DLP display screen system and splicing method thereof

A technology for display systems and display screens, which is applied to parts of TV systems, TVs, and color TVs. The effect of low cost and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The utility model is described below in conjunction with accompanying drawing:

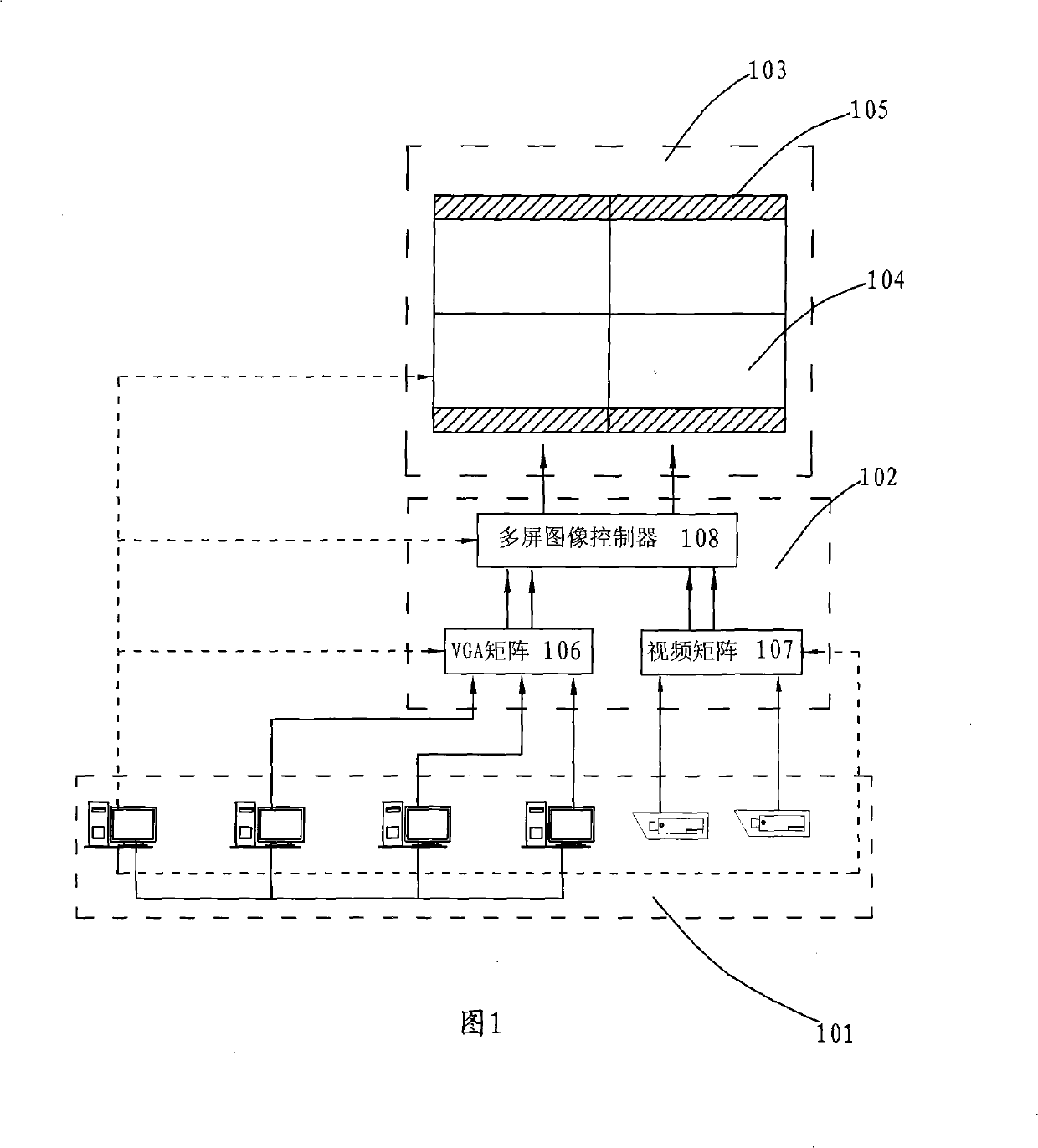

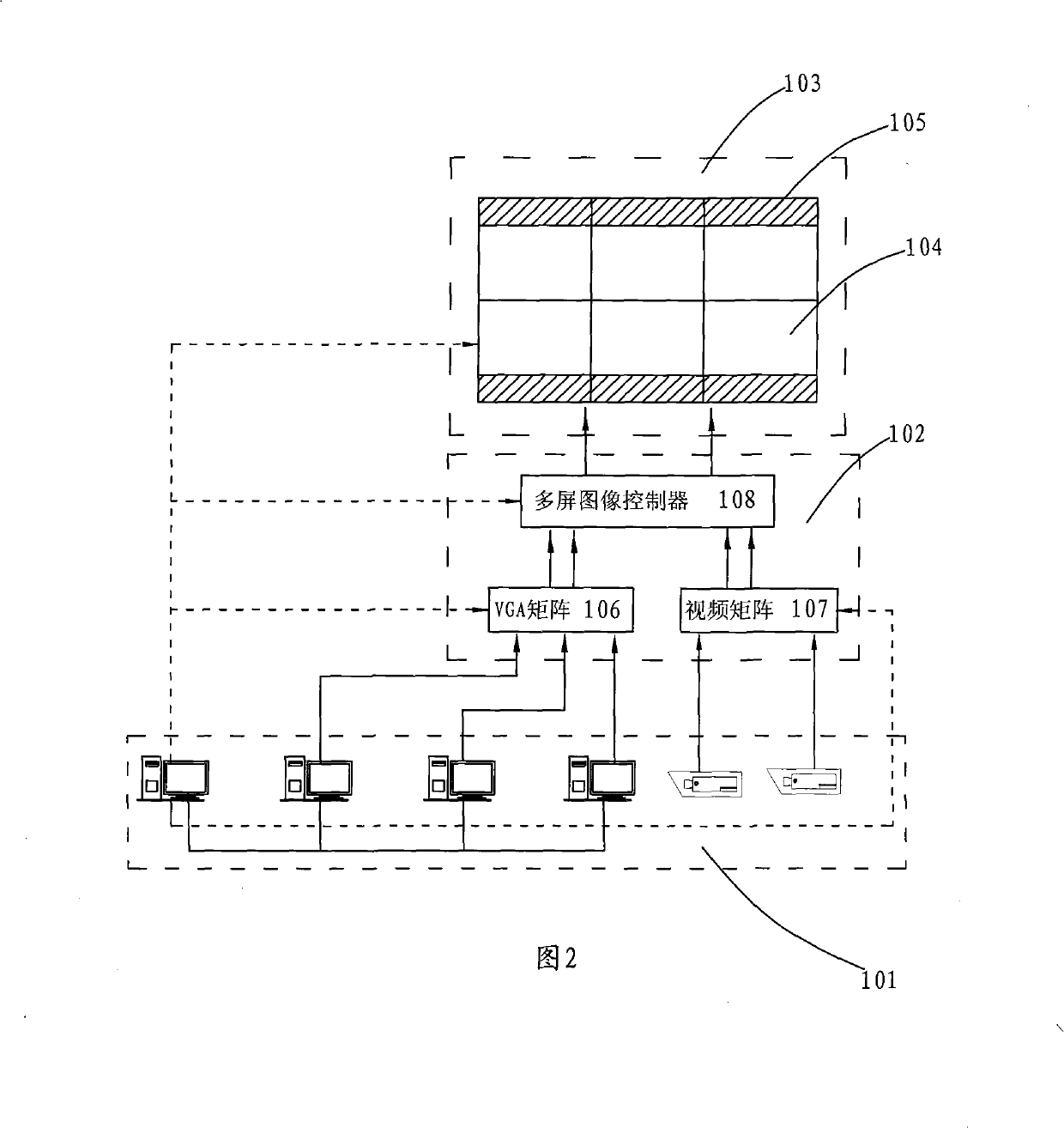

[0030] see figure 1 with figure 2 . As shown in the figure, the DLP display system includes: a signal input terminal 101, an information transmission unit 102 and a 16:9 DLP widescreen display terminal 103, wherein the signal input terminal 101 is connected to the information transmission unit 102, and the The information transmission unit 102 is connected to the 16:9 DLP widescreen display terminal 103 .

