Prefabricated assembled integrated foundation pit horizontal supporting system and construction method thereof

A technology of horizontal support and prefabricated assembly, which is applied in basic structure engineering, excavation, construction, etc. It can solve problems such as uncontrollable construction quality of on-site assembly, unstable horizontal support system structure, and ineffective connection of ring beam corners, etc., to achieve hoisting and The effect of construction quality assurance, fast construction and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

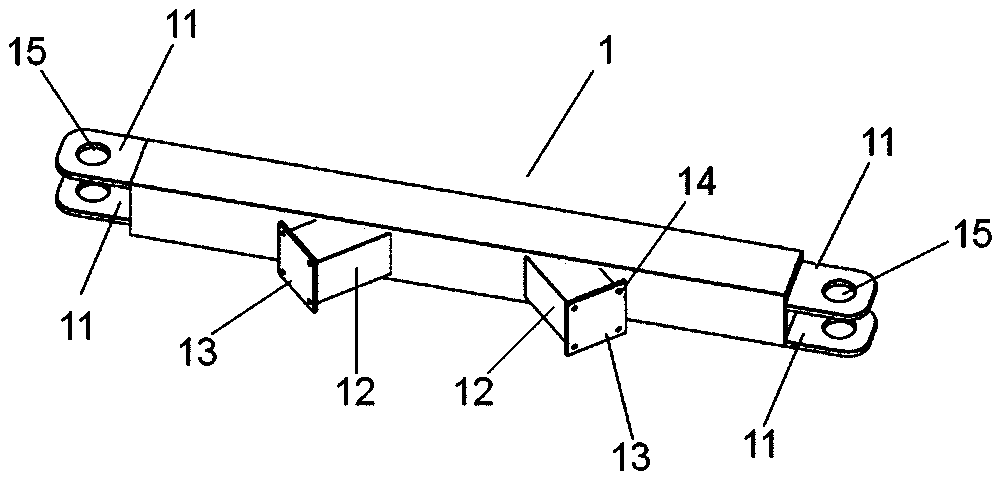

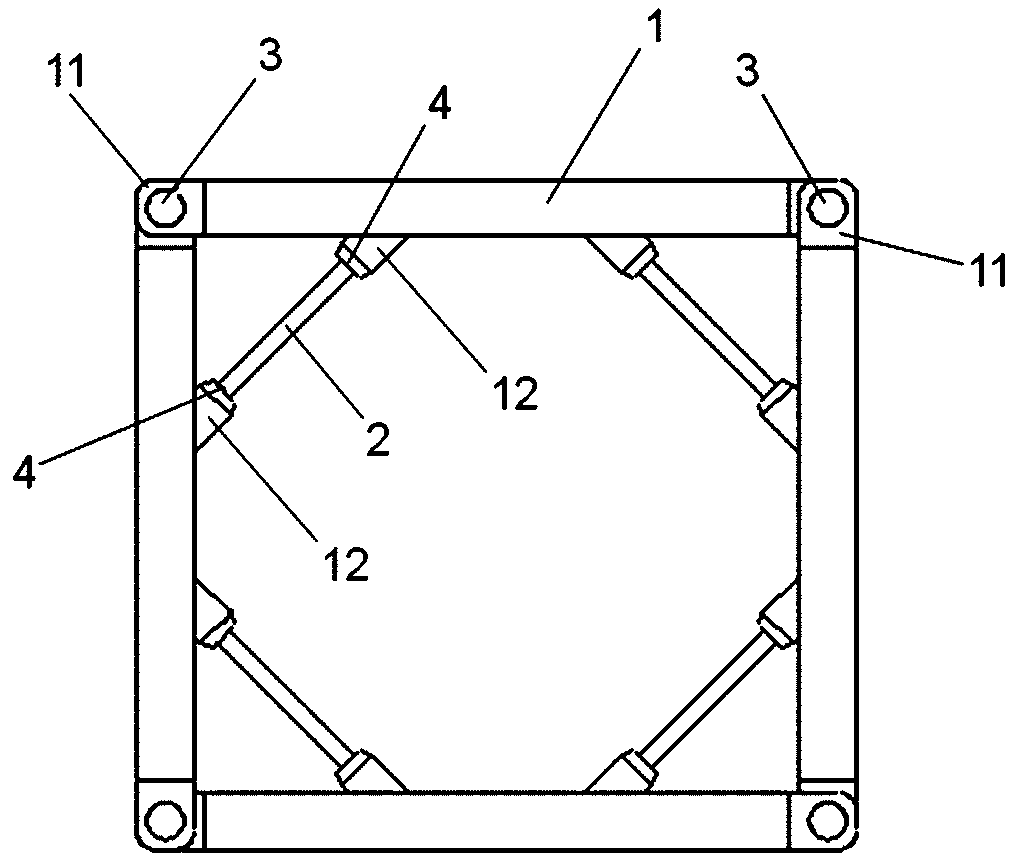

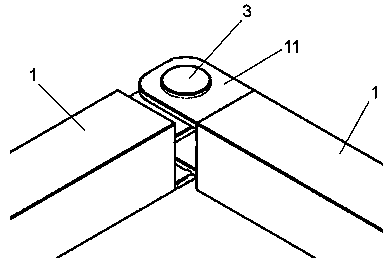

[0030] see Figure 1 to Figure 4 , a prefabricated and assembled monolithic foundation pit horizontal support system, including a number of ring beam members 1 connected end to end to form a whole; The pieces 11 need to be stacked up and down and then fixed, so that the hinged pieces 11 of the adjacent ring beam members 1 can be inserted into each other; the middle section of the ring beam member 1 is respectively welded with two corbels 12 with different orientations and arranged obliquely; The planar end of the leg 12 facing away from the ring beam member 1 is welded with a corbel connection plate 13; two corbels 12 close to each other on the adjacent ring beam member 1 are connected by braces 2 to fix the adjacent ring beam member 1 .

[0031] Further, the four ring beam members 1 are connected end to end to form a rectangular integral ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com