Manufacturing method of concrete relief wall

A production method and technology for concrete walls, which are applied to the preparation of building components on site, the treatment of walls and formwork, etc., which can solve the problems of easily affecting the integrity of relief patterns, poor overall molding effect of reliefs, and easy damage to relief patterns, etc. , to achieve the effect of convenient repair of local defects, good molding effect and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

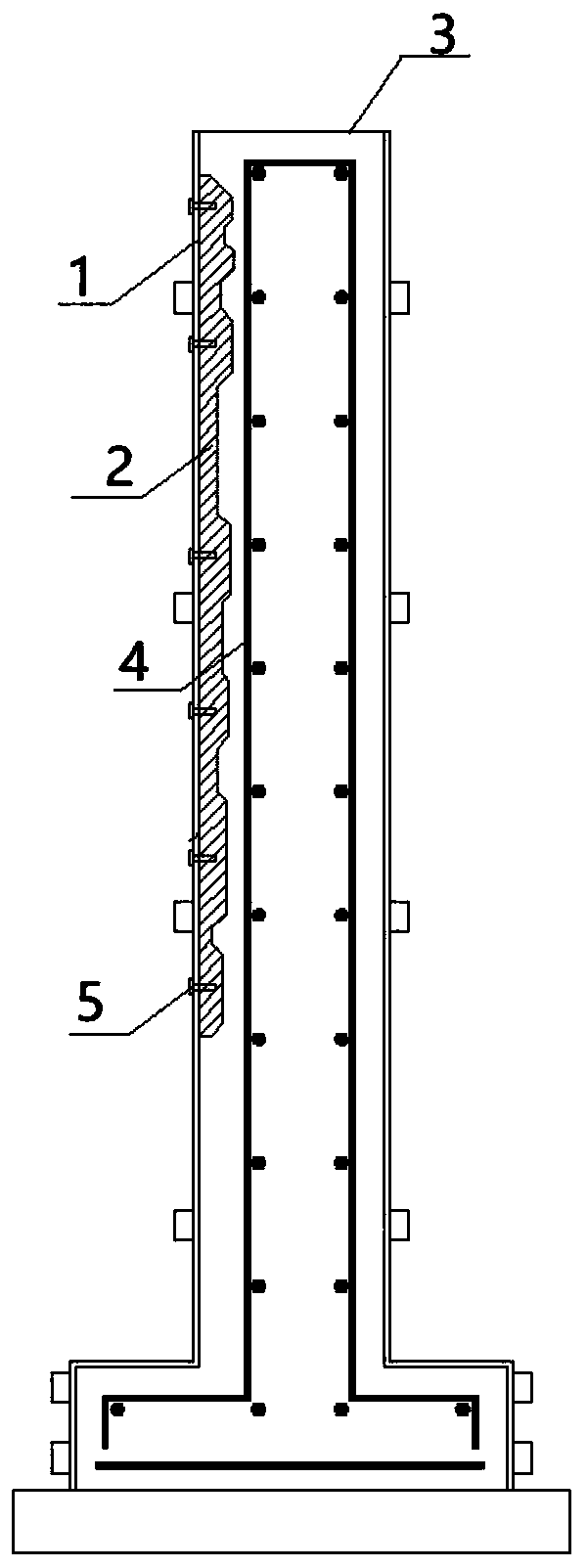

[0036] The present embodiment provides a kind of manufacture method of concrete relief wall, adopts such as figure 1 The pouring mold 3 for the concrete relief wall shown is to produce a concrete relief wall with relief patterns recessed into the wall. Include the following steps:

[0037] Step 1. According to the design plan, use the engraving machine tool or 3D printing to process the waxy female mold 2. When the waxy female mold 2 is large, it can be processed in sections to form segmented components. The material is paraffin wax, and attention should be paid to cooling down when engraving Ventilate to prevent softening of the material. The processed components are bonded with hot-melt wax, and local defects and burrs can be manually polished or repaired.

[0038] Step 2: To make the embossed formwork, first select the outer formwork 1, and the outer formwork 1 is a straight plate made of steel or aluminum, with a thinner thickness, which is convenient for demoulding in t...