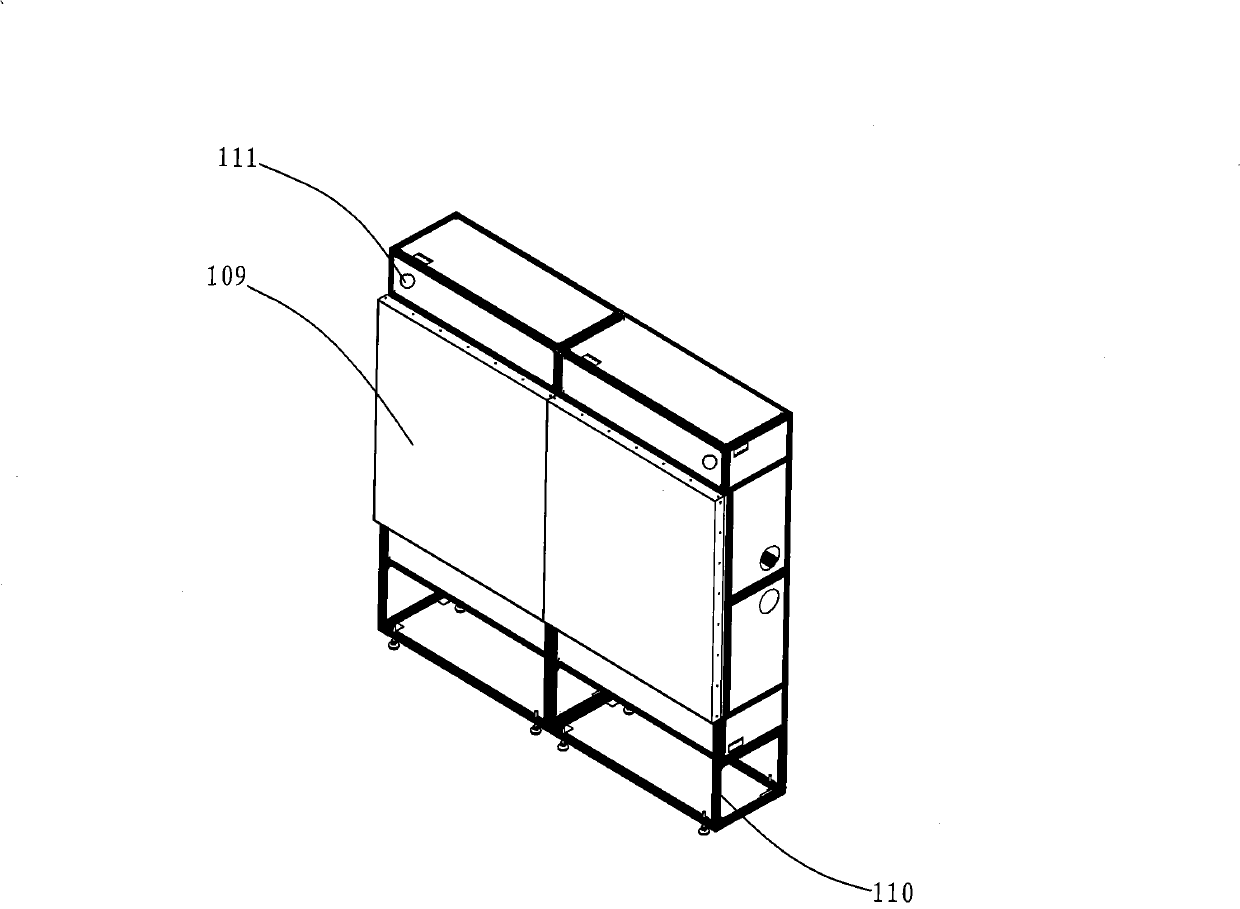

[0031] In the preferred technical solution of the present invention: the 16:9 DLP widescreen display terminal 103 includes a 16:9 DLP display 104 , and the 16:9 DLP display 104 is driven by a 16:9 optical engine 105 . The 16:9 optical engine 105 is installed above and / or below the 16:9 DLP display screen 104, and the installation position can be referred to in conjunction with image 3 A schematic diagram of the overall structure of a 16:9 DLP splicing screen in a DLP display screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com