Rolling compounding method for aluminum/magnesium/titanium three-layer composite plate

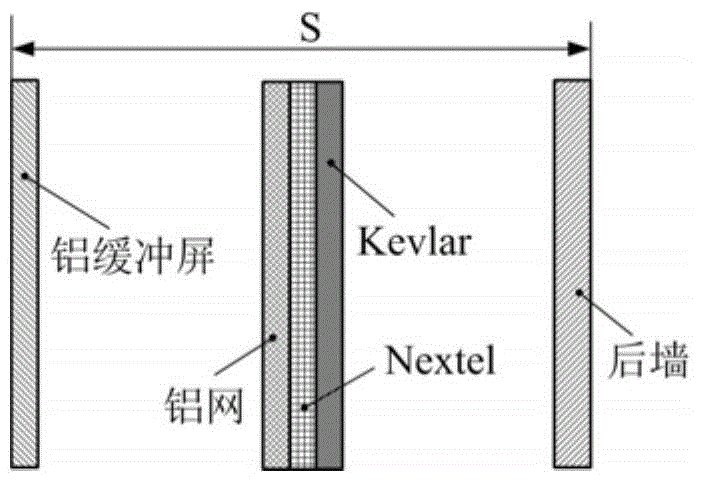

A technology for rolling clad and clad plates, which is used in metal rolling, metal rolling, manufacturing tools, etc., and can solve the problems of poor resistance to high-speed impact damage of protective materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

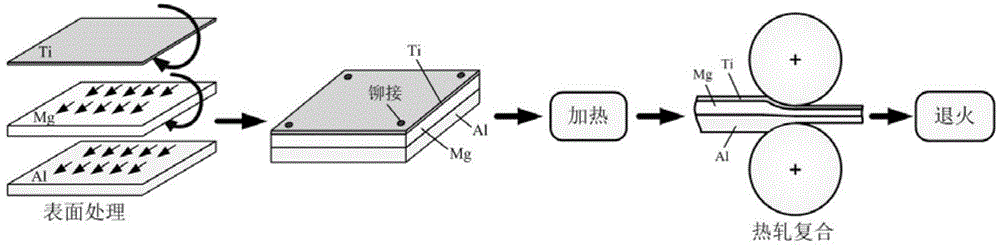

[0030] Select aluminum alloy (AA6061), magnesium alloy (AZ31) and titanium alloy plates (TC4) with a thickness of 1mm, 2.2mm and 0.5mm, and the size specification is 500mm×350mm. Annealing pretreatments were performed before rolling (Al alloy AA6061, annealed at 450°C for 1h; magnesium alloy AZ31, annealed at 350°C for 0.5h; titanium alloy TC4 at 500°C for 1h).

[0031] Use a stainless steel brush to polish the surface of the annealed plate, then rinse it with clean water and dry it.

[0032] The surface-treated slabs are stacked in the order of aluminum, magnesium, and titanium, and the ends are riveted and fixed.

[0033] The thickness of the composite billet is about 3.6mm, put it into a heating furnace and heat it for 10 minutes at a heating temperature of 350°C, then take it out for hot rolling and compounding, and the reduction is about 30%.

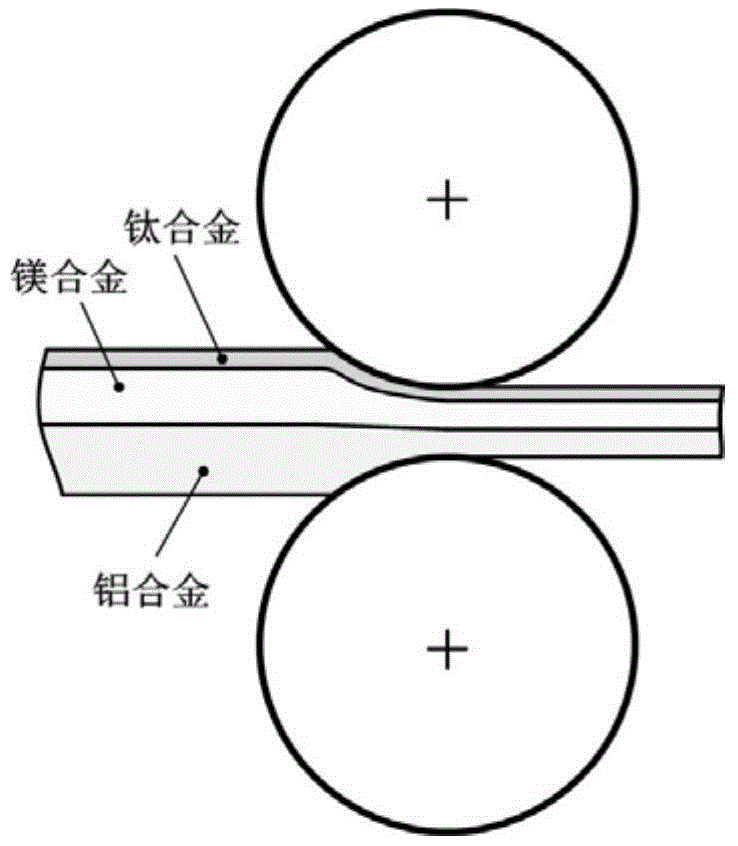

[0034] Rolling deformation zone and aluminum / magnesium / titanium three-layer composite plate structure such as image 3 shown. ...

Embodiment 2

[0038] Select aluminum alloy (AA5052), magnesium alloy (AZ61) and titanium alloy plate (TA2) with a thickness of 1.3mm, 1mm and 0.25mm, and the size specification is 400mm×300mm. Annealing pretreatment was carried out before rolling (aluminum alloy AA5052, annealed at 450°C for 1h; magnesium alloy AZ61, annealed at 350°C for 0.5h).

[0039] Use a stainless steel brush to polish the surface of the annealed plate, then rinse it with clean water and dry it.

[0040] The surface-treated slabs are stacked in the order of aluminum, magnesium, and titanium, and the ends are riveted and fixed.

[0041] The thickness of the composite billet is about 2.5mm, put it into a heating furnace and heat it for 10 minutes at a heating temperature of 400°C, then take it out for hot rolling and compounding, and the reduction is about 40%.

[0042] Rolling deformation zone and aluminum / magnesium / titanium three-layer composite plate structure such as image 3 shown. Annealing treatment is carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com