Composite board for building, processing method of composite board and mobile house adopting composite board

A technology of composite panels for construction, which is applied in the direction of buildings, building components, building elements, etc., can solve the problems of poor wear resistance, poor waterproofness, and easy corrosion, and achieve a wide range of uses, long-lasting thermal insulation performance, and simple manufacturing methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

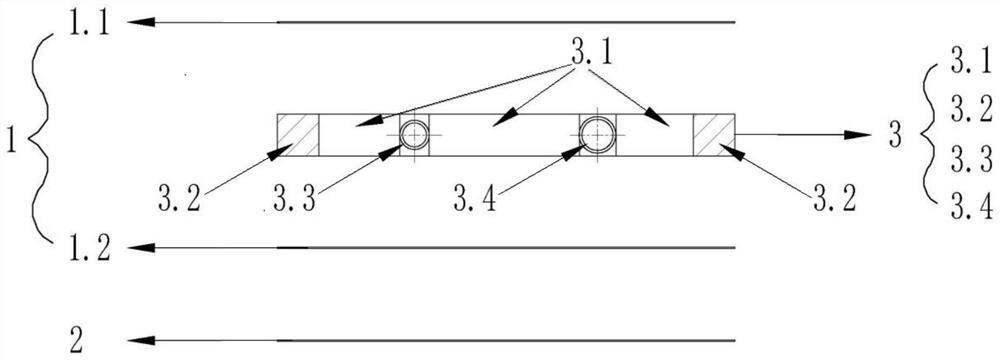

[0029] This embodiment provides a composite panel for building, such as figure 1 As shown, a base material layer 2 is included, an insulation layer 3 is provided above the base material layer 2 , and carbon fiber layers 1 are provided on both sides of the insulation layer 3 .

[0030] Among them, the base material layer 2 adopts glass steel plate, which has good insulation, high tensile strength, small elongation and high mechanical strength; high elastic coefficient and good rigidity; large elongation within the elastic limit and high tensile strength, so the absorption High impact energy; inorganic fiber, not easy to burn, good insulation, good chemical resistance, low water absorption, strong heat resistance.

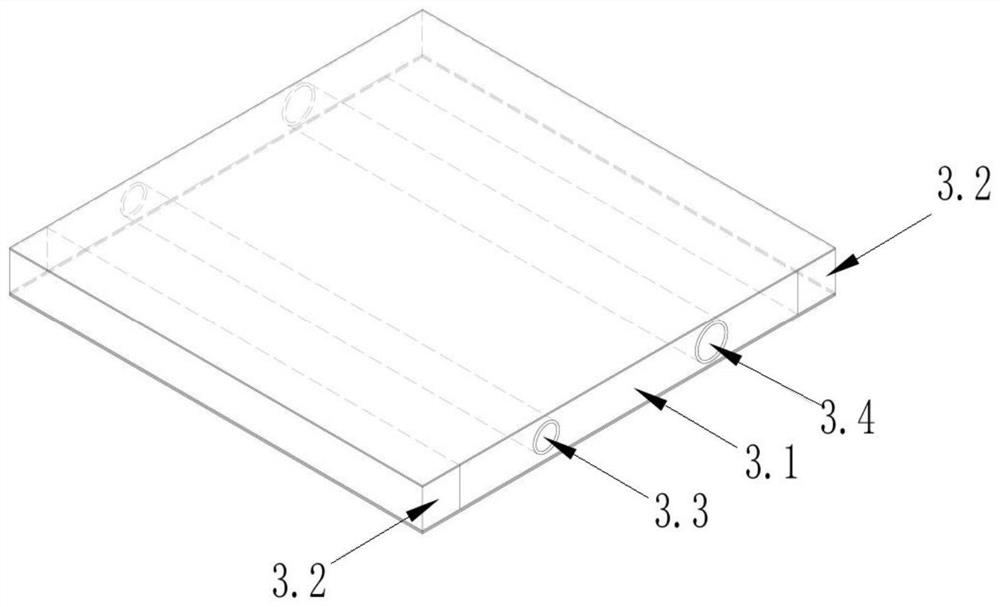

[0031] Further, as figure 2 shown. Insulation layer 3 includes XPS extruded board 3.1, which is distributed with reinforcing ribs 3.2, wire pipes 3.3 and water pipes 3.4; XPS extruded board 3.1 has the characteristics of high thermal resistance, low linearity, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com