Prefabricated steel concrete combined ring main unit foundation

A combined ring and prefabricated technology, applied in infrastructure engineering, construction, etc., can solve problems such as waste of resources, poor foundation stability and durability, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

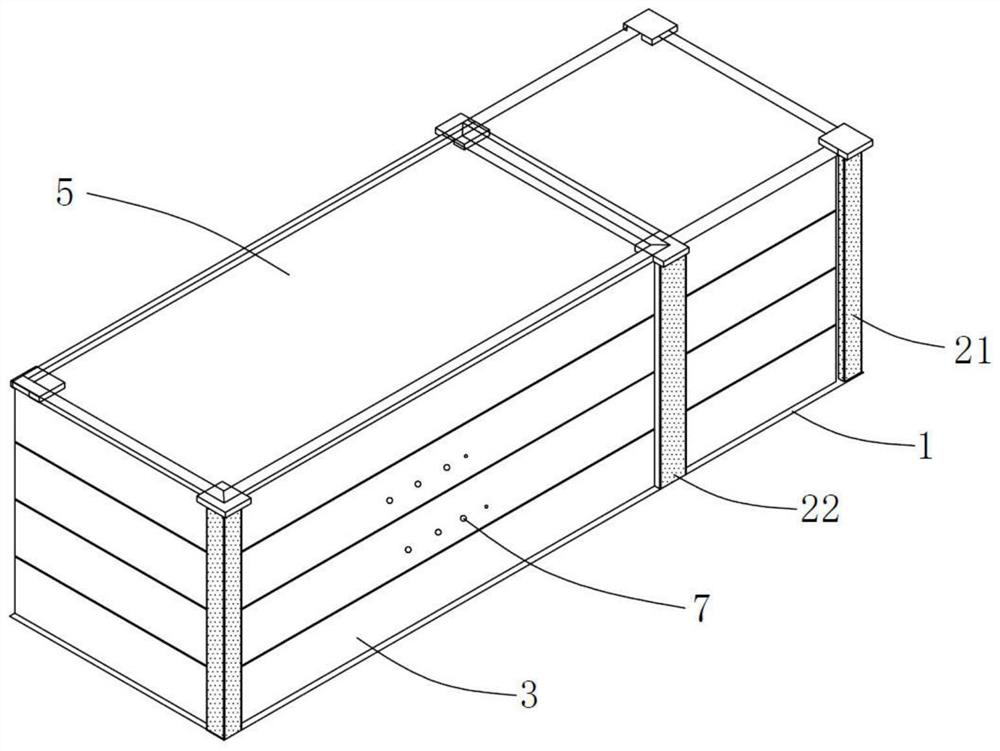

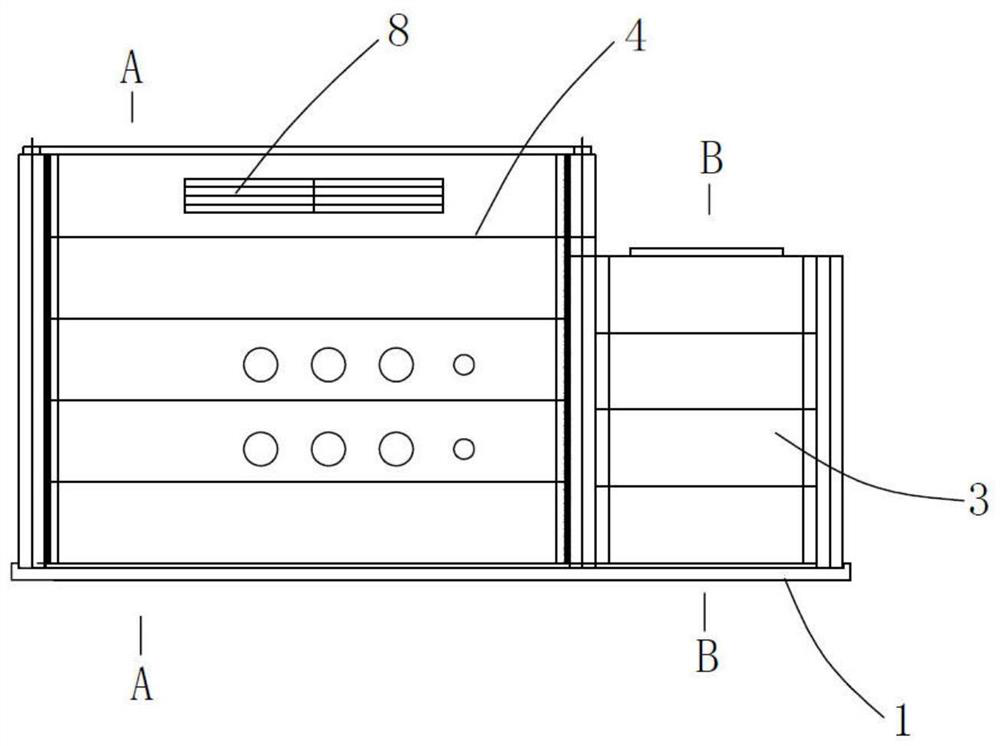

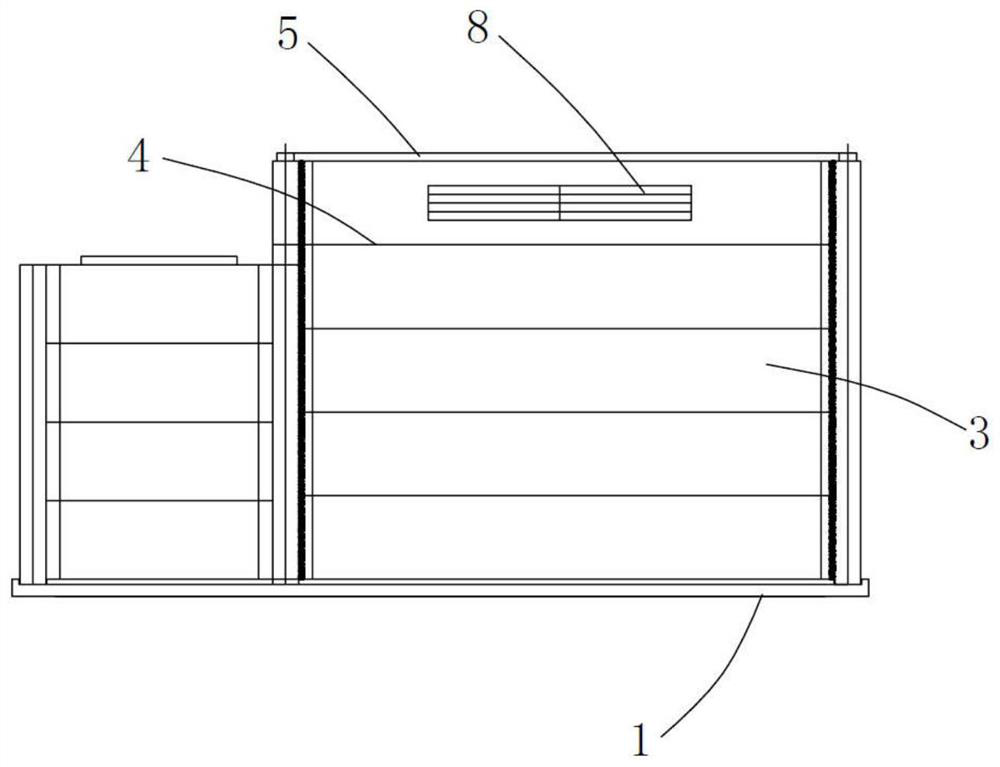

[0025] Embodiment: Referring to the accompanying drawings, the foundation of the prefabricated steel-concrete combined ring network cabinet in this embodiment includes a prefabricated bottom plate 1 and detachable uprights arranged on the four sides of the bottom plate 1, wherein the uprights include four corners of the bottom plate The corner column 21 at the position and the standard column 22 at the edge of the bottom plate are detachably connected with impermeable concrete prefabricated wall panels 3 to form the four walls of the ring network cabinet. The wall panels 3 It is a multi-level superposition structure from bottom to top; a ring beam 4 is arranged on the top of the wall panel, and a cover plate 5 is arranged on the ring beam 4 .

[0026] The specific splicing form is that the anti-seepage concrete prefabricated floor is surrounded by assembly connection grooves and pre-embedded butt bolts, the bottom wall plate is reserved for bottom plate butt bolt holes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com