Aluminum alloy cross beam and upright post connecting structure for fixing glass curtain wall

An aluminum alloy beam and connecting structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of increasing materials and joints, small operating space, waste materials, etc., to enhance the performance of profiles, improve installation efficiency, less seam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

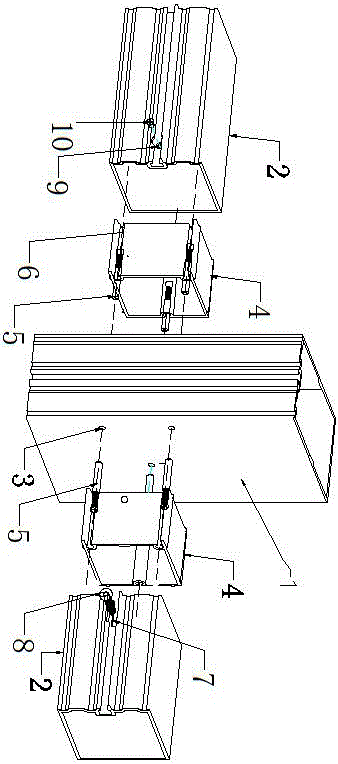

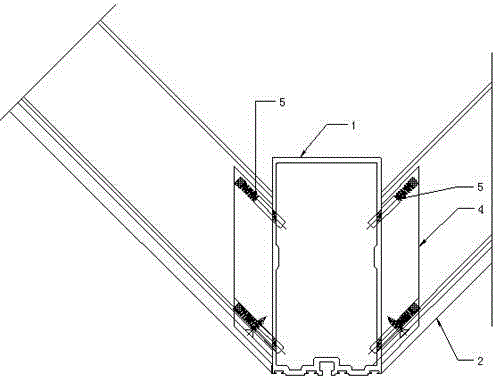

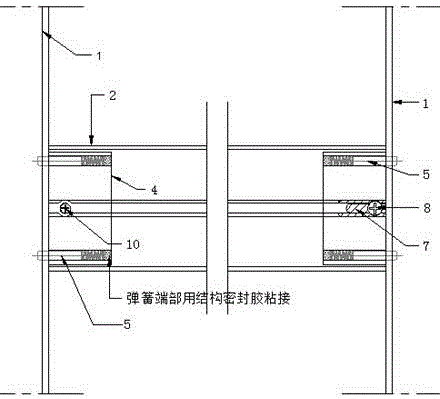

[0019] Embodiment 1, the connection structure between the aluminum alloy beam and the column for fixing the glass curtain wall proposed by the present invention, such as figure 1 with 3 As shown, it involves the connection of the beam 2 between two aluminum alloy columns 1. The specific structure is to pre-open the installation hole 3 at the position where the beam 2 is installed on the aluminum alloy column 1, and the installation holes 3 are arranged in a zigzag shape. Ferrules 4 are socketed and fixed at both ends of the beam 2 , and three steel pin fixing holes 6 arranged in a triangle are arranged on the ferrule 4 . A spring steel pin 5 is installed on the steel pin fixing hole 6 of the ferrule, and the spring end of the spring steel pin 5 is bonded with structural sealant. The position of the spring steel pin 5 corresponds to the mounting hole on the beam 2. , when the end of the spring steel pin 5 encounters the mounting hole 3, it will automatically pop up and be inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com