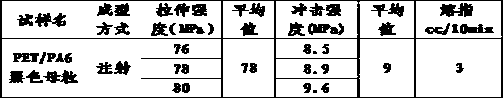

Method for depolymerizing, purifying and polymerizing PET by using waste polyester textiles and adding injection-molding PA6 for modification

InactiveCN110256822AElimination methodAvoid secondary contaminationPlastic recyclingPolyesterGlycerol

The invention discloses a method for preparing a novel alloy injection molding material by chemically depolymerizing, purifying and polymerizing PET by using waste polyester textiles in our plant and adding injection-molding PA6 material for modification. The method comprises the following steps: depolymerizing, filtering, decolorizing and purifying waste polyester textiles by using glycerol residues heated to 260-280 DEG C, then polymerizing the material into PET, adding auxiliaries such as a compatilizer, adding injection-molding PA6 material in a certain proportion, uniformly mixing the components and performing extrusive granulation on the mixture to obtain the special PET / PA6 injection molding alloy new material.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

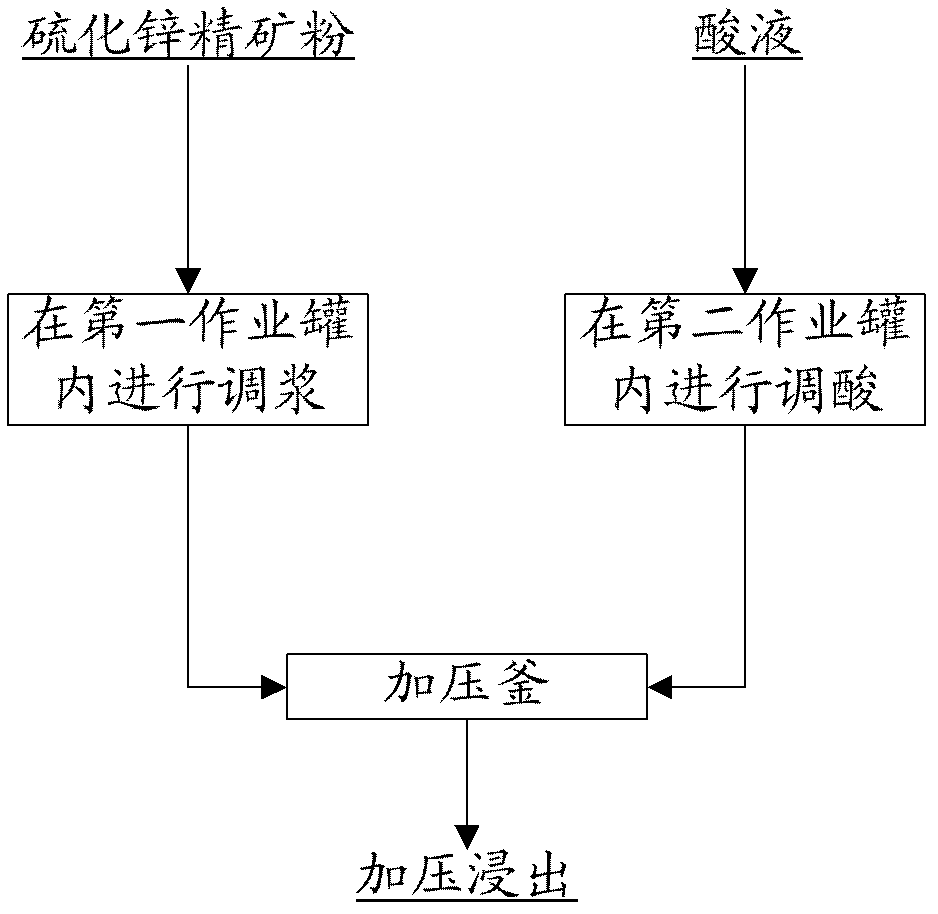

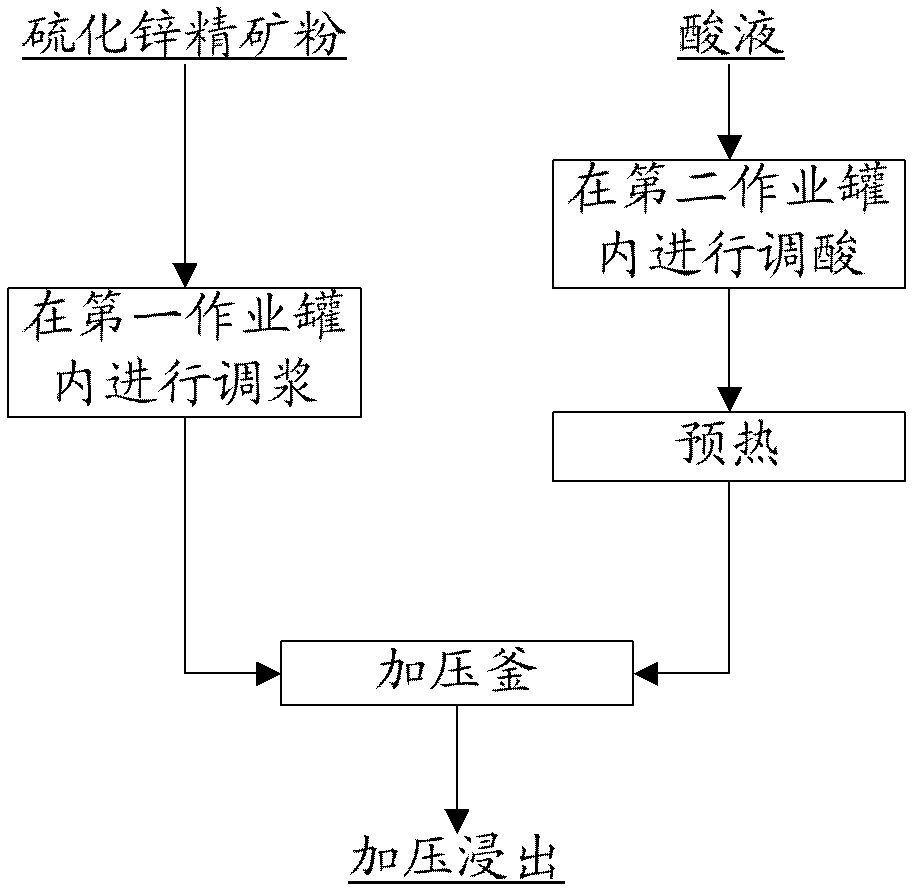

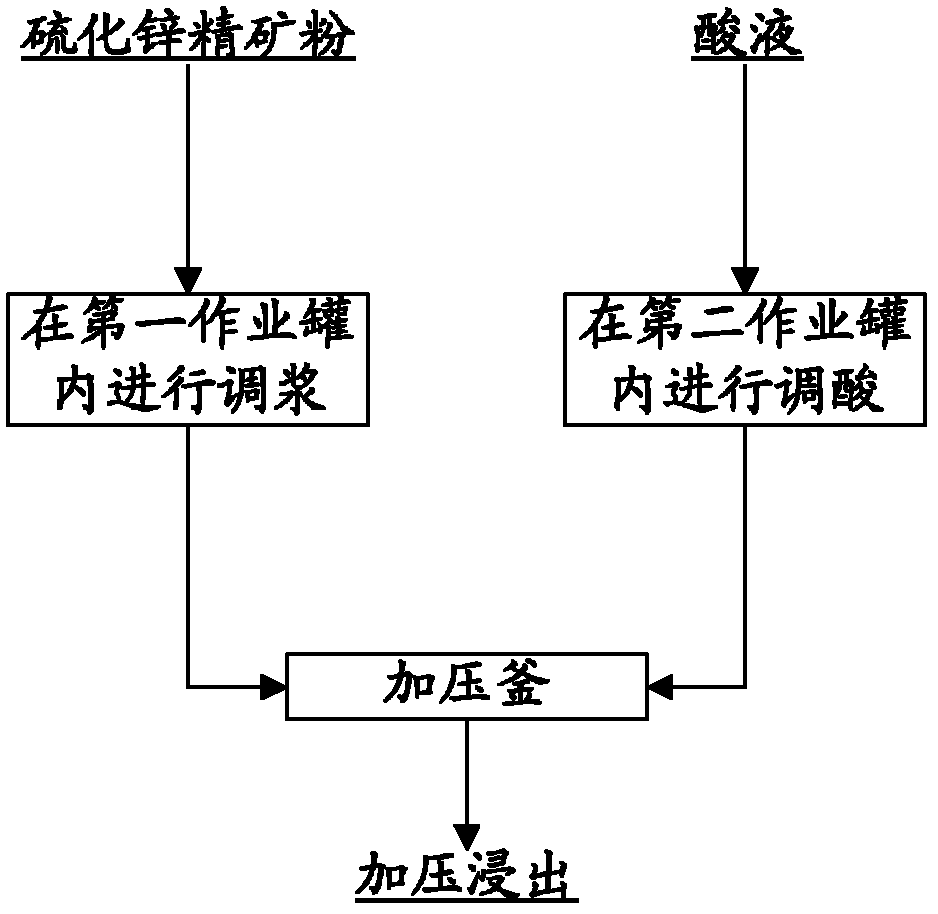

Method for treating zinc sulfide concentrate powder

The invention discloses a method for treating zinc sulfide concentrate powder. The method comprises the steps of: a) carrying out size mixing on the zinc sulfide concentrate powder in a first operation tank to obtain slurry; b) adjusting acid liquor in a second operation tank so as to obtain material acid; and c) respectively adding the slurry obtained in the step a) and the material acid obtained in the step b) into an autoclave for pressure leaching. The method for treating the zinc sulfide concentrate powder according to the embodiment of the invention is simple in principle, high in feasibility and remarkable in effects.