Embodiment 2

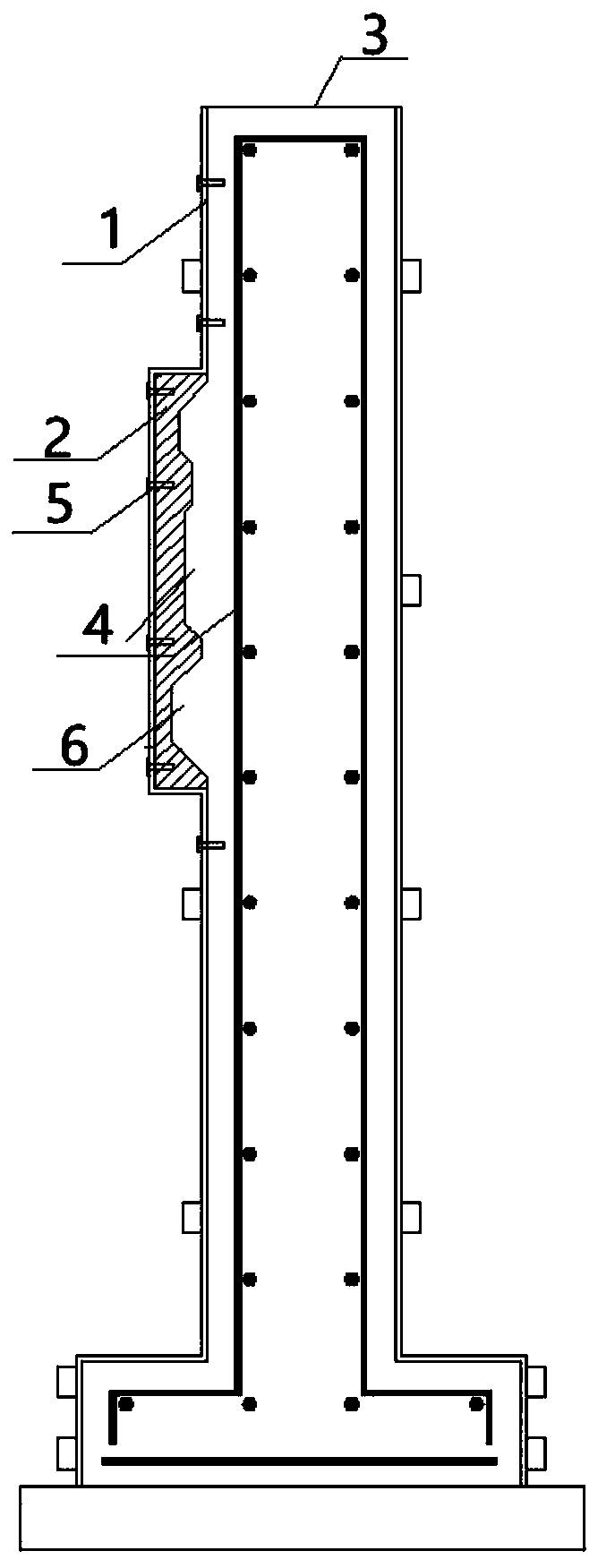

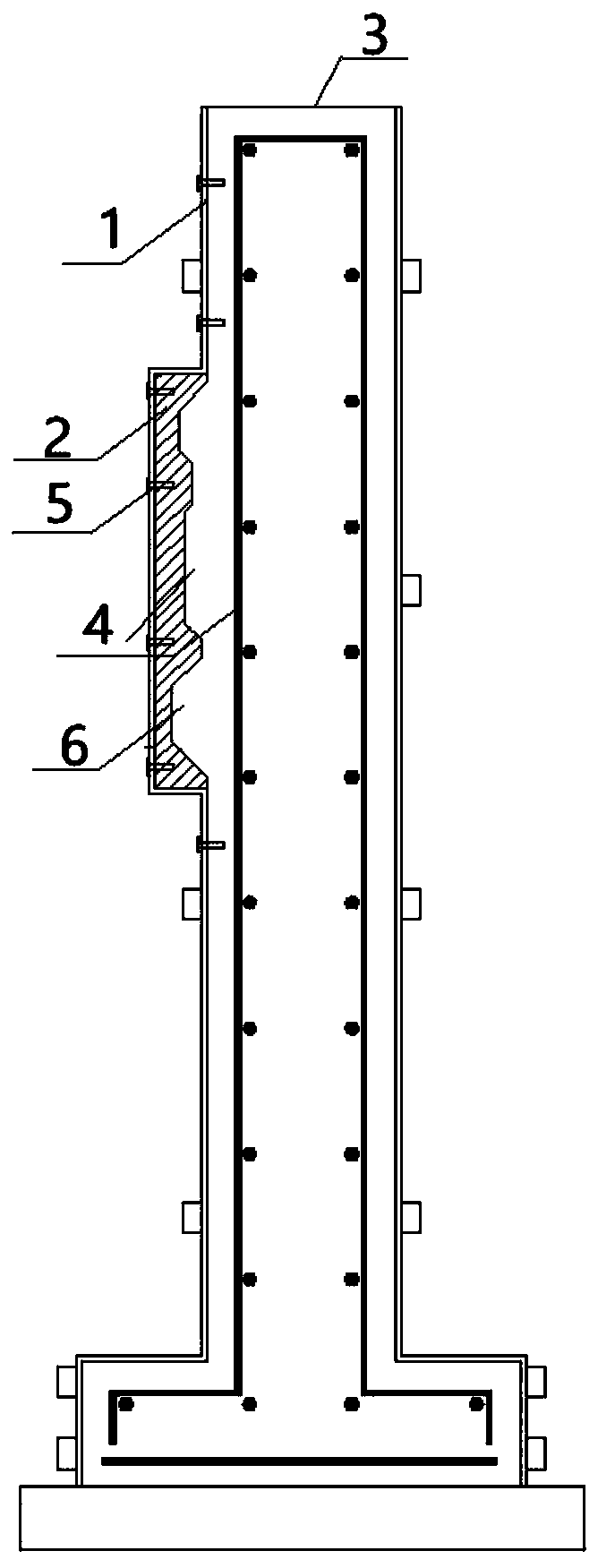

[0047] The present embodiment provides a kind of manufacture method of concrete relief wall, adopts such as figure 2The pouring mold 3 for the concrete relief wall shown in the figure produces a concrete relief wall with relief patterns protruding from the outside of the wall.

[0048] The manufacturing method of this embodiment is roughly the same as that of Embodiment 1, the difference is that in step 2, when making the embossed template, the outer template 1 protrudes outward at the embossed position to form a wax mold installation cavity 6, and the other parts are straight plates, wax molds The depth of the installation cavity 6 is equal to the depth of the waxy female mold 2, and the waxy female mold 2 is integrally filled in the wax mold installation cavity 6 to form a relief pattern protruding outside the wall after demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com