OLED (organic light-emitting diode) display unit and OLED spliced display screen with same

A display unit and substrate technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of unable to display images in the frame area, unable to achieve seamless splicing, discontinuous screen images, etc., to achieve optimization Stitching effect, small patchwork, effect of increasing brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

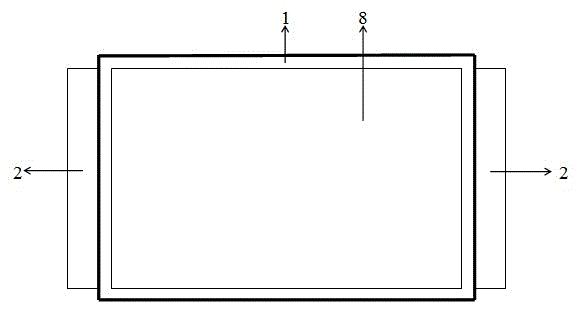

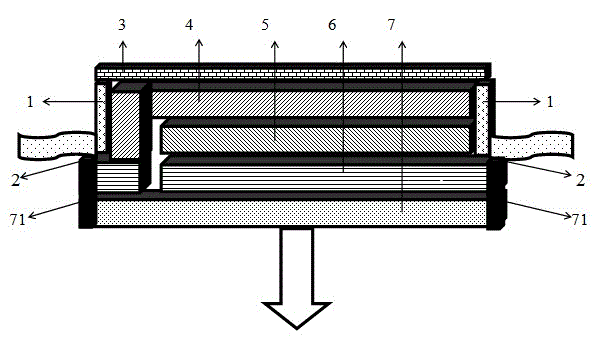

[0036] like Figure 5 As shown, it is a schematic structural diagram of an OLED display unit in this embodiment; an OLED display unit includes a substrate 7, an OLED module, and an encapsulation layer, and the OLED module is composed of an anode layer 6, an organic layer 5 and a cathode layer 4 stacked on top of each other. , the encapsulation layer is arranged on the periphery and the front surface of the OLED module.

[0037] Wherein the anode layer 6, the organic layer 5, and the cathode layer 4 are sequentially arranged on the substrate 7, that is, the anode layer 6 of the OLED module is arranged on the front of the substrate 7, the organic layer 5 is arranged on the front of the anode layer, and the cathode layer 4 is arranged on the front of the organic layer 5.

[0038] A conductive film is coated on the front side of the substrate 7 and the surrounding side walls 71, wherein the conductive film on one of the substrate side walls 71 is connected to the anode in the OLED...

Embodiment 2

[0046] like Image 6 As shown, this embodiment is similar to Embodiment 1, the difference is that the OLED module adopts an inverted structure, wherein the cathode layer 4, the organic layer 5, and the anode layer 6 are sequentially arranged on the substrate 7, that is, the backside of the cathode layer 4 of the OLED module is arranged on the On the front side of the substrate 7 , the organic layer 5 is arranged on the front side of the cathode layer 4 , and the anode layer 6 is arranged on the front side of the organic layer 5 . The inverted structure of the OLED module changes the light output direction of the OLED display unit, and the image of the OLED display unit is displayed from the anode layer 6 through the encapsulation layer on the front of the anode layer 6. This light output method increases the aperture ratio, thereby increasing the The brightness of the OLED display unit.

[0047]

Embodiment 3

[0049] like Figure 7 As shown, it is a schematic structural view of an OLED display unit in this embodiment; an OLED display unit includes a substrate 7, an OLED module, and an encapsulation layer, and the OLED module is composed of an anode layer 6, an organic layer 5, and a cathode layer 4 that are stacked. The encapsulation layer is arranged around and on the front of the OLED module.

[0050] Wherein the OLED module adopts an inverted structure, and the cathode layer 4, the organic layer 5, and the anode layer 6 are sequentially arranged on the substrate 7, that is, the backside of the cathode layer 4 of the OLED module is arranged on the front side of the substrate 7, and the front side of the cathode layer 4 is arranged on the organic layer 5. An anode layer 6 is arranged on the front side of the layer 5, and an encapsulation layer is arranged on the front side of the anode layer 6.

[0051] A conductive film is coated on the front side of the substrate 7 and the surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com