CIS image acquisition method for bore diameter and bore number detection of printed circuit board

A printed circuit and image acquisition technology, applied in the field of image processing and computer vision, can solve the problems of complex image acquisition and manufacturing process of hole inspection machine, strict image registration requirements, and strict position requirements, and achieves the reduction of equipment cost and production process. Low complexity, low requirements for image registration, and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

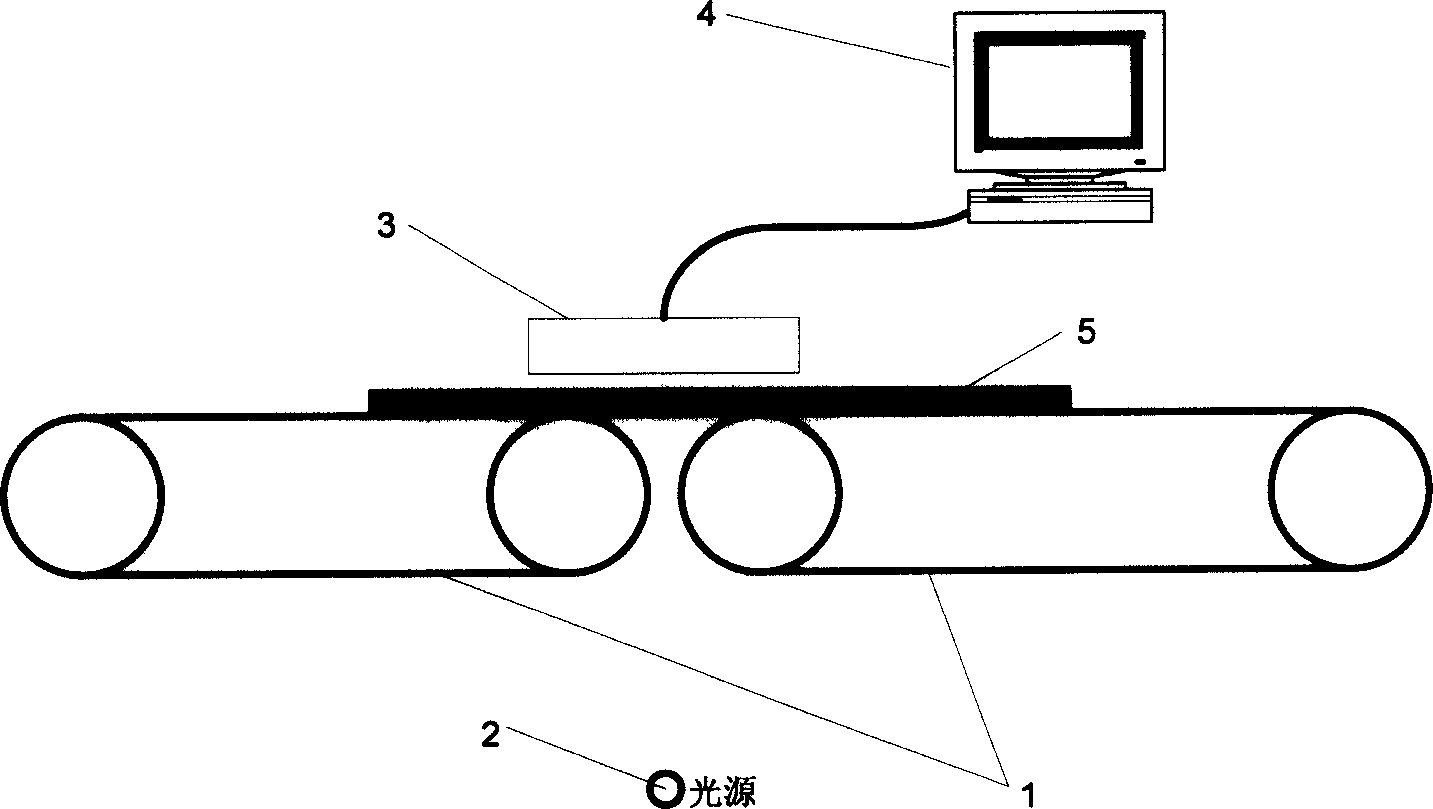

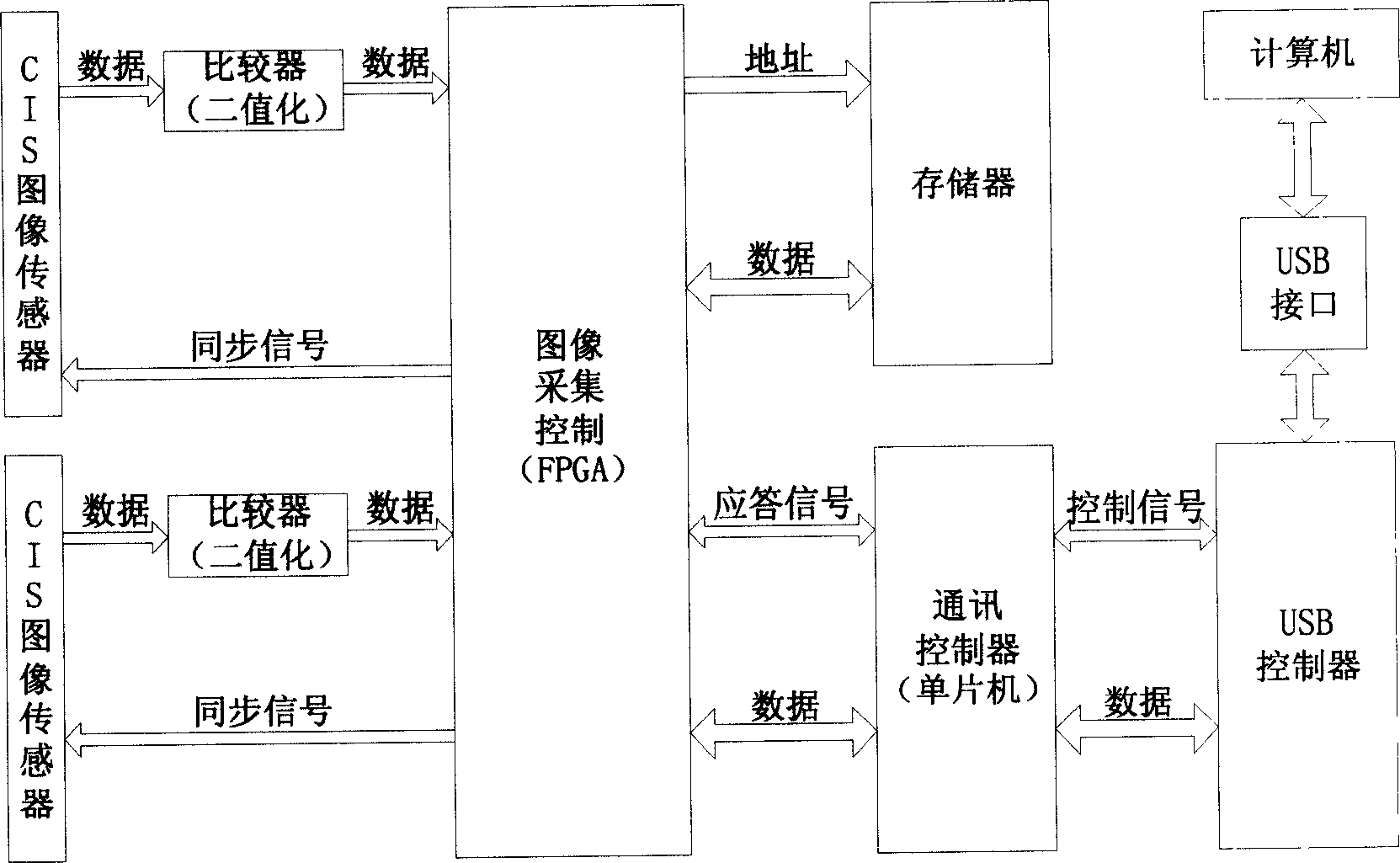

[0027] exist figure 1 Among them, the printed circuit board (5) to be detected is placed on the printed circuit board conveying device (1), and is driven by the motor to move along the surface of the conveying belt at a constant speed. The transmitted light source (2) is placed on two adjacent PCB conveying devices. Just below the slit between the rollers, the PCB printed circuit board is irradiated upward through the slit, and the light irradiated to the through hole on the circuit board can be received by the CIS image sensor of the image acquisition part (3) through the circuit board, and the formed The image is bright, but the place where there is no via hole on the circuit board is dark on the CIS image sensor because there is no light passing through. The brightness information obtained by the CIS image sensor is binarized, compressed and stored in the image acquisition The memory of part (3) is transmitted to the memory of computer (4) by the communication module of ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com