Heat exchanger performance test stand

A test bench and heat exchanger technology, applied in the testing of machine/structural components, instruments, material thermal development, etc., can solve the problems of expensive foreign products, unaffordable, and equipment that cannot be found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

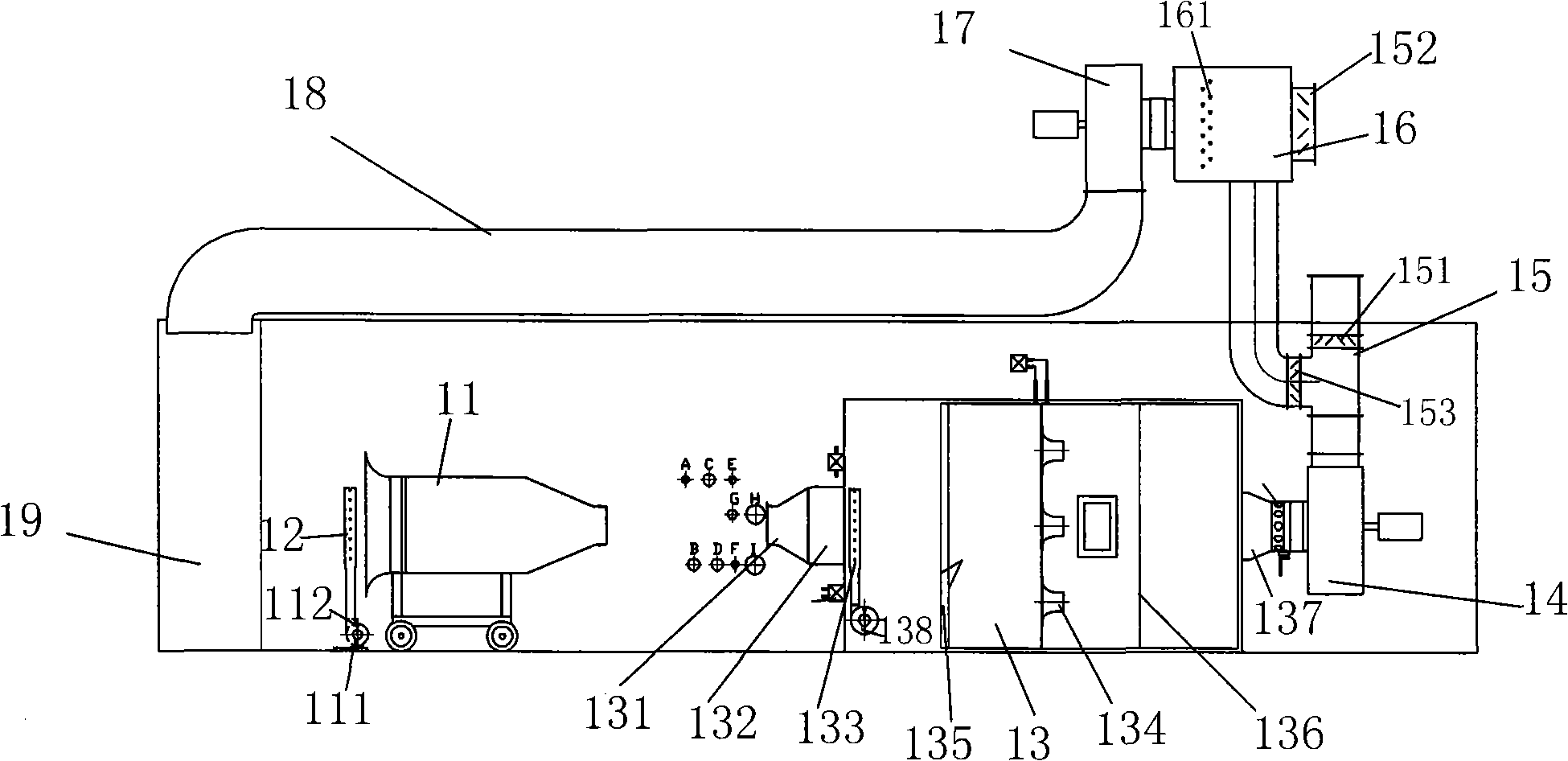

[0036] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0037] The purpose of the heat exchanger performance test of the present invention is to simulate the working conditions of the test piece of the heat exchanger under test, and to detect whether its heat transfer capacity and resistance meet the design requirements; the other is to obtain different types of heat exchangers by testing standard test pieces. Establish and enrich the performance database of fins based on the performance curve data of specification fins. In order to have a better, higher and more economical design level. The specific plan is as follows.

