Miniature light-emitting diode display panel and manufacturing method thereof

A technology of light-emitting diodes and display panels, applied to static indicators, instruments, electrical components, etc., can solve the problems of metal wire printing and alignment in mobile printing, and achieve high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

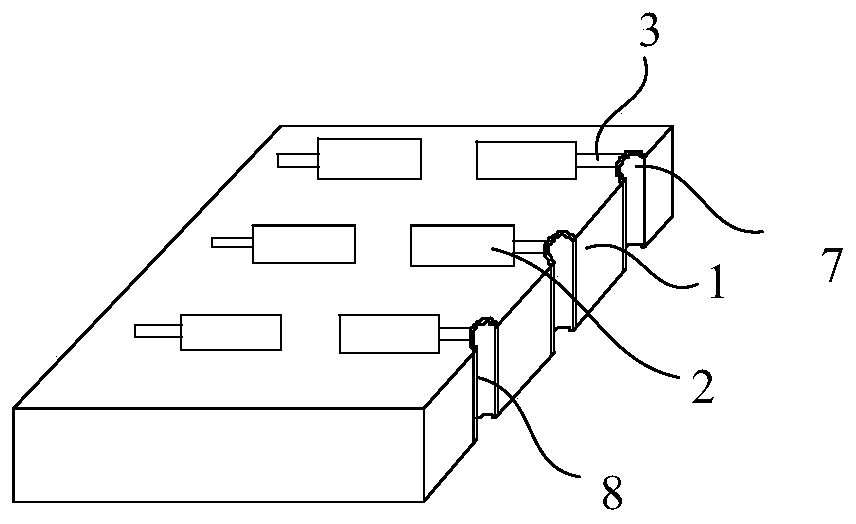

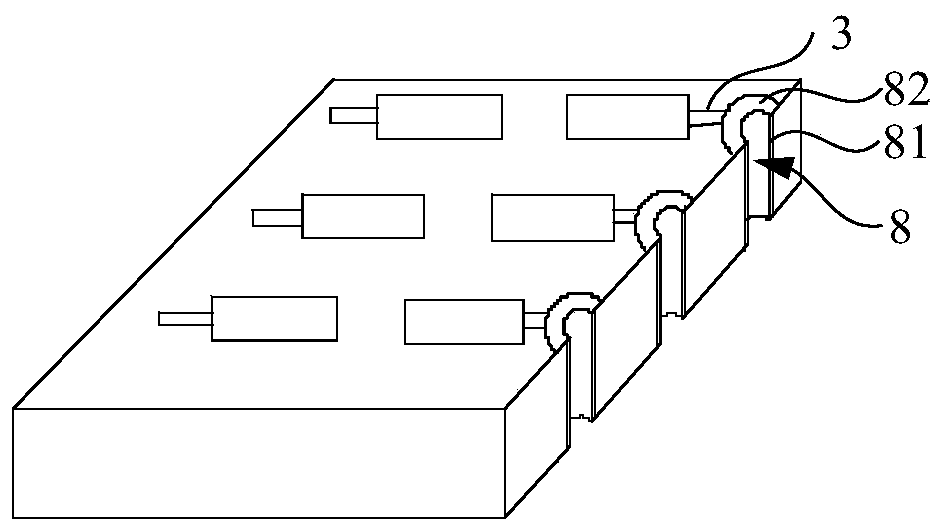

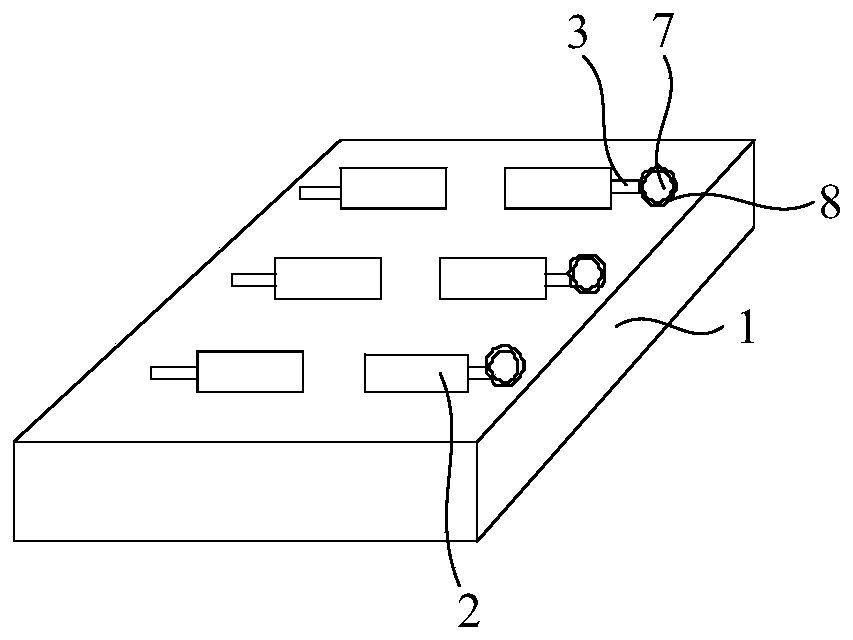

[0071] In a specific implementation manner, the specific steps of forming openings corresponding to the signal lines one-to-one and metal film connection parts in the preset edge area may be as follows: Figure 7 , Figure 8a-8d Shown:

[0072] S701: Form a plurality of through holes corresponding to the signal lines in the preset edge area, and the centers of the plurality of through holes are on the same cutting line; specifically, as Figure 8a As shown, in the structure formed in this step, there are through holes 5 corresponding to the signal lines 3 in the predetermined edge region of the base substrate 1;

[0073] S702: Plating a metal film on at least the sidewall of the through hole; if Figure 8b As shown, there is a metal film 6 on the side wall of the through hole 5;

[0074] S703: Cut the base substrate along the cutting line to form the opening in the shape of a half hole and the connection part of the metal film; as Figure 8c As shown, the substrate is cut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com