Movable type laser cladding complete equipment integrated cabin system

A technology of laser cladding and complete equipment, which is applied in the direction of metal material coating process, coating, etc., can solve the problems of inability to meet the diverse needs of the site, low production efficiency, single-machine handling, etc., to achieve convenient hoisting and transportation, and production efficiency High, high cladding power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

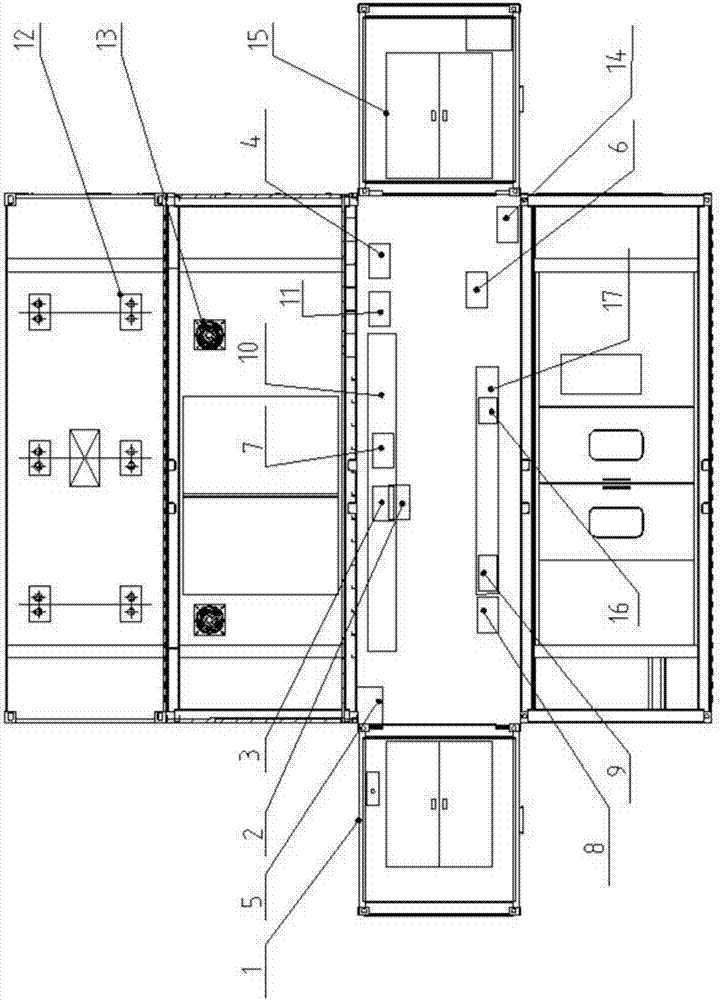

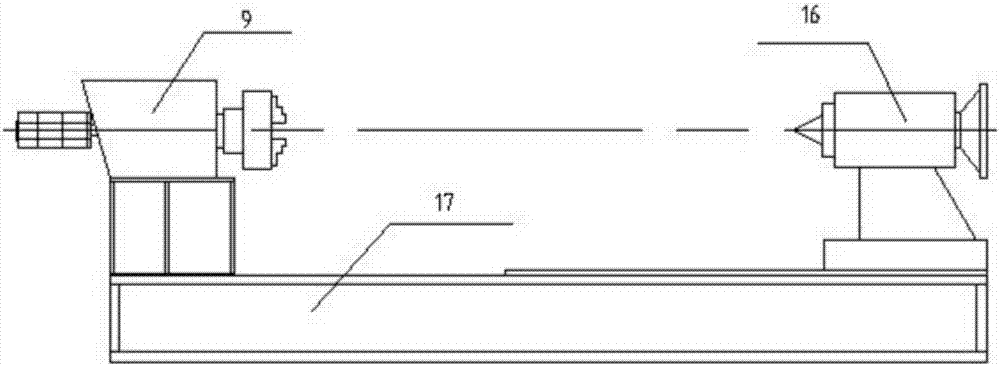

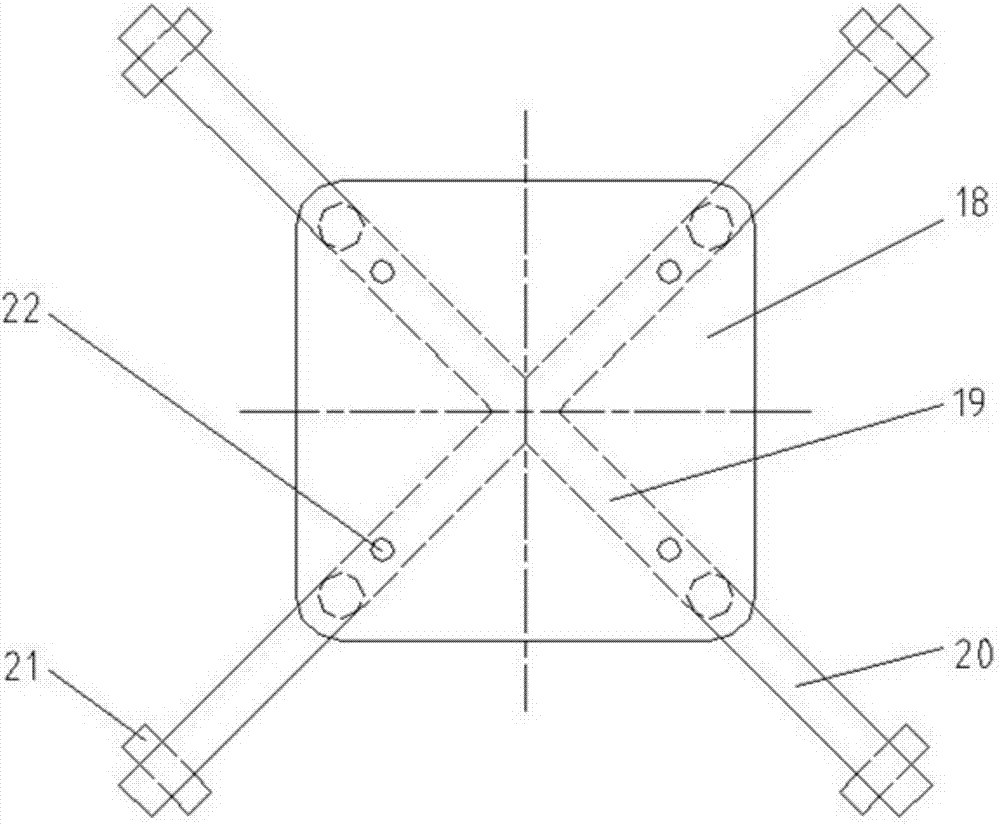

[0020] Such as Figure 1-Figure 3 As shown, the mobile laser cladding complete set of equipment integrates the shelter system, including the shelter shell 1, the laser 2, the robot 3, the voltage stabilizer 4, the chiller 5, the air compressor 6, the powder feeding system 7, and the dryer 8. Positioner 9, robot slide 10, off-machine operating platform 11, lighting system 12, temperature adjustment system 13, main power control cabinet 14, tailstock top 16 and tailstock slide 17; shelter shell 1 is A rectangular parallelepiped structure composed of carbon steel square tubes and stainless steel plates. The bottom of the shelter shell 1 is provided with reinforcing ribs. The design strength is such that the overall deformation does not occur during lifting. , water chiller 5, air compressor 6, dryer 8, robot slide 10, off-machine operating platform 11, main power control cabinet 14, tailstock slide 17, chiller 5, and off-machine operating platform 11 are respectively located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com