Owner:YUNNAN METALLURGICAL GROUP +1

Method for preparing crude diisooctyl terephthalate by cracking polyester waste textiles

InactiveCN110092718AElimination methodAvoid secondary contaminationPreparation by ester-hydroxy reactionOrganic compound preparationPolyesterTextile

Polyester waste textiles are heated and dissolved in ethylene glycol, the obtained solution is filtered to remove dregs, and isooctyl alcohol is added to achieve esterification and exchange out the ethylene glycol in order to form crude diisooctyl terephthalate.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

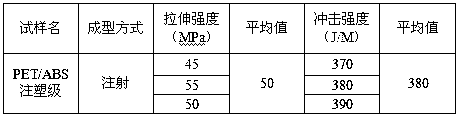

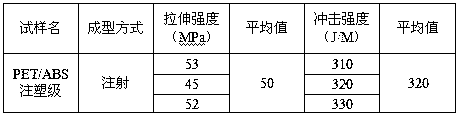

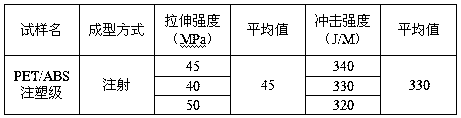

Modification method through depolymerization, purification and polymerization of PET from waste polyester textiles and addition of injection-molding ABS

The invention discloses a modification method for preparing a novel special alloy material used for injection molding through chemical depolymerization, purification and polymerization of PET from waste polyester textiles and addition of an injection-molding-grade ABS material in a plant. The method provided by the invention comprises the following steps: heating glycerin residue to 260 to 280 DEG C, then depolymerizing the waste polyester textiles with heated glycerin residue, carrying out filtering, decolorizing and purifying so as to polymerize PET, then adding modifying auxiliary agents like a compatibilizing agent, adding the injection-molding-grade ABS material in a certain proportion, carrying out uniform mixing, and carrying out extrusion granulation so as to obtain the novel special PET / ABS alloy material used for injection molding.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing dibutyl terephthalate through waste polyester fabric depolymerization purification+butanol

InactiveCN110423199AElimination methodAvoid secondary contaminationOrganic compound preparationCarboxylic acid esters preparationPolymer scienceDepolymerization

The invention discloses a method for preparing dibutyl terephthalate through waste polyester fabric depolymerization purification+butanol. A purified terephthalic acid monomer is prepared from a wastepolyester fabric through depolymerization and distillation purification, and butanol is added for esterification, and thus dibutyl terephthalate is prepared.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Chemical reduction method for preparing PBT raw material from Dacron domestic textile fabric leftover materials

The invention discloses a chemical reduction method for preparing PBT raw material from Dacron domestic textile fabric leftover materials. After the Dacron domestic textile fabric leftover materials are heated and dissolved by using butanediol, filtration and then decoloration are carried out, BHBT is purified, and a catalyst is added to polymerize PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing PBT raw material by chemical reduction of PET waste bottle material

The invention provides a method for preparing a PBT raw material by chemical reduction of a PET waste bottle material. The method comprises the following steps: heating and melting the PET waste bottle material by using butanediol, performing filtration, performing decolorization, performing purification, adding a catalyst, and performing polymerization to form PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

