Design method for end part- and root-reinforced few-leaf variable-section steel plate springs

A leaf spring, variable section technology, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve the problem that can not meet the design requirements of the end and root reinforced type small-piece variable section leaf springs, and it is difficult to obtain accurate and reliable parameters. Design value, inability to meet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

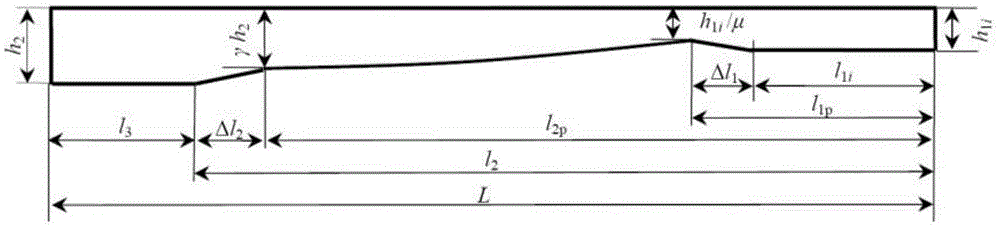

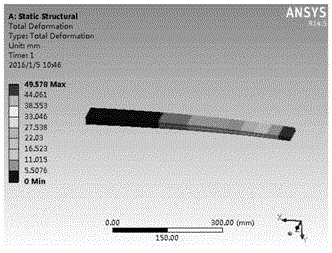

[0051] Embodiment 1: A schematic diagram of a half-symmetrical structure of a single-leaf spring of a certain end and end-reinforced few-piece variable-section leaf spring is as follows figure 2 As shown, among them, half length L of each leaf spring = 575mm, width b = 60mm, half of the installation distance l 3 =55mm, the thickness ratio of the oblique section at the root γ=0.90, the thickness ratio of the oblique section at the end μ=1.17, the length of the oblique section at the root Δl 2 =30mm, the length of oblique line at the end Δl 1 =30mm; elastic modulus E=200GPa, safe allowable stress [σ]=500MPa. Half of the rigidity design requirement value K M =24N / mm, design the structural parameters of the end and root reinforced few-piece variable-section leaf spring, and conduct ANSYS on the deformation and half of the stiffness of the leaf spring under the condition of half the maximum load, that is, the single-end load P=1200N verify.

[0052] The design method of the en...

Embodiment 2

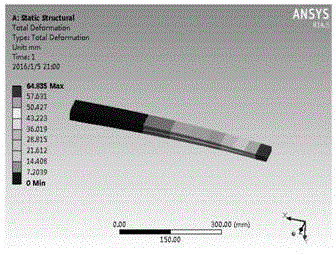

[0084] Embodiment 2: The structure diagram of half of the single-leaf spring of a certain end and root reinforced few-piece variable-section leaf spring is as follows figure 2 As shown, among them, the half length of each leaf spring L=600mm, width b=60mm, modulus of elasticity E=200GPa, half of the installation distance l 3 =60mm, the thickness ratio of the oblique section at the root γ=0.90, the thickness ratio of the oblique section at the end μ=1.17, the length of the oblique section at the root Δl 2 = 30mm, length Δl of oblique section at the end 1 = 30mm, safe allowable stress [σ] = 500MPa. Half of the rigidity design requirement value K M =46N / mm, design the structural parameters of the end and root reinforced few-piece variable-section leaf spring, and analyze the deformation and half The stiffness is verified by ANSYS simulation.

[0085] Using the same design method and steps as in Embodiment 1, the structural parameters of the end and root reinforced few-piece ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com