Composite column with ultra-short studs and double-layer high-strength spiral stirrups and construction method

A technology of spiral stirrups and superimposed columns, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as structural performance weakening, collapse, and degradation of material mechanical properties, reduce construction materials and construction hours, reduce component weight, The effect of difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

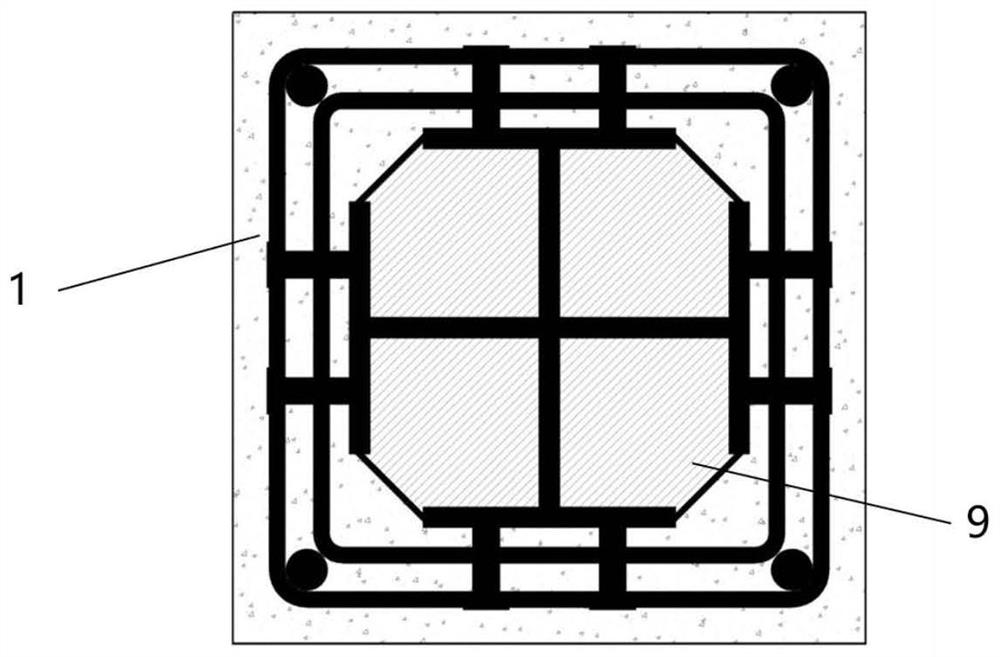

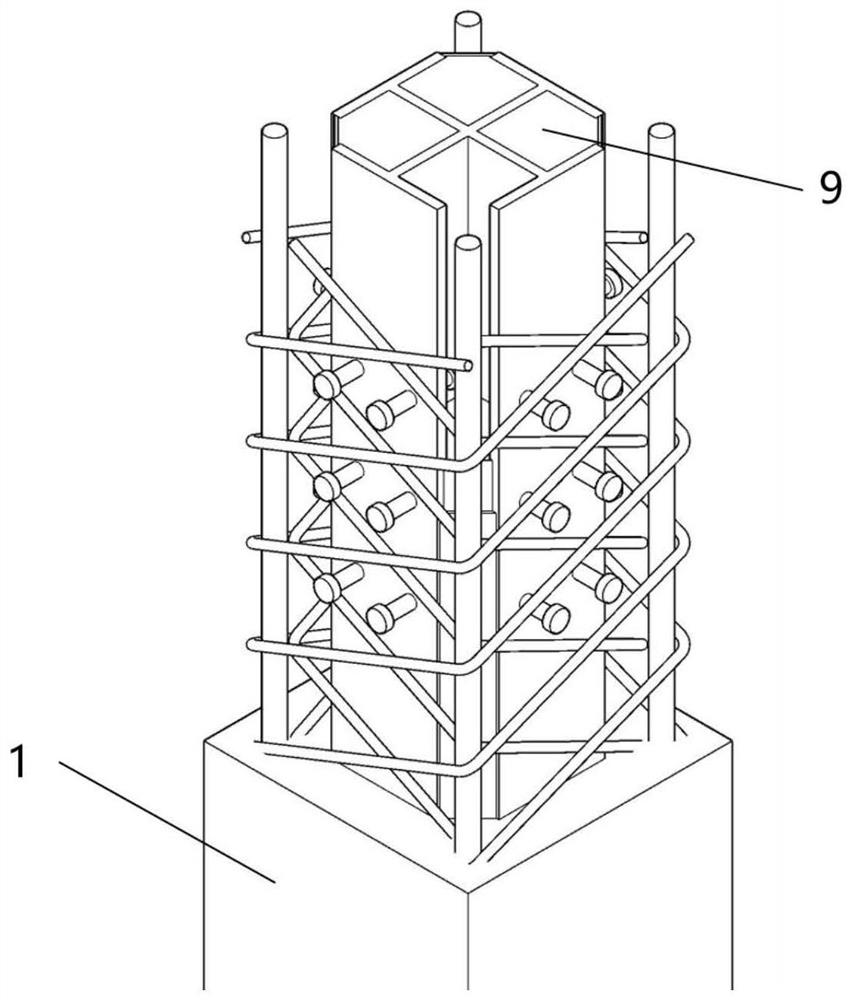

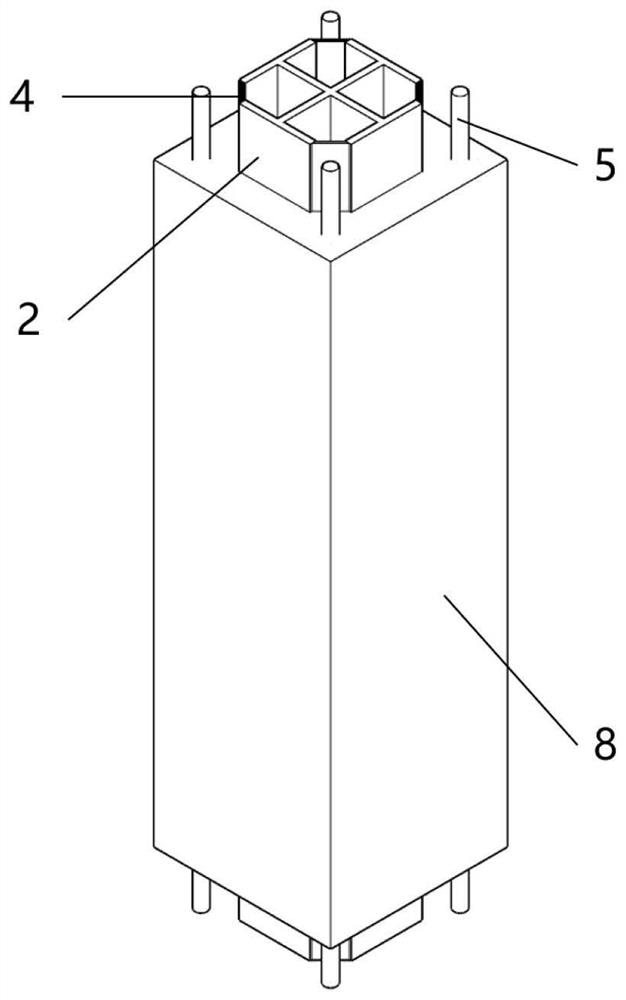

[0053] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0054] According to an ultra-high-performance concrete laminated column with ultra-short embossed and double-layer high-strength spiral ribs, a partial prefabricated part of the cast, has excellent seismic and refractive performance, and the prefabricated transport is light, construction quality Ok, design flexibly, differentiated use of concrete, low cost, etc. Among them, the double-layer high-strength spiral ribs can make the high-temperature burst of ultra-high performance concrete have been significantly inhibited. The deterioration of the mechanical properties of the components will slowly slow down, which can greatly improve the refractive properties of the superior performance concrete laminated column.

[0055] Specific figure 1 and figure 2 As shown, the present invention is mainly composed of a prefabricated ultra-high performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com