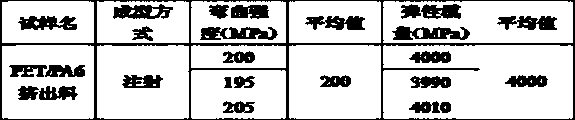

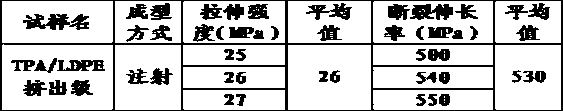

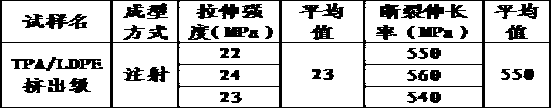

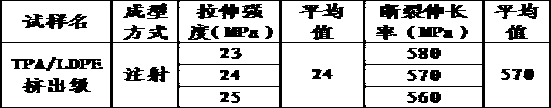

Method for modifying PET obtained by depolymerization of polyester waste textiles, purification and polymerization and extrusion PA6

The invention discloses a method for modifying PET obtained by chemical depolymerization of polyester waste textiles, purification and polymerization and an extrusion-grade PA6 material to form an alloy extrusion novel material in Central Plastic Union New Material Technology (Hubei) Co., Ltd. The method comprises the following steps: performing depolymerization on the polyester waste textiles byusing glycerin residues heated to 260-280 DEG C, performing filtration, performing decolorization, performing purification, performing polymerization to form the PET, adding auxiliary agents such as acompatibilizer, adding a certain proportion of the extrusion-grade PA6 material, performing uniform mixing, and performing extrusion granulation to obtain the PET and PA6 extrusion special alloy novel material.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

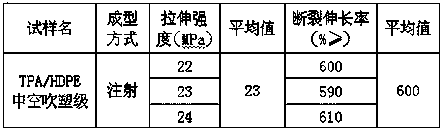

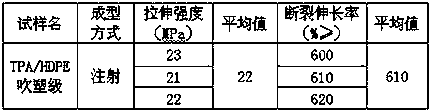

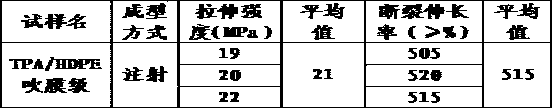

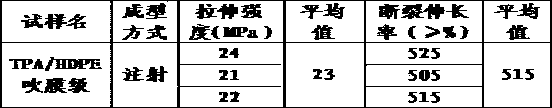

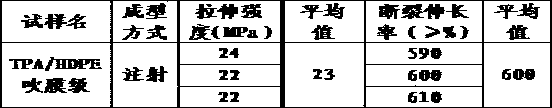

Method for modifying waste terylene textiles by depolymerizing and purifying TPA and adding hollow HDPE

The invention discloses a method for modifying waste terylene textiles into a new hollow blow molding alloy material by chemically depolymerizing and purifying TPA and adding a hollow blow molding grade HDPE material in factories. The method comprises the steps: depolymerizing, filtering, decoloring and purifying the waste polyester textiles by glycerol residues heated to 260-280 DEG C to obtain TPA, adding a compatilizer and other modification aids, adding a certain proportion of hollow blow molding grade HDPE material, uniformly mixing, extruding and granulating to obtain the special new alloy material for TPA / HDPE hollow blow molding.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method used for reduction preparation of PBT raw material from PET waste sheet materials

InactiveCN110092894AElimination methodAvoid secondary contaminationPlastic recyclingMaterials scienceButylene Glycols

The invention discloses a method used for reduction preparation of PBT raw material from PET waste sheet materials. According to the method, PET waste sheet material is subjected to heating dissolvingwith butylene glycol, and filtering, decolouring, purifying, and catalyst adding polymerization are carried out so as to obtain PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

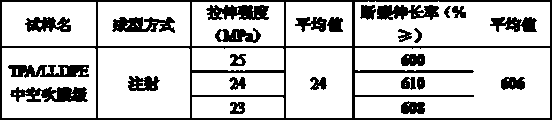

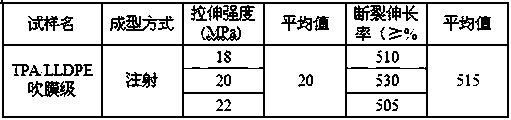

Method for performing depolymerization, purification of TPA (terephthalic acid) and hollow LLDPE (linear low density polyethylene) modification on polyester waste textiles

