Construction method for prefabricated decorative finish of steel structure stair steps

A construction method and steel structure technology, applied to stairs, stepped structures, pedals, etc., to achieve the effect of no need for secondary decoration, flexible combination, and light overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

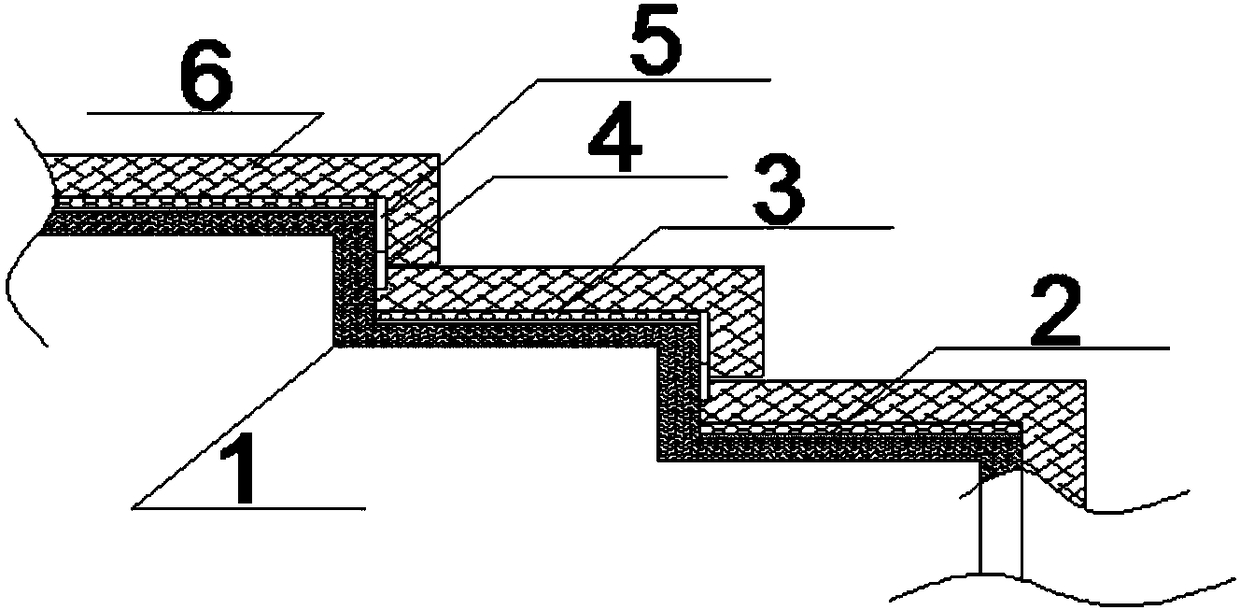

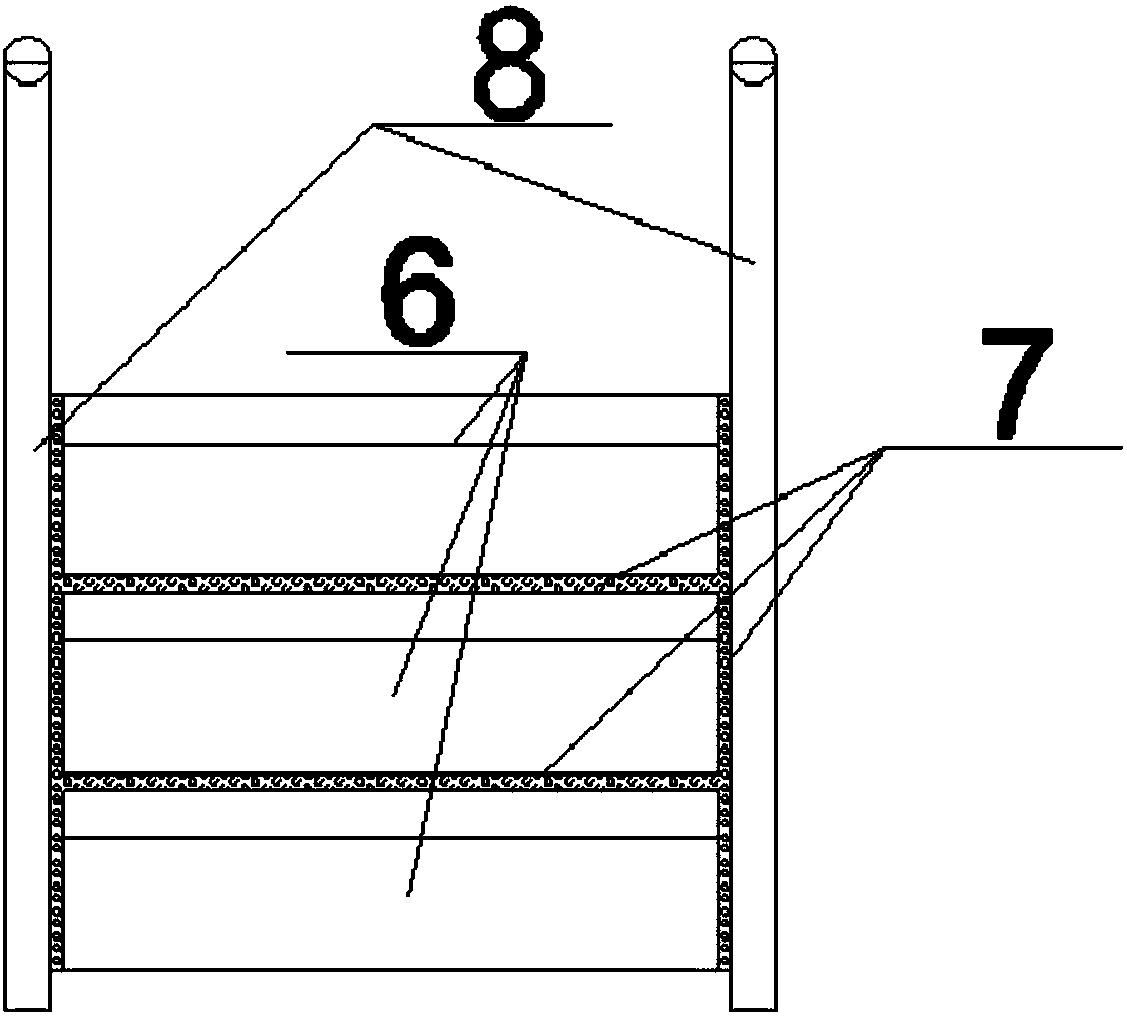

[0025] A construction method of prefabricated finishing (GRC) material for steel structure stair steps

[0026] 1. If figure 1 Shown:

[0027] 1.1 Cleaning of the base: remove the dirt, mortar blocks, garbage and other attachments on the base of the stair steps. If there are some prominent places, they should be chiseled. Check whether the quality of the grassroots meets the requirements;

[0028] 1.2 The horizontal line, vertical line and GRC product position line popped up on the base layer must be horizontal and vertical, and the gap between parts is uniform and consistent, and it is about ≤5mm;

[0029] 1.3 On the surface of the base layer, evenly apply a layer of 2mm thick acrylic adhesive layer;

[0030] 1.4 Cover with a 5mm thick rubber plate protective layer, and level it with a level;

[0031] 1.5 Pop up the horizontal line, vertical line and GRC product position line according to the base layer, install the GRC cover plate, and adjust the gap of the GRC cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com