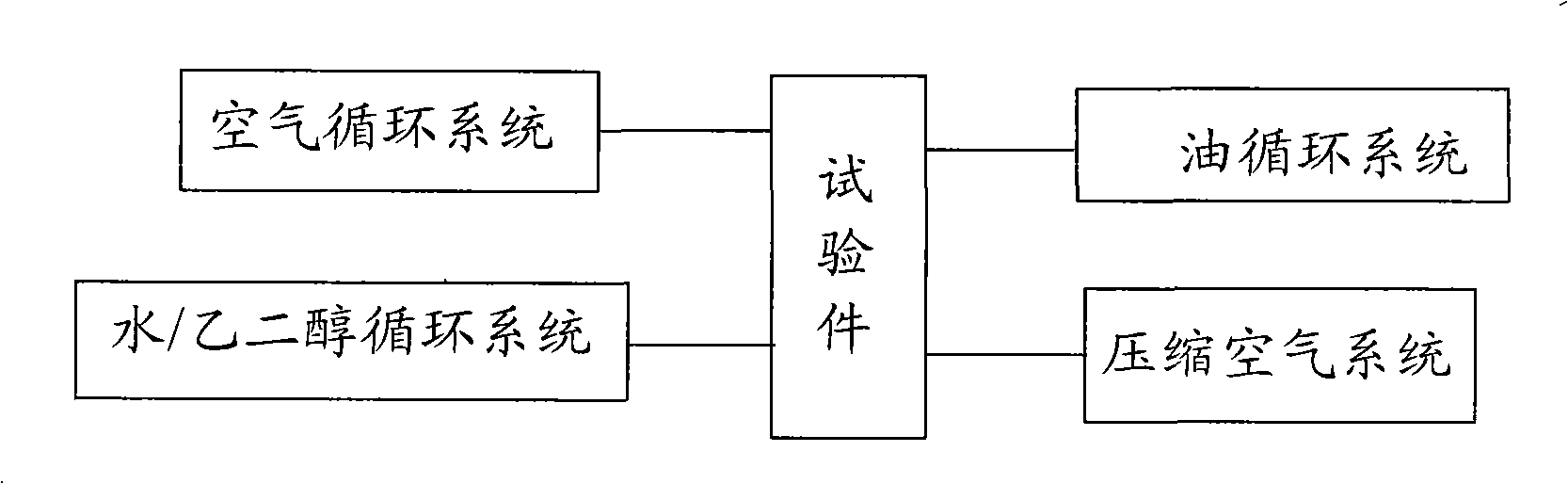

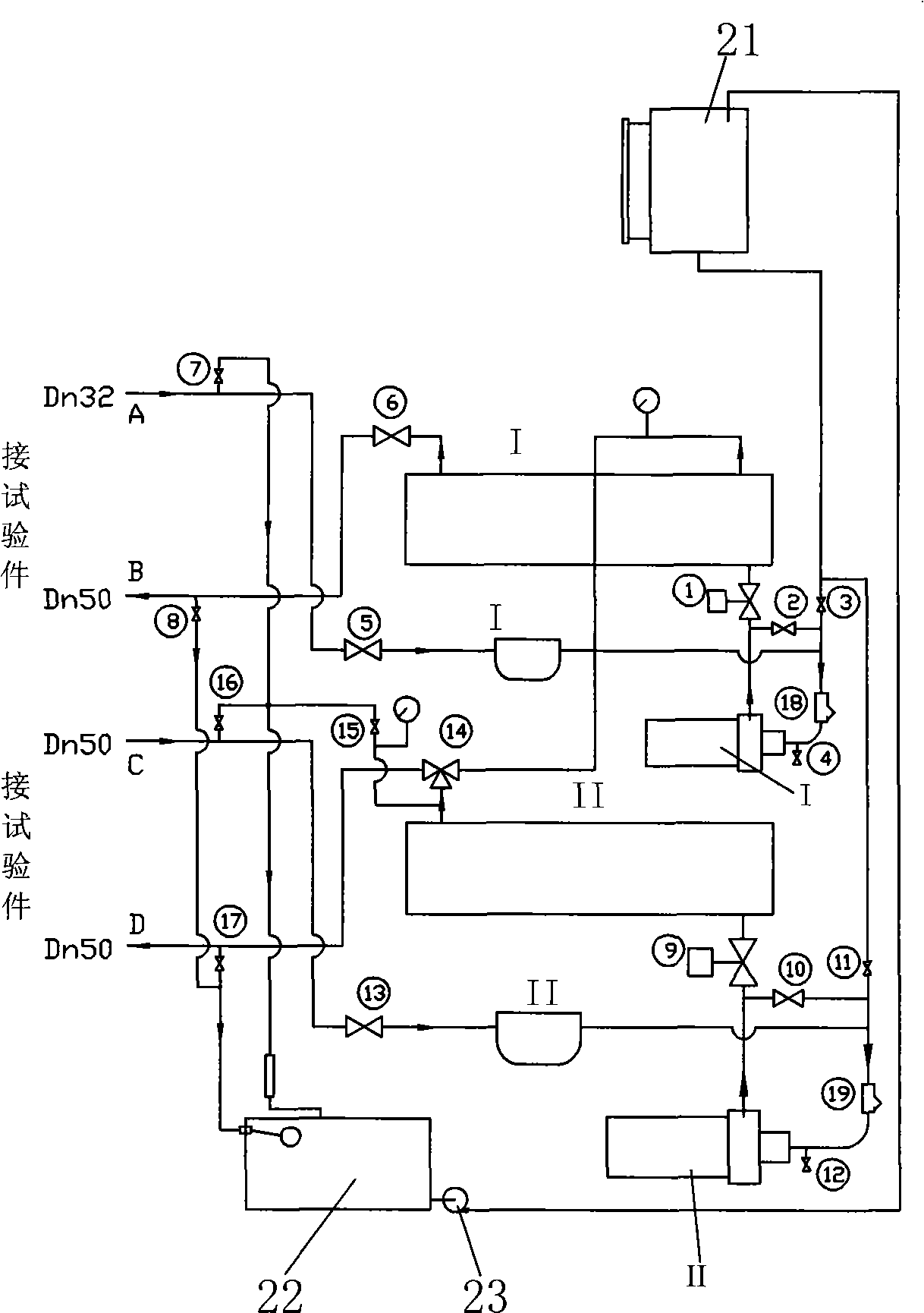

[0038] Reference figure 1 , Which includes the air circulation system with air as the fluid medium for testing the performance of the heat exchanger test pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com