InactiveCN110229410AElimination methodAvoid secondary contaminationPreparation from carboxylic acid esters/lactonesCarboxylic compound separation/purificationLow-density polyethyleneLinear low-density polyethylene

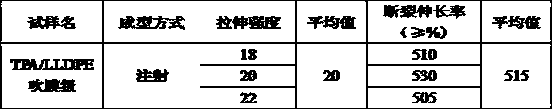

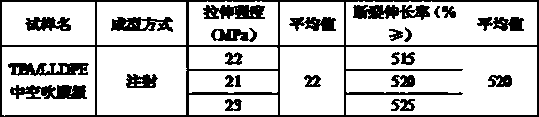

The invention discloses a method for modifying polyester waste textiles into new alloy materials special for hollow blow molding by performing chemical depolymerization and purification of TPA (terephthalic acid) and adding hollow blow molding grade LLDPE (linear low density polyethylene) materials. The method comprises the following steps: performing depolymerization, filtration, decoloration andpurification on the polyester waste textiles with glycerin residues heated to a temperature of 260-280 DEG C so as to obtain TPA, adding a compatilizer and other modification agents, adding hollow blow molding grade LLDPE materials of a certain ratio to be uniformly mixed, and performing extruded granulation so as to obtain the TPA / LLDPE new alloy material special for hollow blow molding.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for processing PET/PA ferrous alloy color masterbatch by chemically depolymerizing waste polyester textiles

InactiveCN110256842AElimination methodAvoid secondary contaminationPlastic recyclingPolyesterMasterbatch

The invention discloses a method for processing PET / PA ferrous alloy color masterbatch by chemically depolymerizing waste polyester textiles. The method comprises the following steps: depolymerizing waste polyester textiles with glycerol residues which have been heated to 260-280 DEG C, and completely filtering out dreg in a solution; adding black carbon black, a compatibilizer and the like, uniformly mixing the above substances with raw materials of different models including PA6, PA66 and PA1010; and performing extrusion and granulation to the special ferrous alloy color masterbatch for PET, PA6, PA66 and PA1010.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for depolymerizing and purifying TPA by using waste polyester textiles and adding film-blowing LDPE for modification

InactiveCN110256748AElimination methodAvoid secondary contaminationPreparation from carboxylic acid esters/lactonesCarboxylic compound separation/purificationPolyesterGlycerol

The invention discloses a method for preparing a special alloy new material for extrusion by chemically depolymerizing and purifying TPA and adding an extrusion-grade LDPE material by using waste polyester textiles in our plant. The method comprises the following steps: depolymerizing, filtering, decoloring and purifying waste polyester textiles by using glycerol residues heated to 260-280 DEG C to obtain TPA, adding a compatilizer and other modification aids, adding an extrusion-grade LDPE material in a certain proportion, uniformly mixing the components and performing extrusive granulation on the mixture to obtain the special TPA / LDPE extrusion alloy new material.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

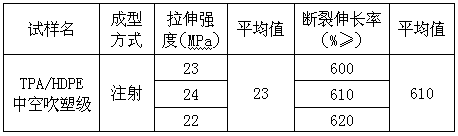

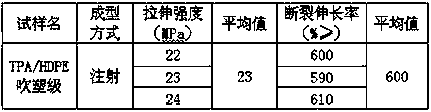

Method for depolymerization purification of TPA by using polyester waste textiles and modifying by adding blow-molding-grade HDPE

InactiveCN110358167AElimination methodAvoid secondary contaminationPreparation from carboxylic acid esters/lactonesCarboxylic compound separation/purificationPolyesterBlow molding

The invention discloses a method for carrying out chemical depolymerization purification on TPA by using polyester waste textiles and modifying by adding a blow-molding-grade HDPE material to obtain anew alloy blow molding material. According to the method, polyester waste textiles are subjected to depolymerization, filtration, decolorization and purification by using glycerin residue heated to atemperature of 260-280 DEG C to form TPA, a compatibilizer and other modification auxiliary agents are added, a blow-molding-grade HDPE material is added according to a certain ratio, and uniform mixing and extruding granulation are sequentially performed to obtain the new special alloy material for TPA / HDPE blow molding.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing dioctyl terephthalate by depolymerizing and purifying waste polyester textiles and adding octanol

InactiveCN110423195AElimination methodAvoid secondary contaminationPreparation by ester-hydroxy reactionOrganic compound preparationChemistryTextile

According to the invention, waste terylene textiles are depolymerized, distilling purification is carried out to obtain purified terephthalic acid monomers, and octanol is added for esterification, sothat dioctyl terephthalate is obtained.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing PBT raw material by chemical reduction of polyester clothing leftovers

InactiveCN110105206AElimination methodAvoid secondary contaminationOrganic compound preparationCarboxylic acid esters preparationPolyesterFiltration

The invention relates to a method for preparing a PBT raw material by chemical reduction of polyester clothing leftovers. The polyester clothing leftovers are heated and melted with butanediol, decolorization is carried out after filtration, purification is carried out to obtain BHBT, and a catalyst is added for polymerization to obtain PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Modification method through depolymerization and purification of TPA from waste polyester textiles and addition of film-blowing LLDPE

InactiveCN110272578AElimination methodAvoid secondary contaminationPreparation from carboxylic acid esters/lactonesCarboxylic compound separation/purificationPolyesterDepolymerization

The invention discloses a modification method for preparing a novel special alloy material used for film blowing through chemical depolymerization and purification of TPA from waste polyester textiles and addition of a film-blowing-grade LLDPE material. The method comprises the following steps: heating glycerin residue to 260 to 280 DEG C, depolymerizing the waste polyester textiles with heated glycerin residue, carrying out filtering, decolorizing and purifying so as to obtain TPA, adding modifying auxiliary agents like a compatibilizing agent, then adding the film-blowing-grade LLDPE material in a certain proportion, and carrying out extrusion granulation so as to obtain a novel special TPA / LLDPE alloy material used for film blowing.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing PBT raw material through chemical reduction of PET wastes

InactiveCN110156969AElimination methodAvoid secondary contaminationPreparation by ester-hydroxy reactionChemical reductionButylene Glycols

The invention relates to a method for preparing a PBT raw material through chemical reduction of PET wastes. The method comprises the steps of dissolving the PET wastes with butylene glycol through heating, then, carrying out filtering, then, carrying out decoloring, carrying out purifying to obtain BHBT, and adding a catalyst to synthesize PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing PBT through chemical reduction of waste dacron textiles

InactiveCN110117224AElimination methodAvoid secondary contaminationOrganic compound preparationCarboxylic acid esters preparationButanediolChemical reduction

The invention relates to a method for preparing PBT through chemical reduction of waste dacron textiles. The method comprises the steps of heating and dissolving the waste dacron textiles with butanediol, performing filtering and decolorizing, then conducting purification to obtain BHBT, and adding a catalyst to polymerize PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing crude diisobutyl terephthalate by pyrolysis of polyester waste textiles

InactiveCN110204439AElimination methodAvoid secondary contaminationPreparation by ester-hydroxy reactionIsobutanolPolyester

The invention discloses a method for preparing crude diisobutyl terephthalate by pyrolysis of polyester waste textiles. The polyester waste textiles are dissolved by ethylene glycol through heating, dregs are filtered out, isobutanol is added for esterification, and the ethylene glycol is exchanged to form the crude diisobutyl terephthalate.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing PBT raw material through chemical reduction of polyester waste fibers

InactiveCN110105205AElimination methodAvoid secondary contaminationOrganic compound preparationCarboxylic acid esters preparationPolyesterFiber

The invention discloses a method for preparing a PBT raw material through chemical reduction of polyester waste fibers. Firstly, the polyester waste fibers are crushed into pieces of 100 mm in size, and the pieces are dissolved with butanediol heated to 220 DEG C.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Method for preparing PBT by chemical reduction of waste PET packaging belts

The invention discloses a method for preparing PBT by chemical reduction of waste PET packaging belts. After the waste PET packaging belts are heated and molten with butanediol, filtration is performed, then decolorization and purification are performed, and a catalyst is added for polymerization to obtain PBT.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

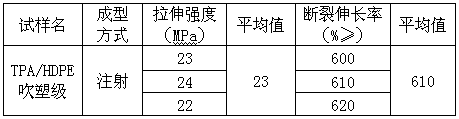

Method for depolymerizing and purifying TPA by using waste polyester textiles and adding film-blowing HDPE for modification

InactiveCN110256749AElimination methodAvoid secondary contaminationPreparation from carboxylic acid esters/lactonesCarboxylic compound separation/purificationPolyesterGlycerol

The invention discloses a method for preparing a novel alloy film blowing material by chemically depolymerizing and purifying TPA from waste polyester textiles and adding a film blowing grade HDPE material for modification in our plant. The method comprises the following steps: depolymerizing, filtering, decoloring and purifying waste polyester textiles by using glycerol residues heated to 260-280 DEG C to obtain TPA, adding a compatilizer and other modification aids, adding a certain proportion of film blowing grade HDPE material, uniformly mixing the components and performing extrusive granulation on the mixture to obtain the special TPA / HDPE film-blowing alloy new material.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

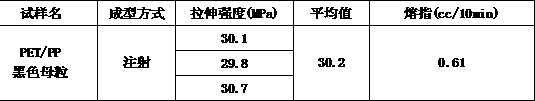

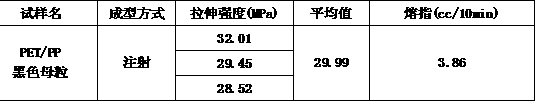

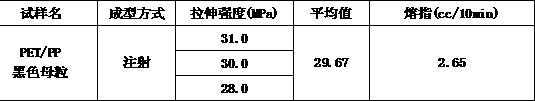

Method for chemically depolymerizing polyester waste textiles to produce PET/PP black alloy color master batches

InactiveCN110092925AElimination methodAvoid secondary contaminationPlastic recyclingPolyesterMasterbatch

The invention discloses a method for chemically depolymerizing polyester waste textiles to produce PET / PP black alloy color master batches. The method comprises the following steps: heated glycerin residues with a temperature of 260-280 DEG C are used to depolymerize the polyester waste textiles, dregs in the obtained solution are filtered out completely, black carbon black, a compatilizer and a PP raw material for film blowing, wire drawing and injection molding of different models are added, and the obtained mixture is uniformly mixed, and undergoes extruding granulation to obtain the special PET and PP black alloy color master batches for film blowing, wire drawing and injection molding.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Fully utilized dacron waste spinning chemical reduction PBT test production line with low energy consumption and no pollution

InactiveCN110333315AElimination methodPreparing sample for investigationTextile testingProduction lineEngineering

The invention discloses a fully utilized dacron waste spinning chemical reduction PBT test production line with low energy consumption and no pollution, which is well designed by technical staffs of our factory according to practical experience summarized in years of practice. The device comprises six parts including alcoholysis dissolving, filtering, decoloration, purification, polymerization andbutanediol recovery devices. The test device is extremely low in energy consumption, and the whole test process absolutely has no exhaust and drainage,

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

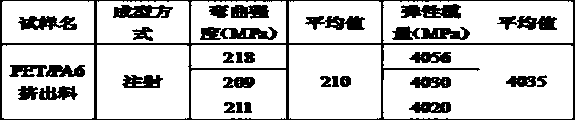

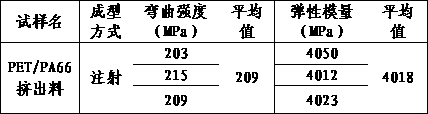

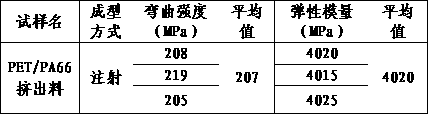

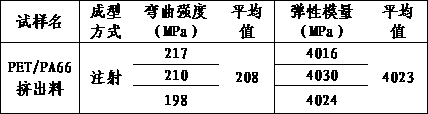

Method for modification via both extrusion-grade PA66 and PET prepared from waste polyester textiles through depolymerization, purification and polymerization

InactiveCN110256820AElimination methodAvoid secondary contaminationPlastic recyclingPolyesterDepolymerization

The invention discloses a method for modifying both an extrusion-grade PA66 material and PET prepared from waste polyester textiles through chemical depolymerization, purification and polymerization so as to prepare a novel extruded alloy material. The method comprises the following steps: subjecting waste polyester textiles to depolymerization, filtration, decolorization and purification with glycerin residues having been heated to 260-280 DEG C, then performing polymerization to form PET, adding a compatibilizer and other additives, then adding a certain proportion of an extrusion-grade PA66 material, carrying out uniform mixing and then performing extrusion and granulation to obtain the novel special PET-PA66 extruded alloy material.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com